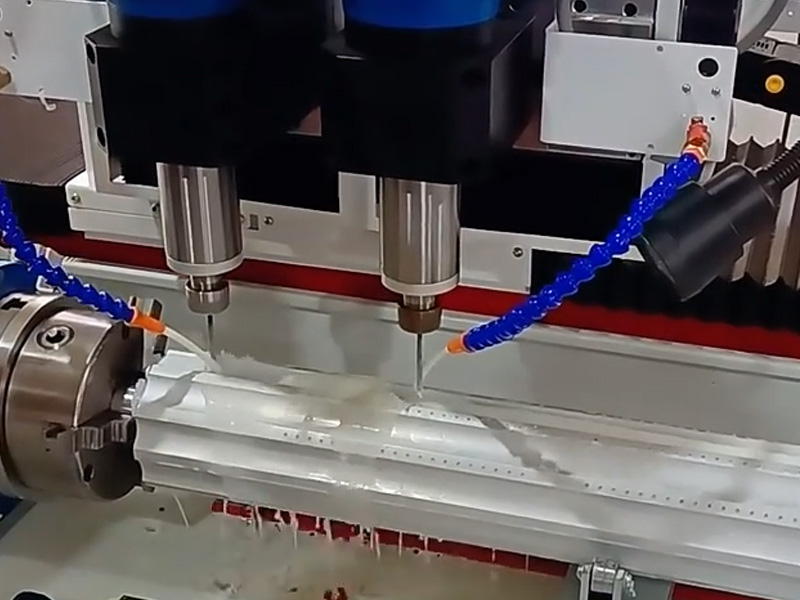

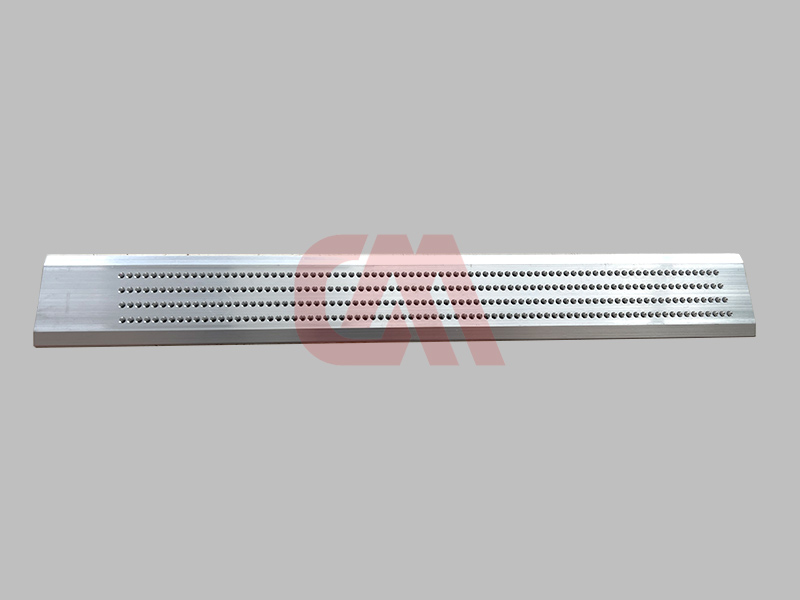

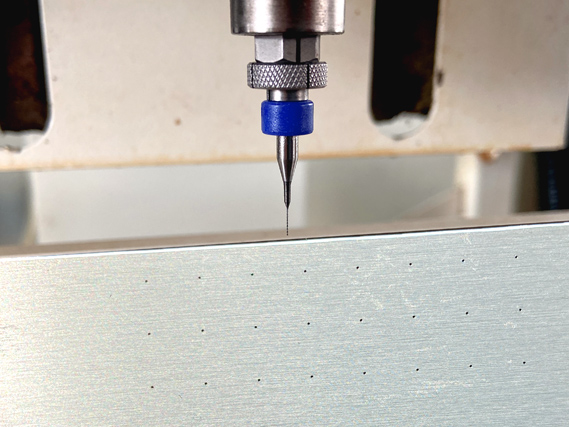

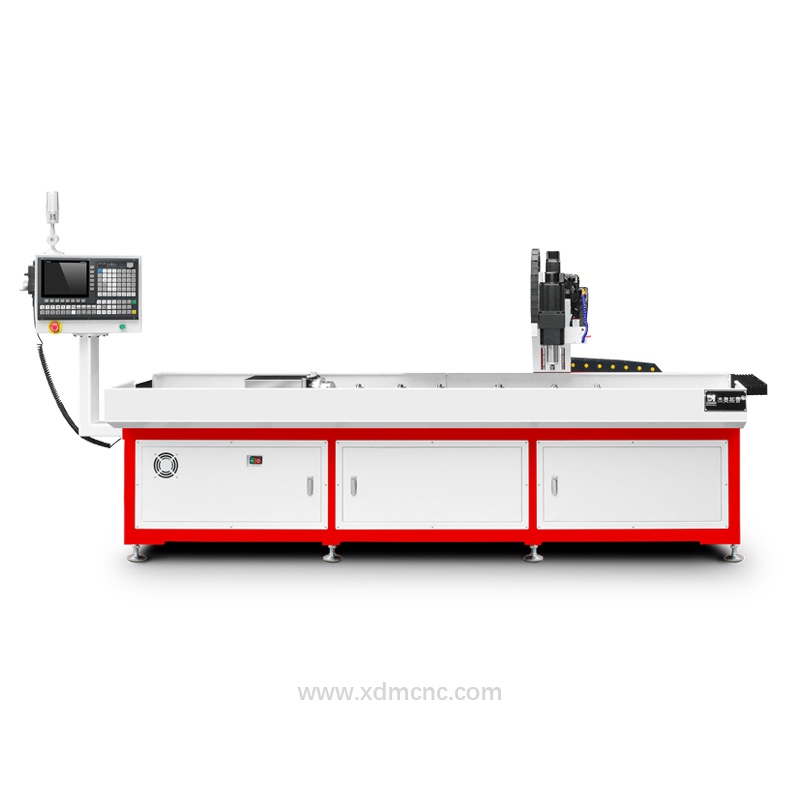

High Precision Dual-Spindle aluminium drilling tapping machine

CNC Drilling & Tapping Machine

Model: DNC-1003DT(R1)

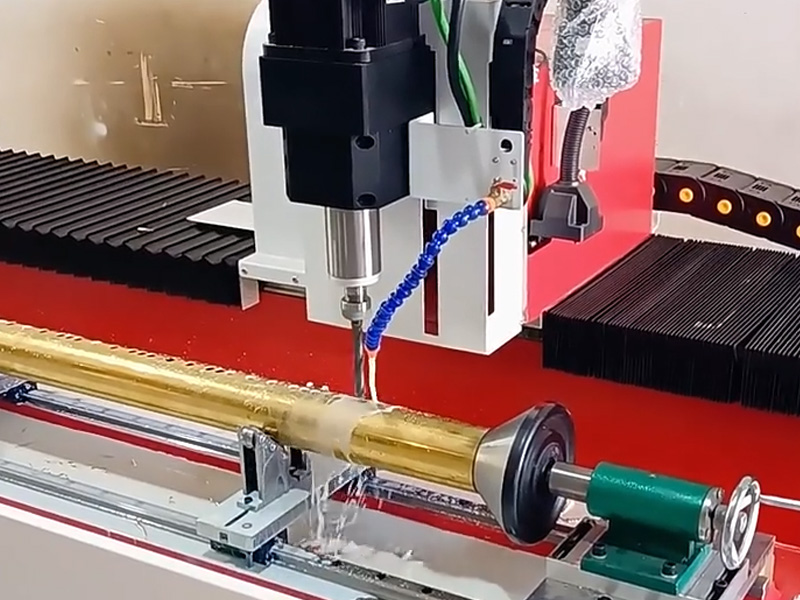

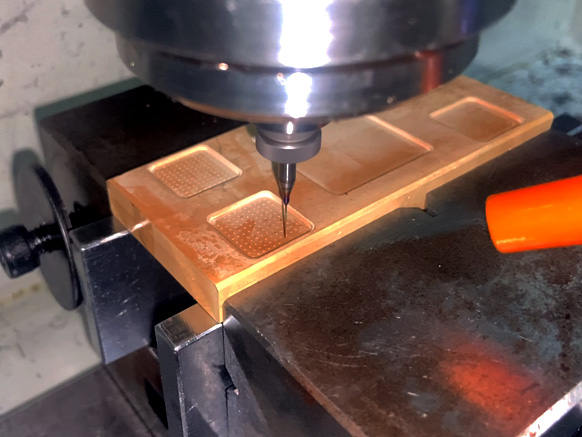

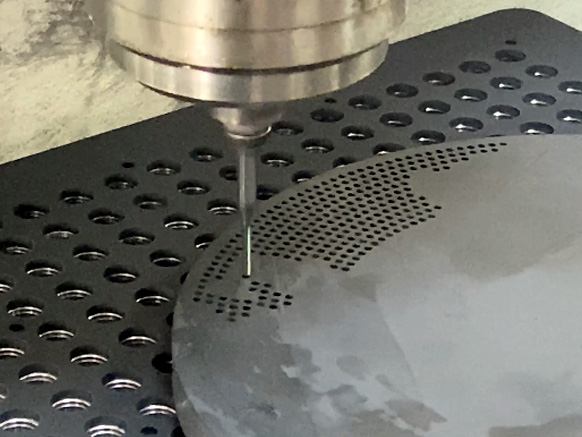

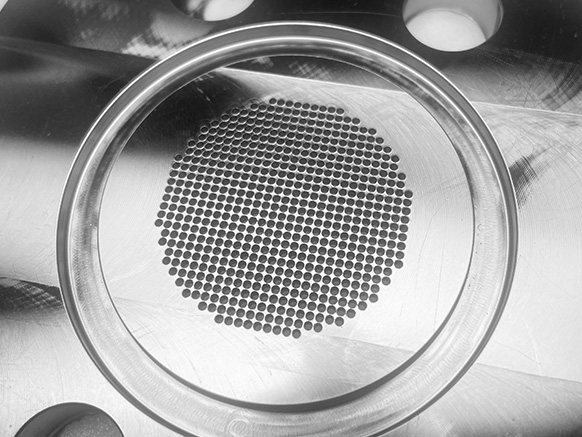

Function: CNC Drilling and tapping

Application Materials: Iron, Copper, Aluminium, Brass, Steel, Zinc, Platinum etc.

Feature

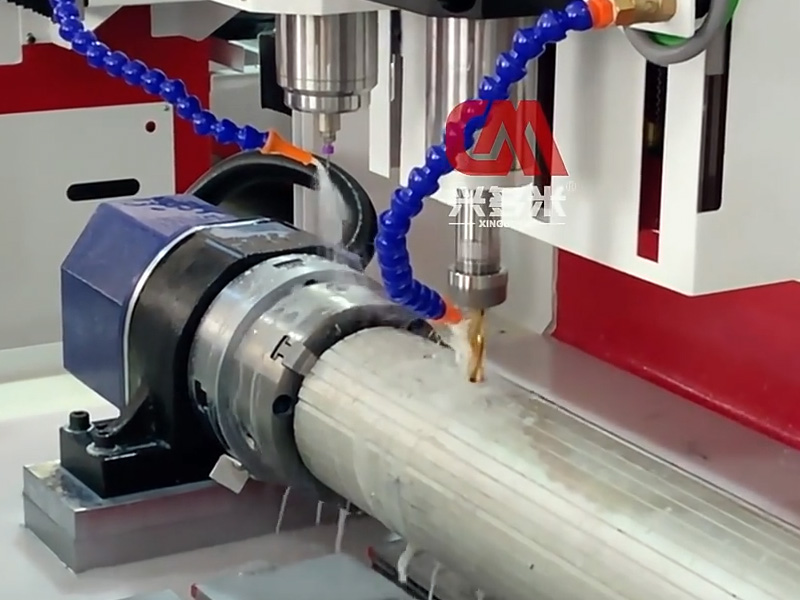

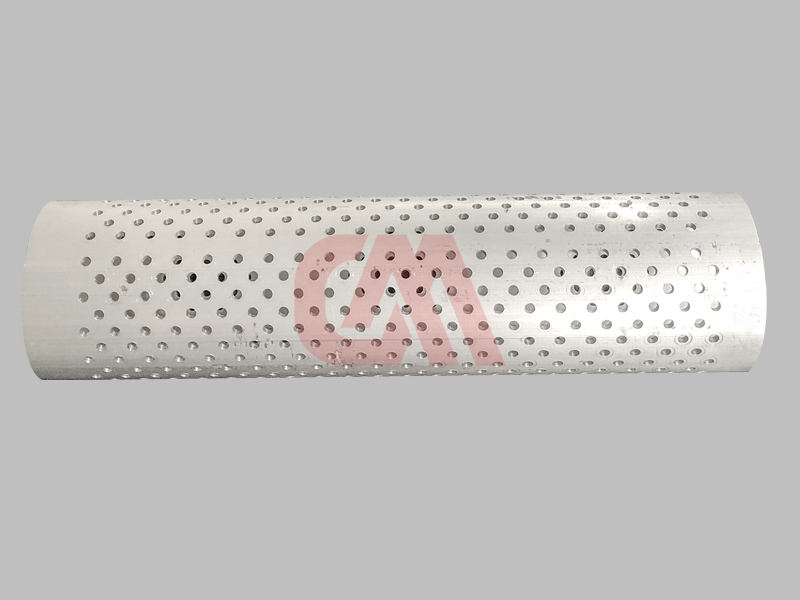

This model is a multi-functional four-axis form drilling and tapping equipment, and can also be used as an ordinary drilling equipment. The rotary shaft adopts servo motor with high-precision harmonic reducer, which has high rotation positioning accuracy and can be processed at any angle of 360 degrees.

Processing square tube, round tube and special-shaped tube are switched by changing fixtures.

Optional guide rail type pneumatic fixture with easy clamping and fast product switching clamping speed to improve work efficiency.

Achieve unmatched precision and efficiency with our High Precision Dual-Spindle Aluminium Drilling And Tapping Machine, designed specifically for high-volume, high-accuracy drilling in aluminum materials. Whether you're in the automotive, aerospace, or manufacturing industry, this machine is built to streamline your production process and deliver superior results.

Lead time (days) : 7 to 10 working days. (Standard Configuration)

Tip: Our CNC drilling and tapping machines support custom non-standard designs, machine color customization, and OEM branding. Start now to purchase and customize your own equipment, please contact us.

Request A Quote

Request A Quote