CNC Thermal Drill-Mill-Tap Machine with 24-Tool Magazine

CNC Drilling & Tapping Machine

Model: DHM-2560N24

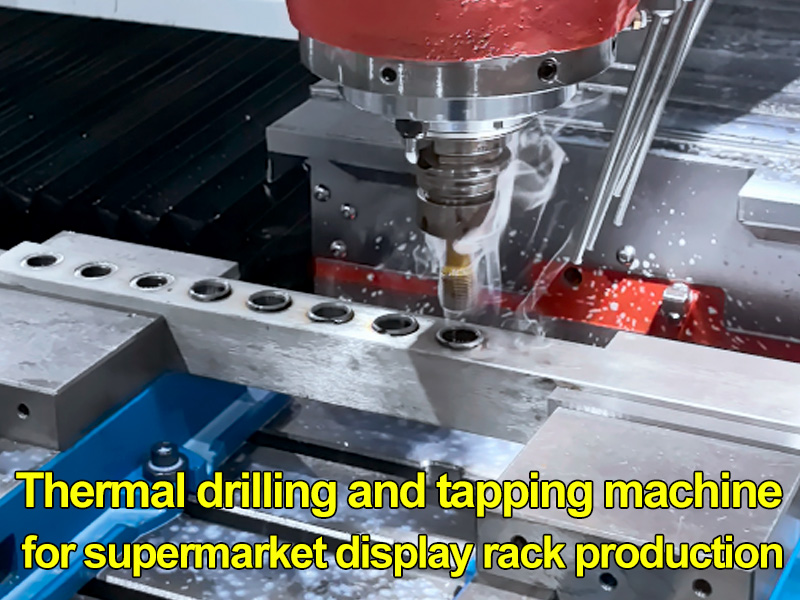

Function: CNC Thermal Drilling, Milling, Tapping

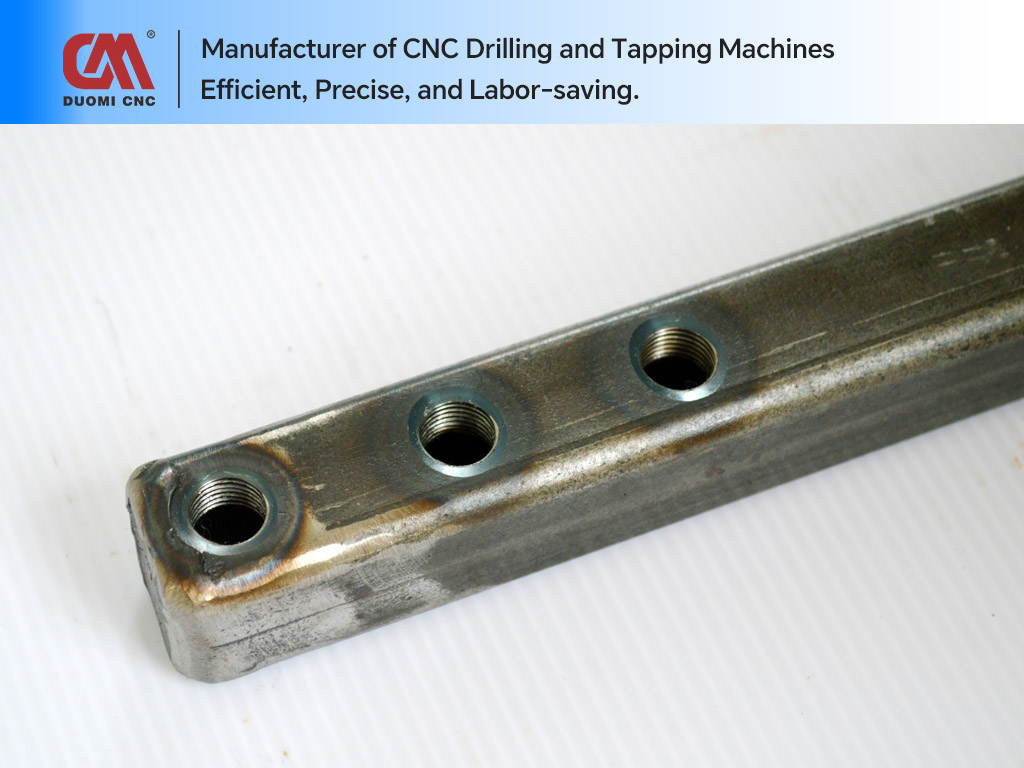

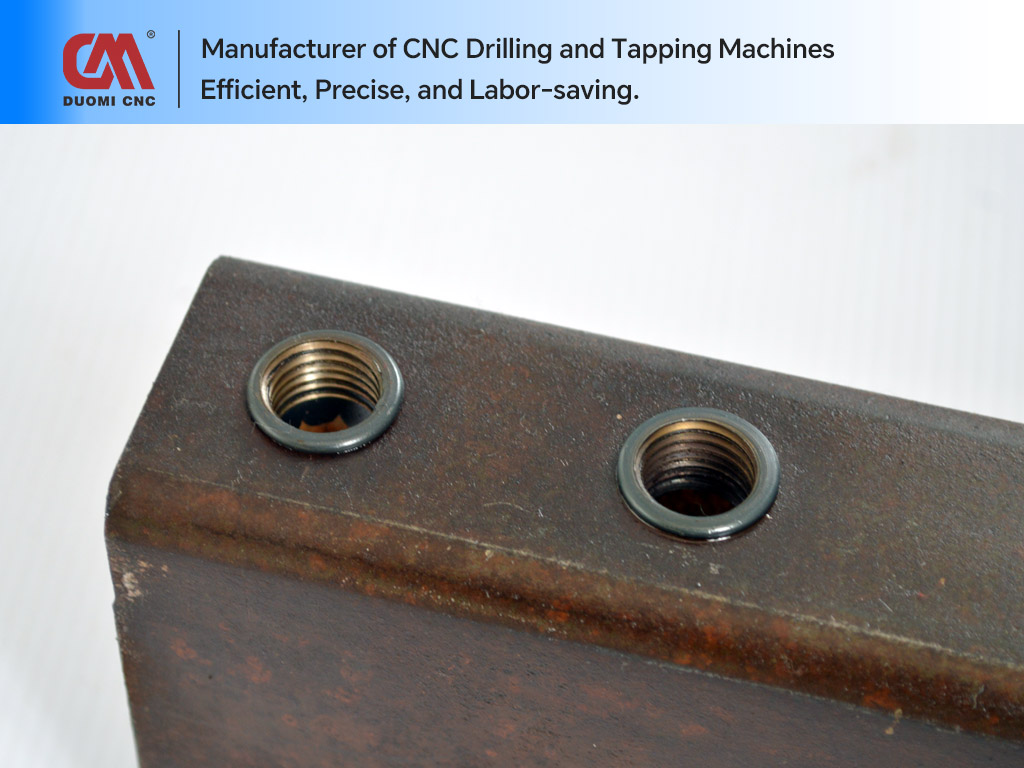

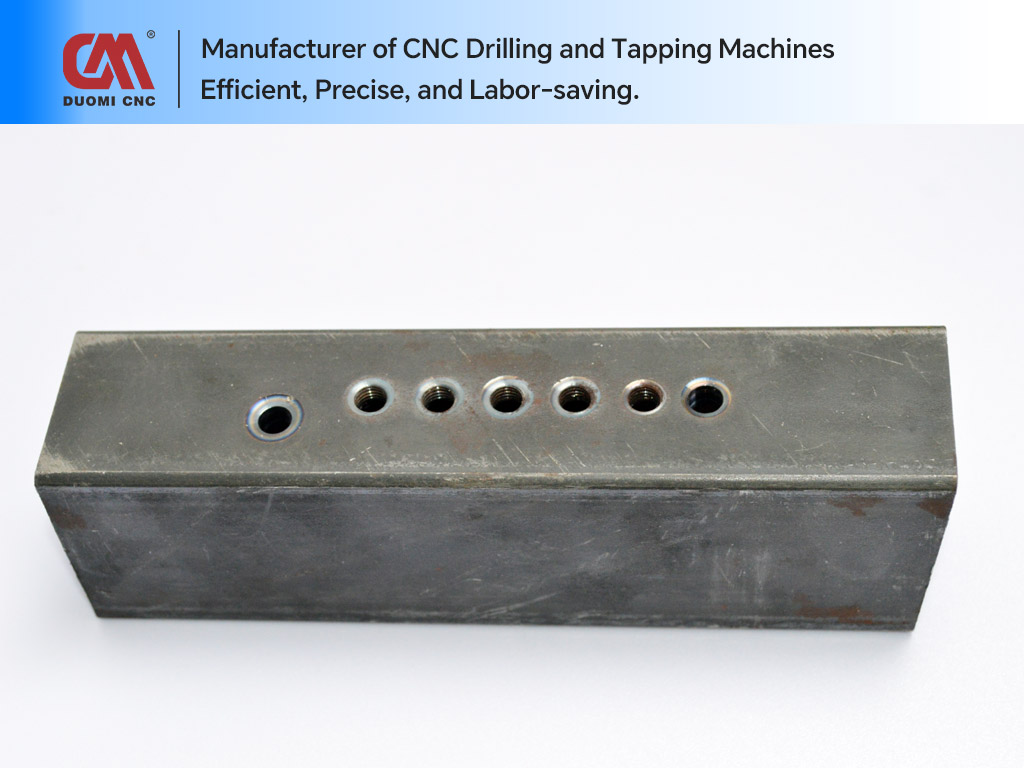

Application Materials: Long Metal Profiles and Round Steel Tubes

Feature

The CNC Thermal Drill-Mill-Tap Machine with a 24-tool magazine is an advanced solution that integrates drilling, milling, and tapping into one highly efficient system. Designed to improve productivity and reduce production costs, this all-in-one machine is particularly suitable for manufacturers who require precision, speed, and flexibility in handling different metal materials such as stainless steel, carbon steel, aluminum, and alloy tubes.

Lead time (days) : 30 working days. (Standard Configuration)

Tip: Our CNC drilling and tapping machines support custom non-standard designs, machine color customization, and OEM branding. Start now to purchase and customize your own equipment, please contact us.

Request A Quote

Request A Quote