Key Features of the DUOMI CNC Drilling Machine

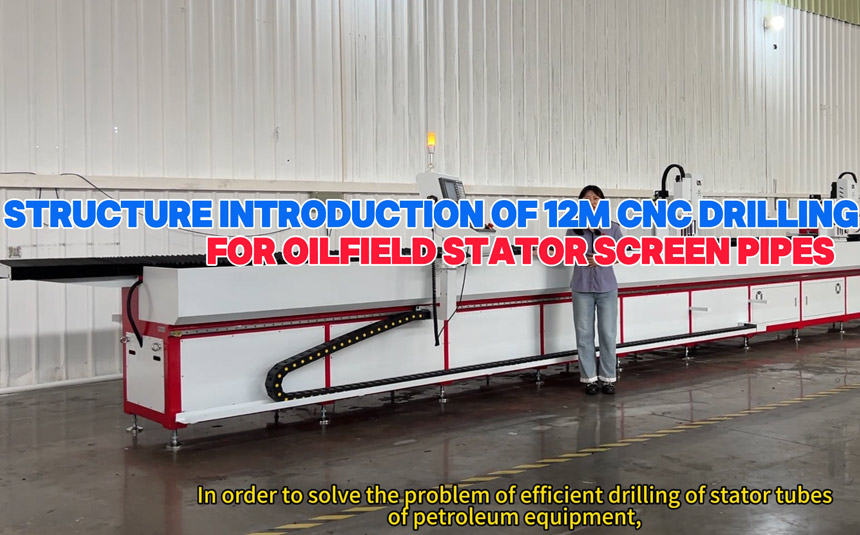

Massive Travel Range – Up to 12 Meters

Whether you're working with short brackets or 12-meter long industrial tubes, this machine scales with your production. Ideal for:

✅ Architectural metal profiles

✅ Automotive structural tubing

✅ Fitness equipment frames

✅ Solar panel supports

✅ Fence and gate manufacturing

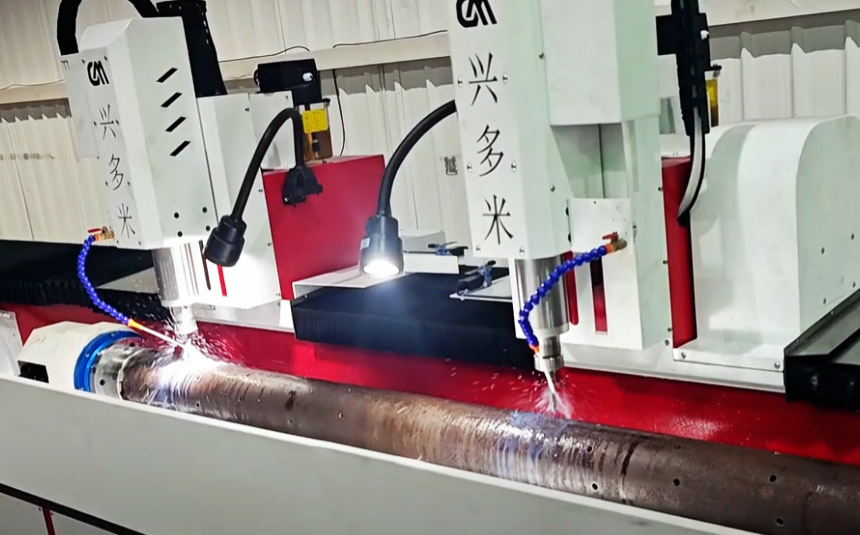

Dual Asynchronous Spindles = Double the Productivity

This unique feature lets both spindles work independently or simultaneously, drilling different hole sizes or mirrored layouts on opposite sides—no flipping required.

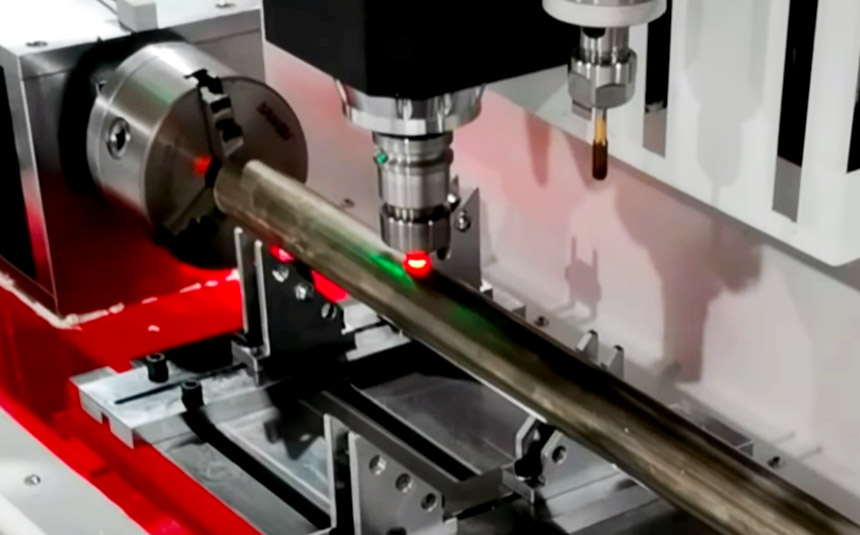

CNC Control for Extreme Accuracy

Program complex drilling patterns using G-code or easy touchscreen software. Eliminate human error and cut setup time in half.

Thermal Friction Drilling Optional

Drill chip-free holes in thick-walled round pipes without distortion. Perfect for stainless steel, aluminum, and carbon steel tubes up to 8mm wall thickness.

Industries That Benefit Most

Fitness & Gym Equipment Manufacturing

Easily drill and tap holes in square and round tubing for machine frames and supports with consistent spacing—no need for jigs or templates.

Structural Steel & Construction

Drill bolt holes in long architectural profiles and heavy steel tubing used in commercial structures, with the accuracy required for field assembly.

Automotive & EV Chassis

From battery pack brackets to thick-walled tubular frames, DUOMI CNC delivers drilling solutions that meet today's automotive precision standards.

Metal Furniture & Railing Systems

Perfect holes in thin or thick-walled pipes help reduce welding steps and enhance the visual finish of your designs.

Perforation Drilling for Pipeline Screens in Oil Equipment

This drilling process is specifically designed for creating precise perforations in pipeline screens used in oilfield equipment. With high accuracy and consistent hole spacing, our CNC drilling machines ensure superior filtration performance and durability under extreme working conditions. Ideal for manufacturing sand control screens, slotted liners, and filter pipes in the oil and gas industry.

Why Choose DUOMI CNC?

Here's what sets DUOMI CNC apart from others on the market:

✅ Trusted Worldwide – Machines installed in over 40 countries.

✅ User-Friendly Interface – Minimal training required.

✅ Customizable – Choose number of spindles, workholding options, and drill sizes.

✅ All-in-One Functionality – Drill, tap, mark, and more.

✅ Reliable After-Sales Support – Remote guidance and local service options.

✅ And yes—our machines are built to last, tested on real production floors, and ready to handle your toughest jobs.

See the ROI in Months, Not Years

The DUOMI CNC pipe and profile drilling machine doesn't just add power to your shop—it pays for itself fast. Benefits include:

✅ Up to 50% reduction in manual labor

✅ 300% increase in hole consistency

✅ Faster job turnaround

✅ Less scrap = more profit

✅ No more outsourcing. No more rework. Just precision and performance at your fingertips.

Final Thoughts

If you're drilling into long metal profiles or thick-walled tubing, it's time to ditch the old methods and move to a smarter solution. The CNC Drilling Machine for Metal Profiles and Tubes from DUOMI CNC is engineered for real-world production—fast, flexible, and future-ready.

Contact DUOMI CNC today to request a demo or quote. Let's build better, faster—together.

Request A Quote

Request A Quote