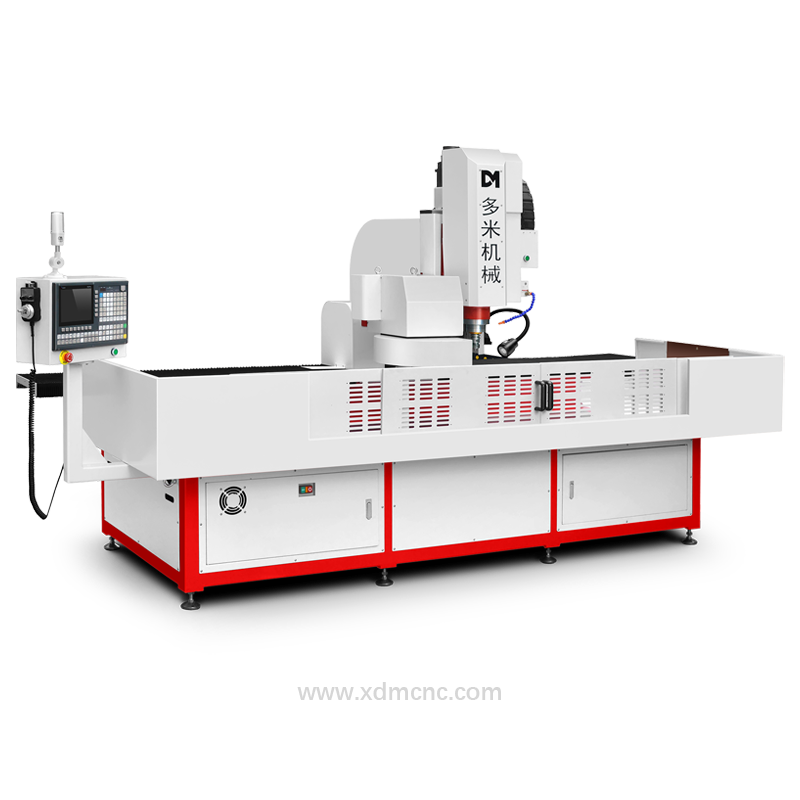

CNC Thermal Drilling and Tapping Solution for Square and Round Steel Pipes

CNC Drilling & Tapping Machine

Model: DHM-1003DT(R1)

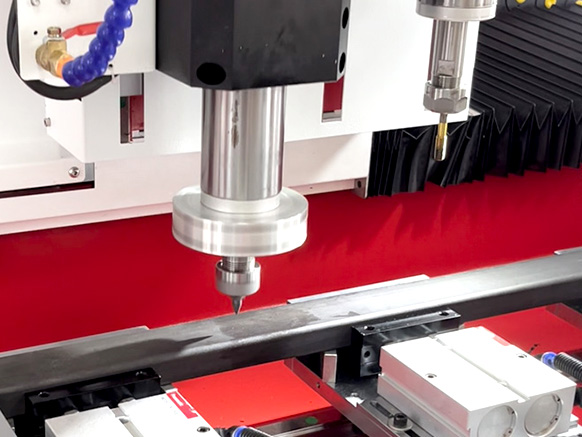

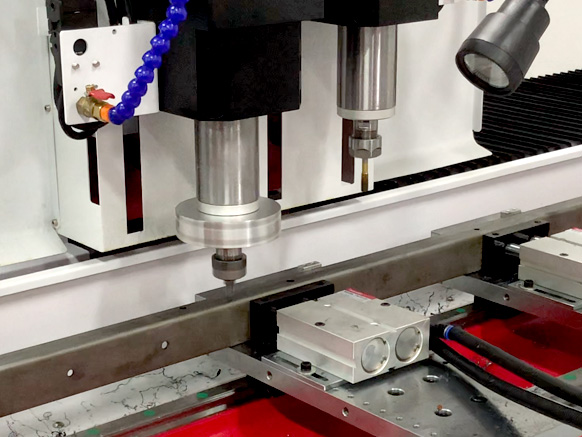

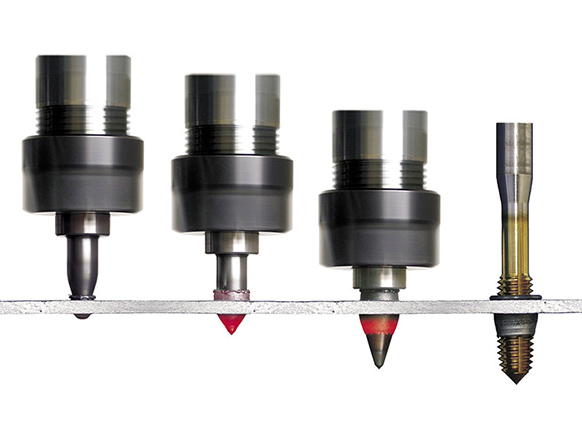

Function: Flow Drilling and Tapping

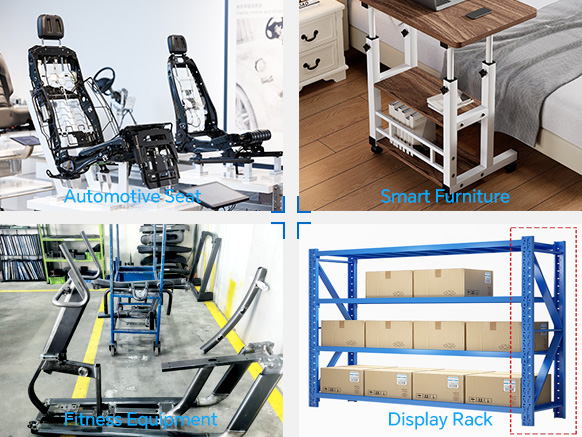

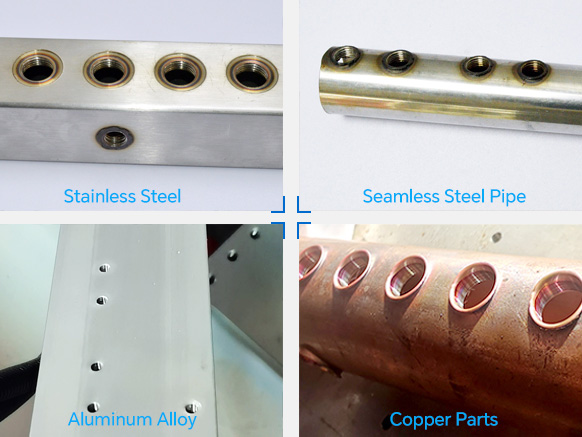

Application Materials: Iron, Copper, Aluminium, Brass, Steel, Stainless Steel, Zinc, Platinum etc.

Feature

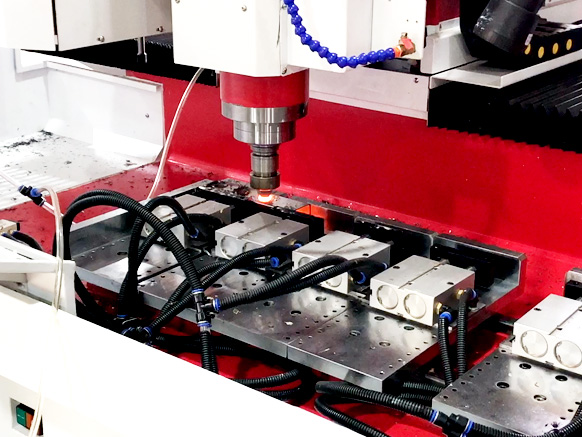

This model is a multi-functional four-axis Thermal drilling and tapping equipment, and can also be used as an ordinary drilling equipment.

The rotary shaft adopts servo motor with high-precision harmonic reducer, which has high rotation positioning accuracy and can be processed at any angle of 360 degrees.

Processing square tube, round tube and special-shaped tube are switched by changing fixtures.

Optional guide rail type pneumatic fixture with easy clamping and fast product switching clamping speed to improve work efficiency.

CNC & Thermal Drilling Machine Manufacturer – Custom & Standard Models.

Choose from standard or custom CNC & flow drilling machines. High performance guaranteed!

Lead time (days) : 7 to 10 working days. (Standard Configuration)

Tip: Our CNC drilling and tapping machines support custom non-standard designs, machine color customization, and OEM branding. Start now to purchase and customize your own equipment, please contact us.

Request A Quote

Request A Quote