High-Precision CNC Drilling & Tapping Machines – UK Supplier

CNC Drilling & Tapping Machine

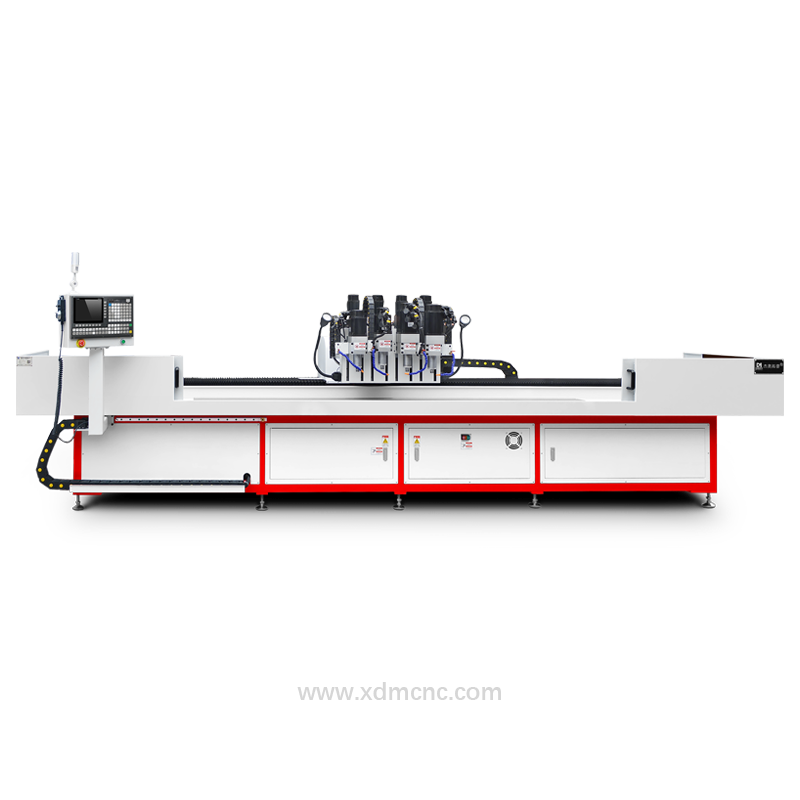

Model: DNC-4030DT

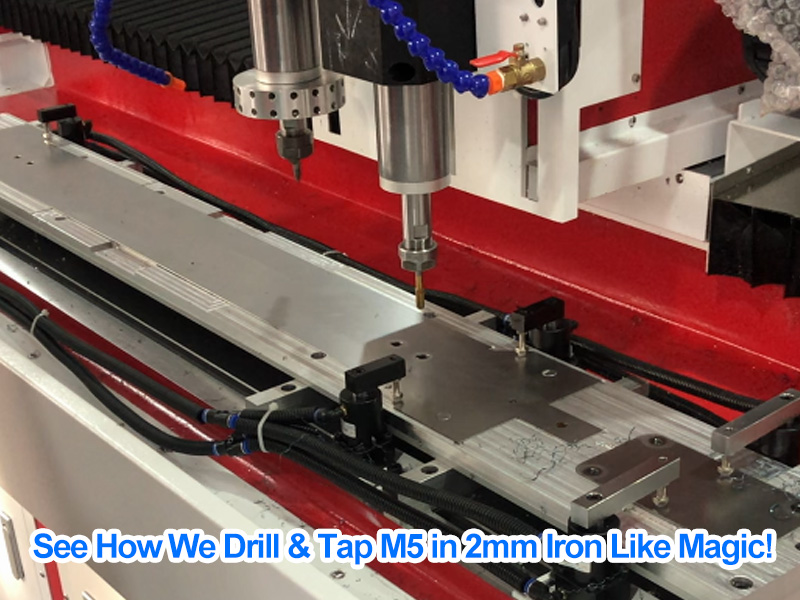

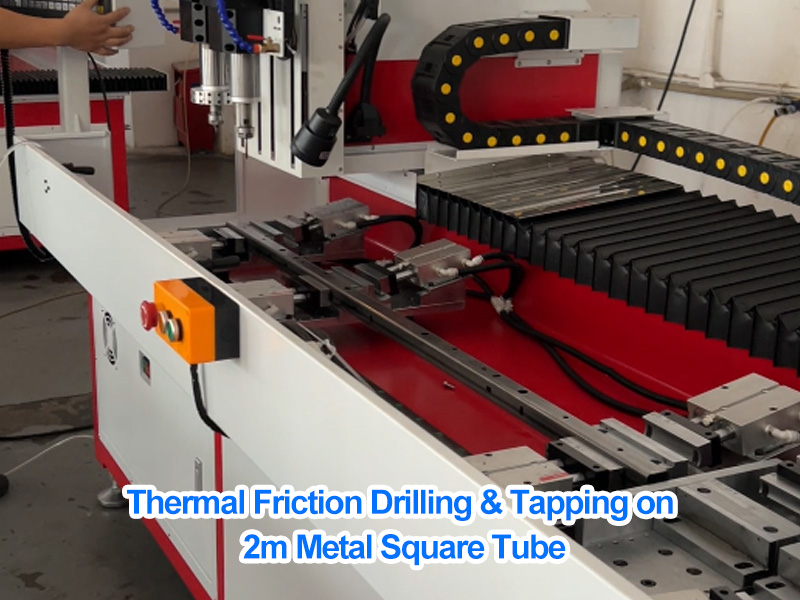

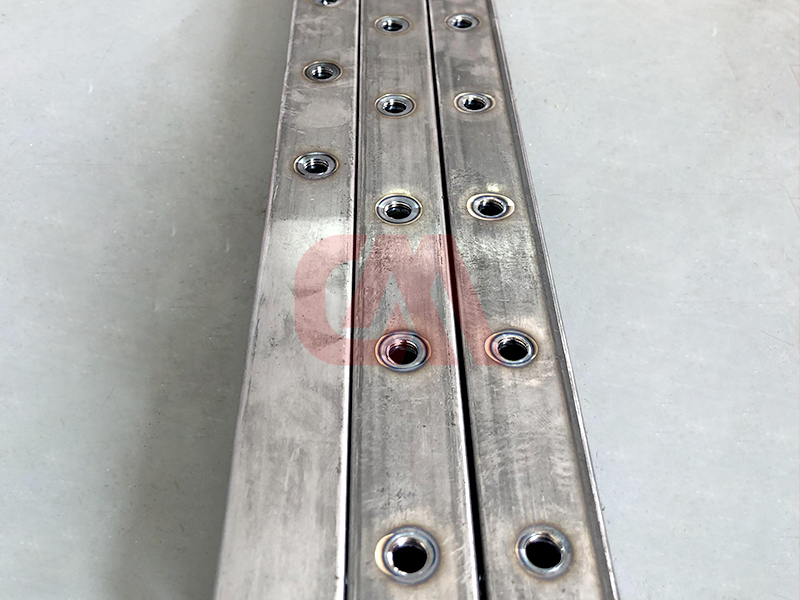

Function: CNC drilling and tapping, Thermal friction drilling, flow drilling

Application Materials: Iron, Copper, Aluminium, Brass, Steel, Zinc, Platinum etc.

Feature

High-speed drilling and tapping for up to 4-metre profiles.

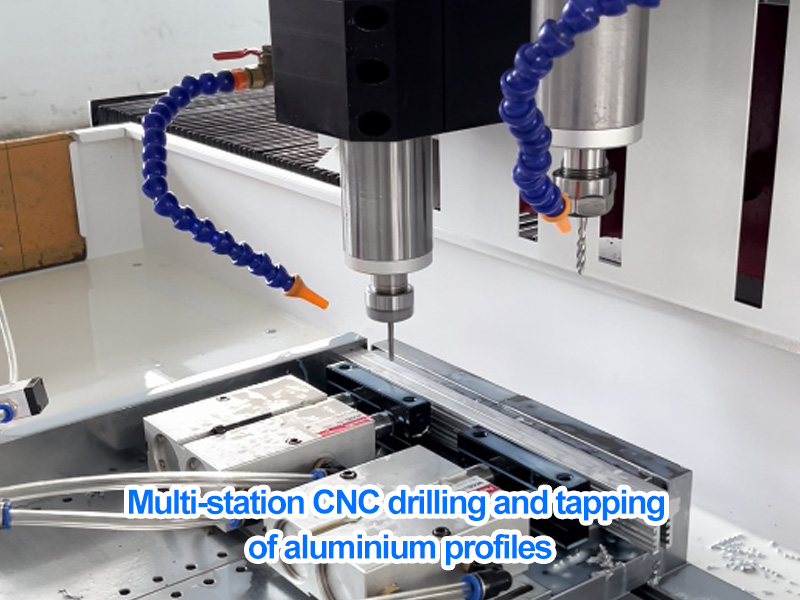

Works perfectly with aluminium, steel, stainless steel, and copper.

Stable CNC control system, easy programming, and training.

UK technical support and 24/7 global after-sales service.

Two spindles are capable of performing both conventional drilling and tapping as well as thermal friction drilling and tapping.

Metal parts support multi-station continuous processing, while long profiles can be drilled and tapped from 1 to 4 meters in length.

Boost your productivity with DUOMI CNC drill and tap solutions for aluminium profiles, steel tubes, and stainless steel components. Looking for a CNC drilling and tapping machine supplier in the UK? Contact DUOMI CNC for competitive prices, fast delivery, and expert support.

Lead time (days) : 30 working days. (Standard Configuration)

Tip: Our CNC drilling and tapping machines support custom non-standard designs, machine color customization, and OEM branding. Start now to purchase and customize your own equipment, please contact us.

Request A Quote

Request A Quote