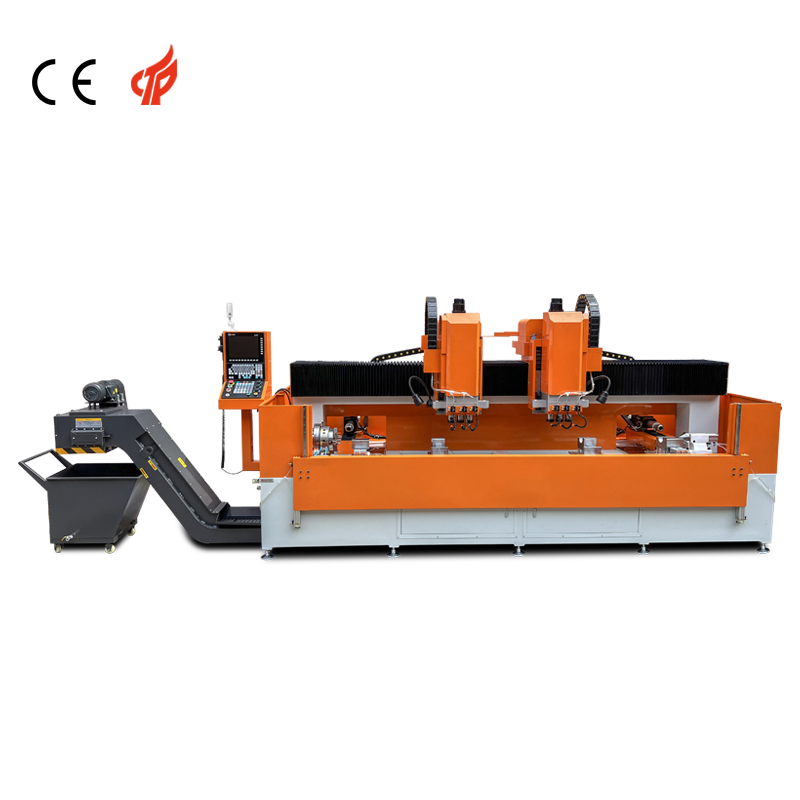

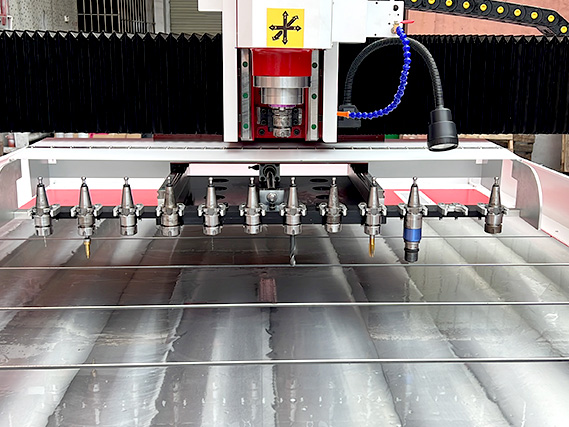

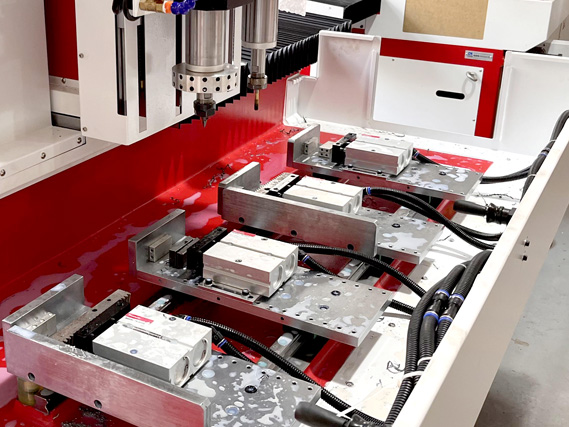

4-Axis CNC Drill & Tap Machine for Steel Profiles

CNC Drilling & Tapping Machine

Model: DNC-3003DDDD(R1)

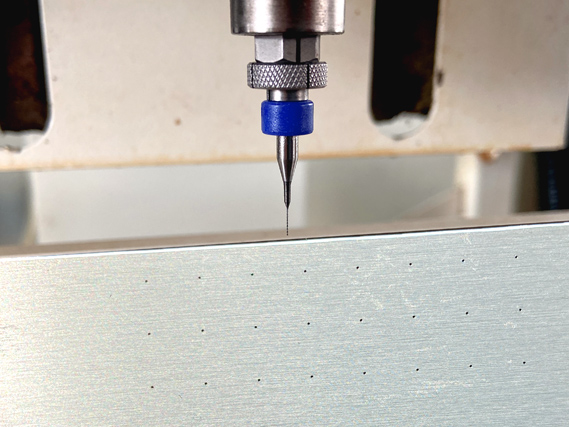

Function: Drilling

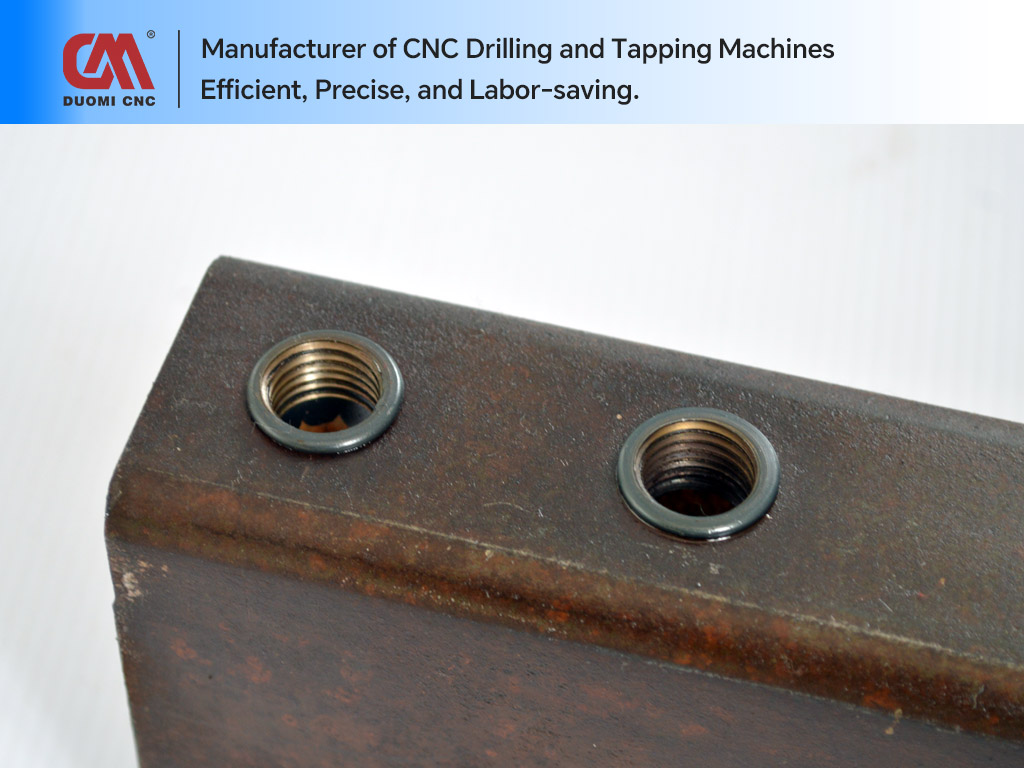

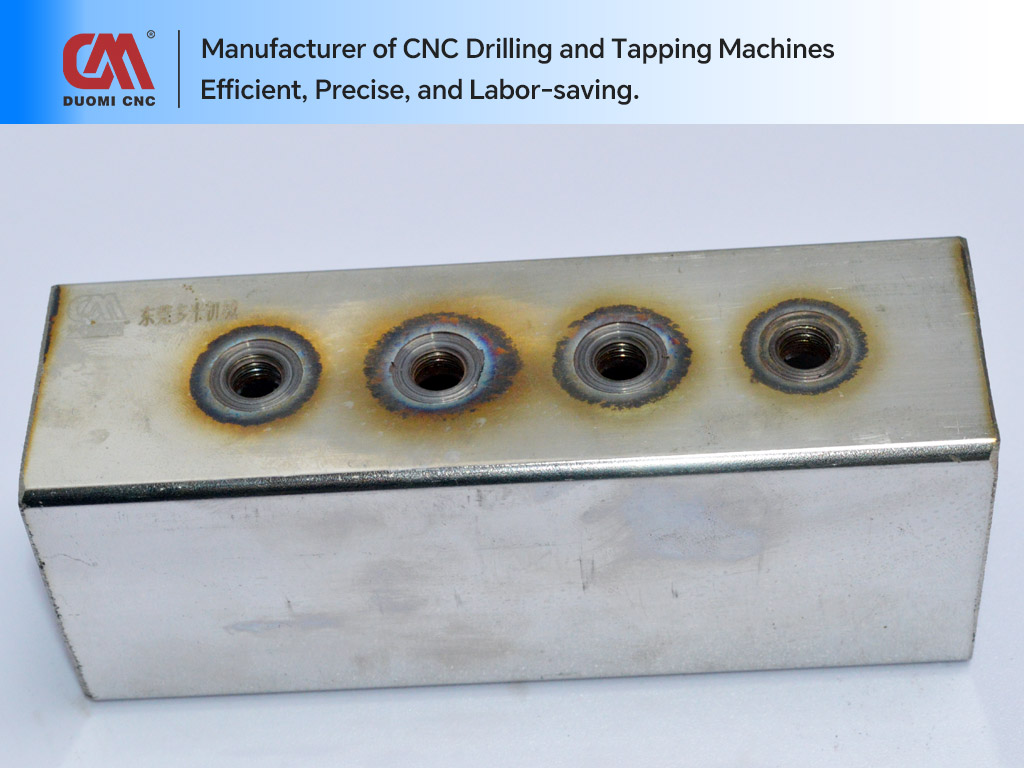

Application Materials: Iron, Copper, Aluminium, Brass, Steel, Zinc, platinum etc.

Feature

4-Axis CNC Drill & Tap Machine for Steel Profiles

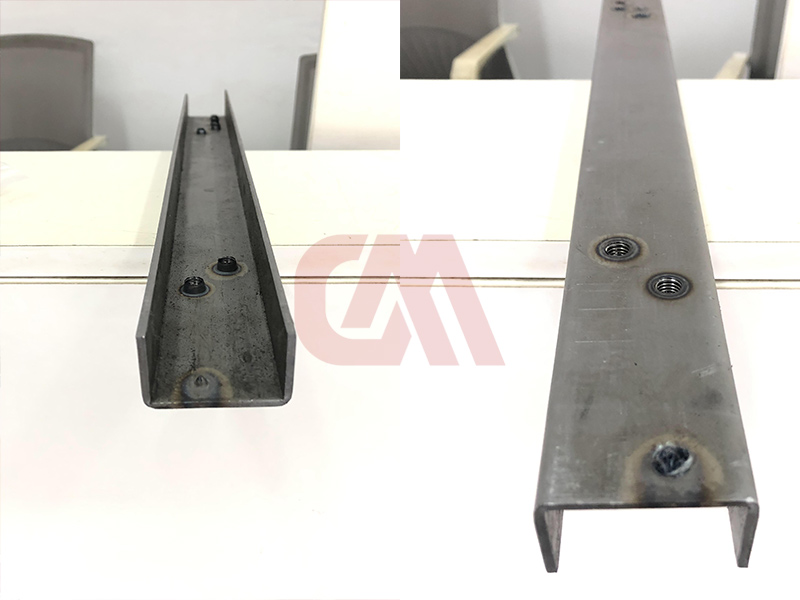

Our structural steel beam CNC drilling machines are ideal for:

Small, medium and large-sized structural steel fabricators;

High-volume steel fabrication and metal processing;

Heavy manufacturing;

These machines are integral throughout the production stages in the steel fabrication sector, especially when precision and efficiency are paramount. They are indispensable during the initial metal processing phases and when fabricating components with exact specifications.

As a foremost manufacturer of CNC Drilling Machines, we cater to various industries with precision-engineered machines. Our CNC Drilling Machines are manufactured using high-quality components and cutting-edge technology. To ensure the highest standards, our quality examiners rigorously test each machine against multiple parameters. Additionally, our CNC Drilling Machines are available in diverse sizes and specifications to meet our clients' specific requirements.

Lead time (days) : 30 working days. (Standard Configuration)

Tip: Our CNC drilling and tapping machines support custom non-standard designs, machine color customization, and OEM branding. Start now to purchase and customize your own equipment, please contact us.

Request A Quote

Request A Quote