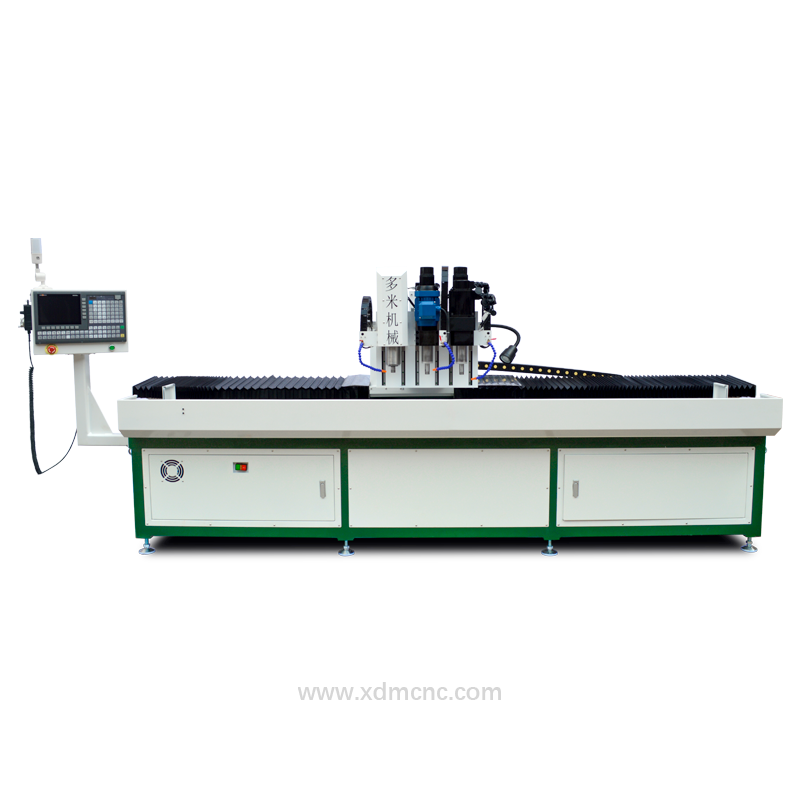

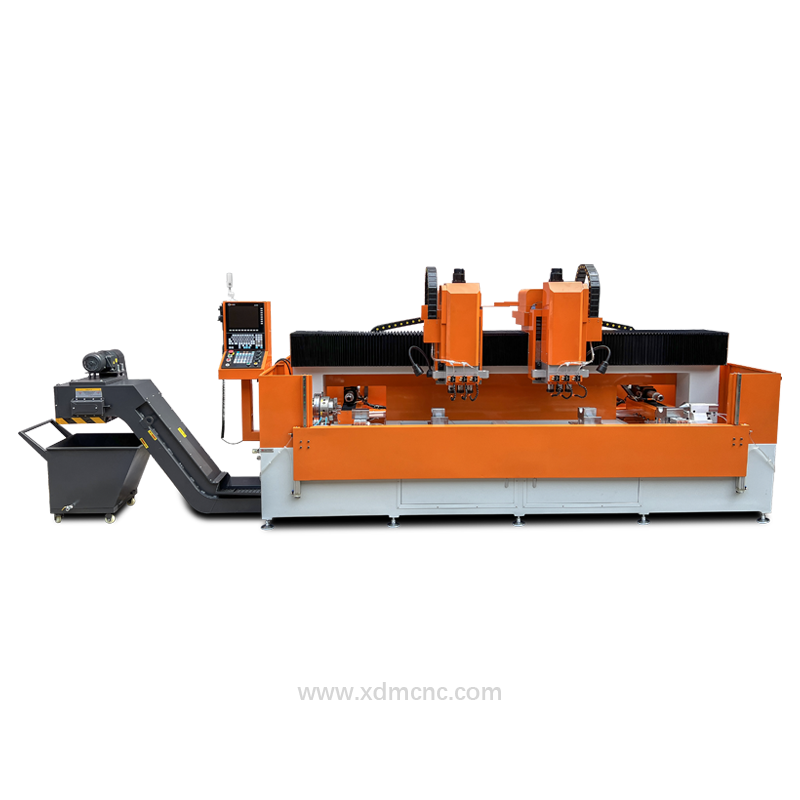

High-Precision Motor Rotor Orienter CNC Slotting Machine

CNC Drilling & Tapping Machine

Model: DNC-550C

Function: Cutting & Slotting

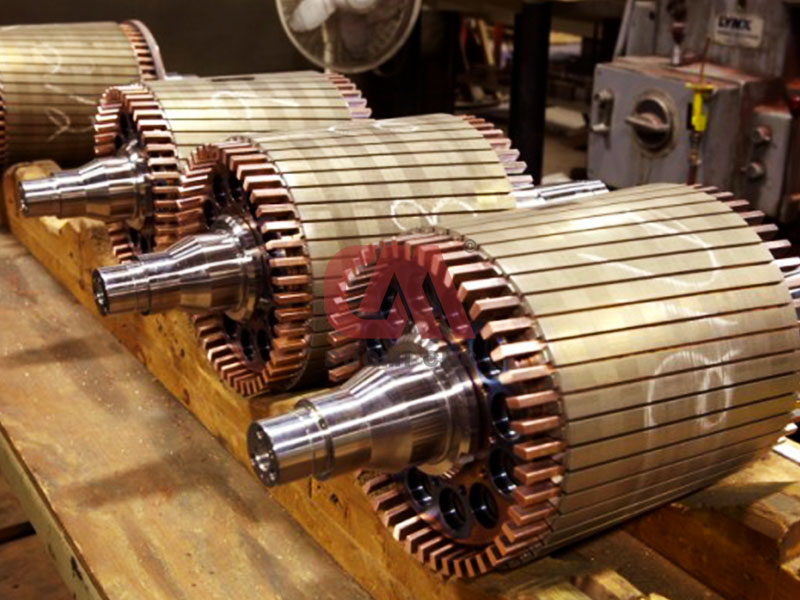

Application Materials: Iron, Copper, Aluminium, Brass, Steel, Zinc, Platinum etc.

Feature

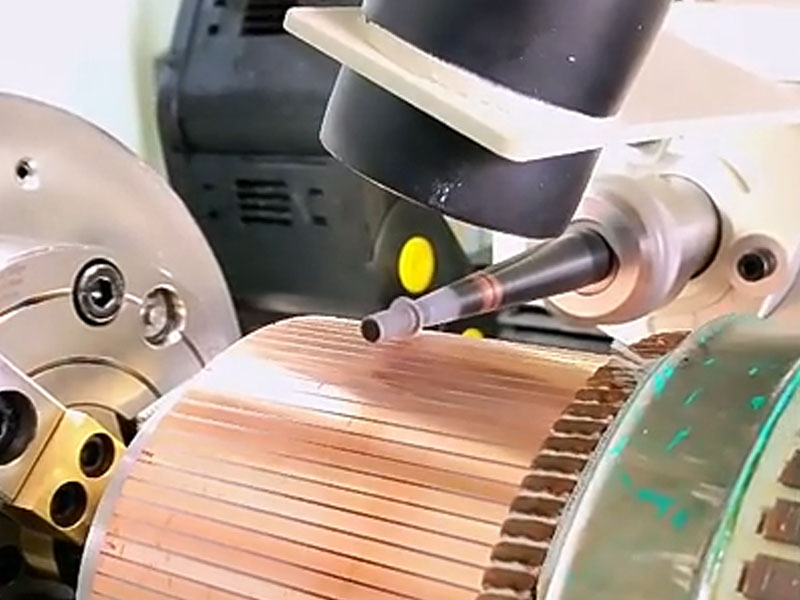

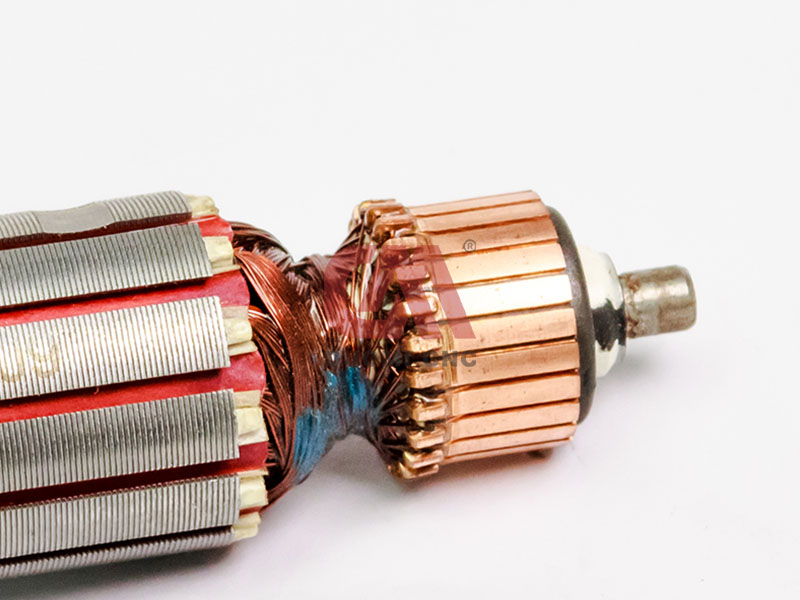

This model is a CNC Slotting Machine developed for motor rotor commutator slot cutting.

With CCD visual positioning system, it automatically scans and identifies the slot to ensure that the processing slot is not biased.

Full servo motor transmission control provides good positioning accuracy and high stability.

With industrial vacuum cleaner, when the cutting spindleis cutting, the industrial vacuum cleaner will suck the residue out of the machine tool to form chipless processing.

The rotary shaft adopts servo motor with high-precision harmonic reducer, which hashigh rotation positioning accuracy and can be processed at any angle of 360 degrees.

DNC-550C High-Precision CNC Slotting&Cutting Machine, CCD Visual Positioning, Auto Identification for Motor Rotor & Commutator

Lead time (days) : 30 working days. (Standard Configuration)

Tip: Our CNC drilling and tapping machines support custom non-standard designs, machine color customization, and OEM branding. Start now to purchase and customize your own equipment, please contact us.

Request A Quote

Request A Quote