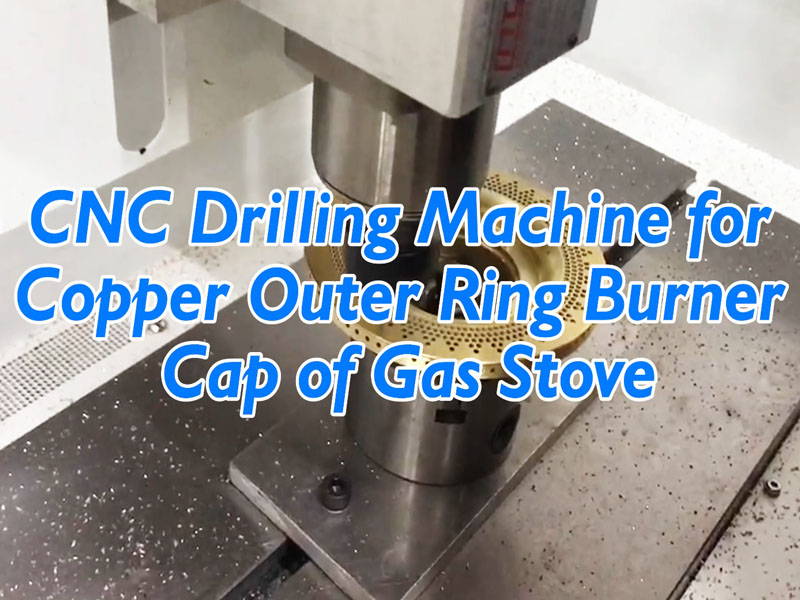

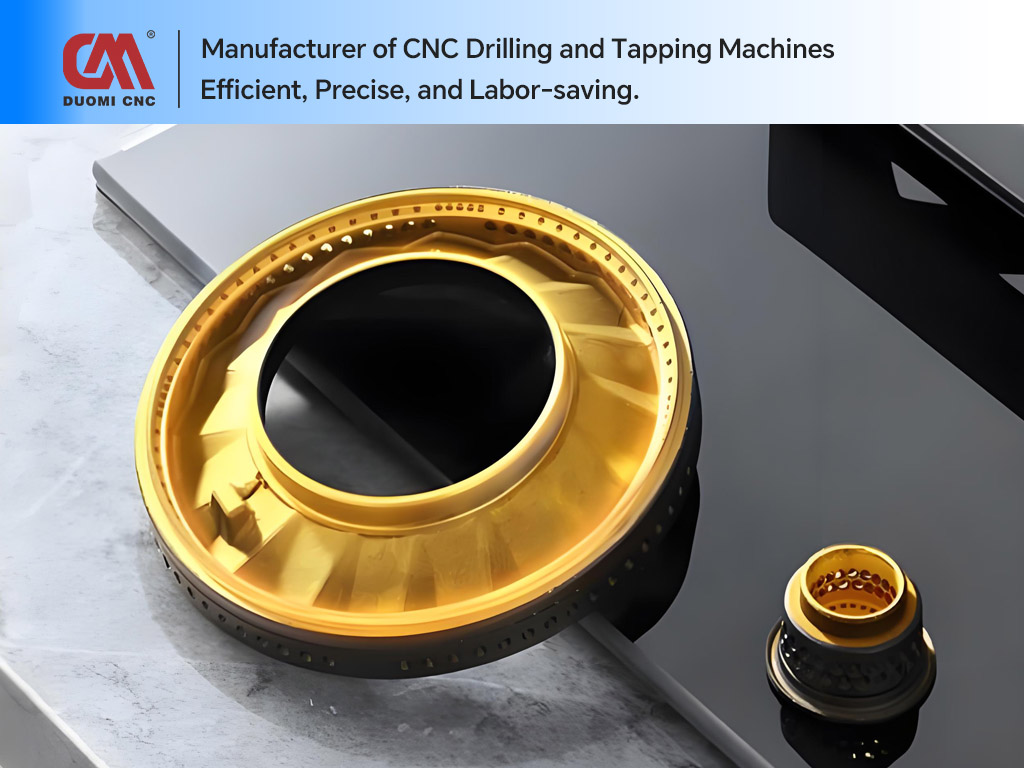

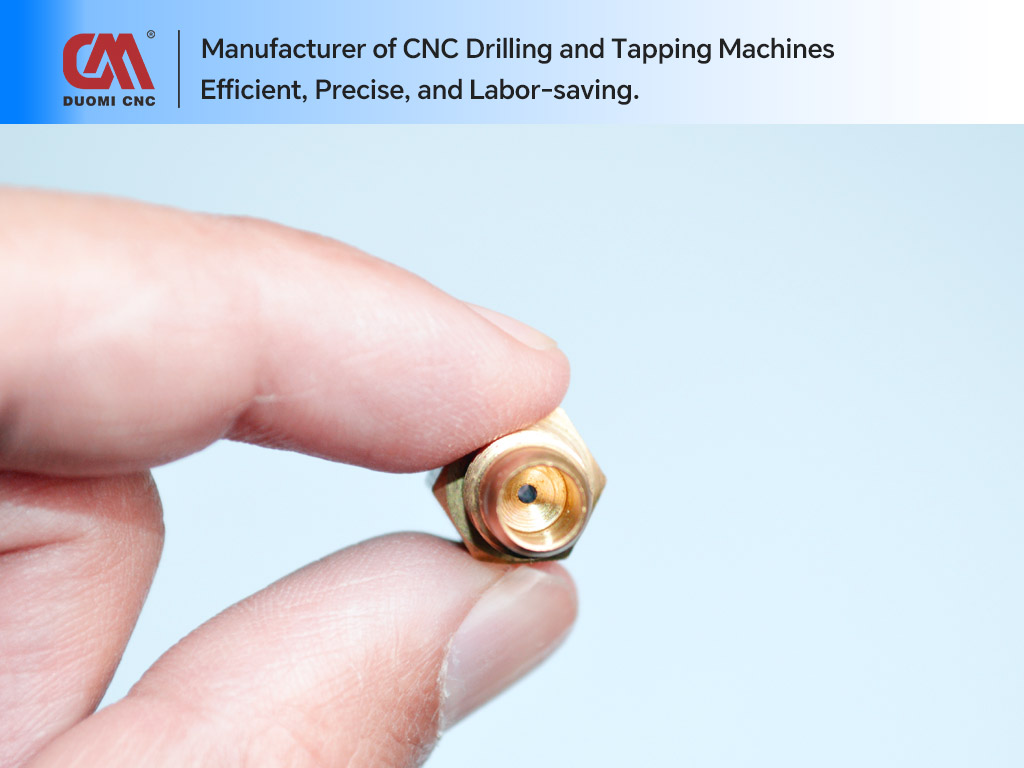

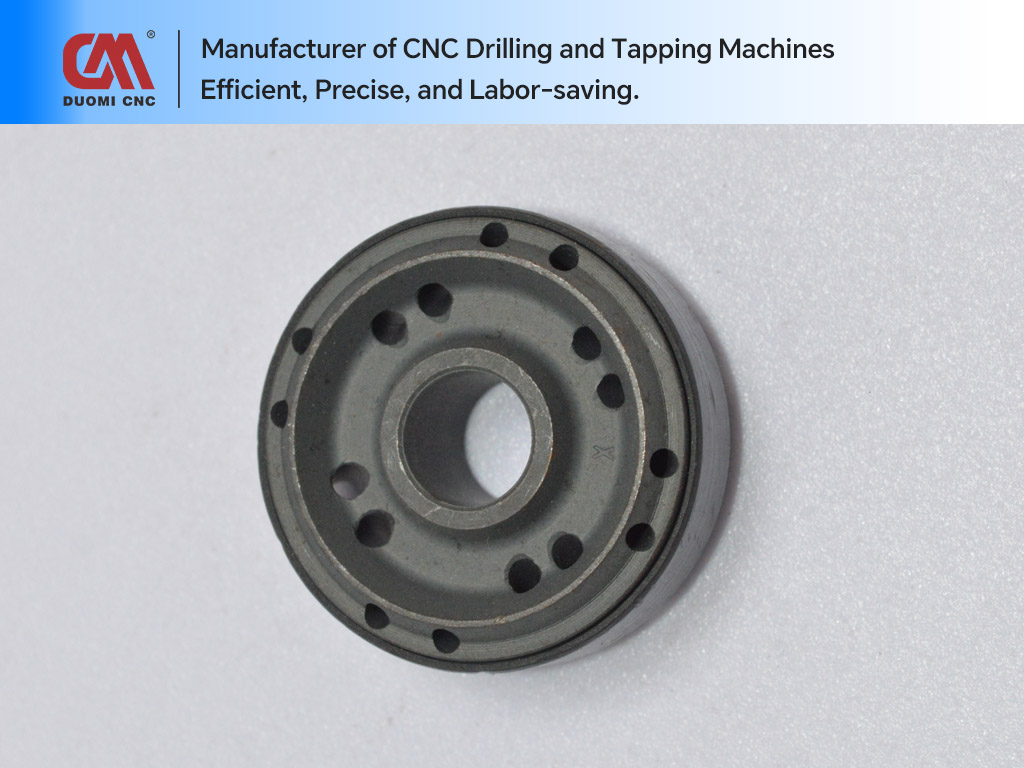

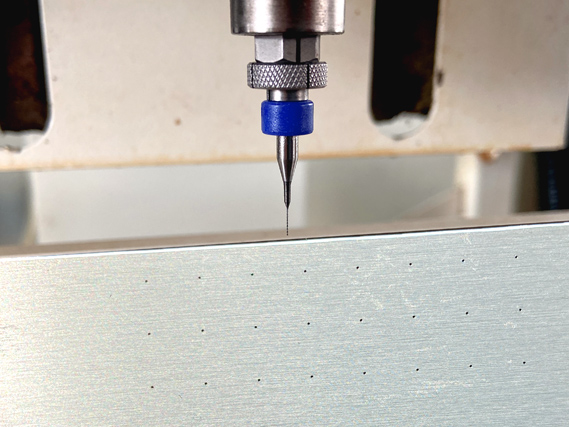

Drilling on cap of gas burner over cnc drill machine

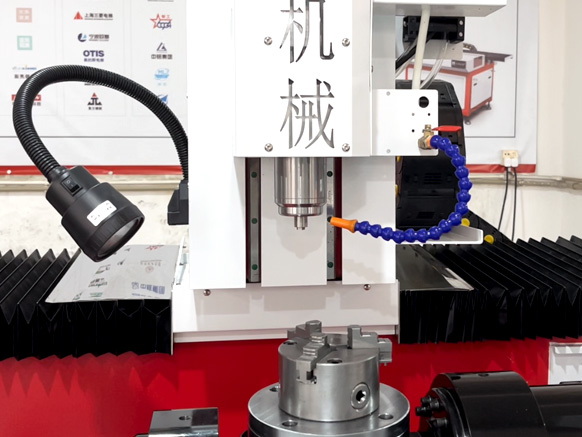

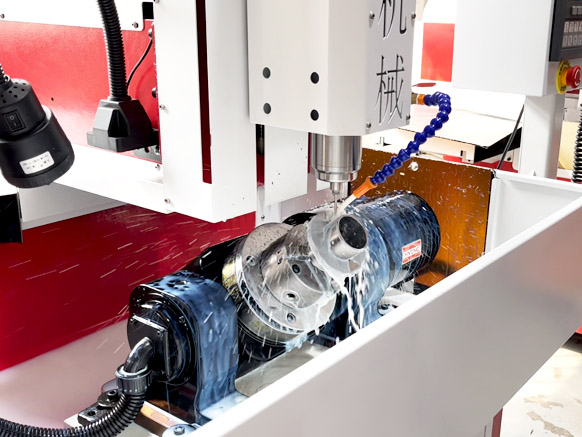

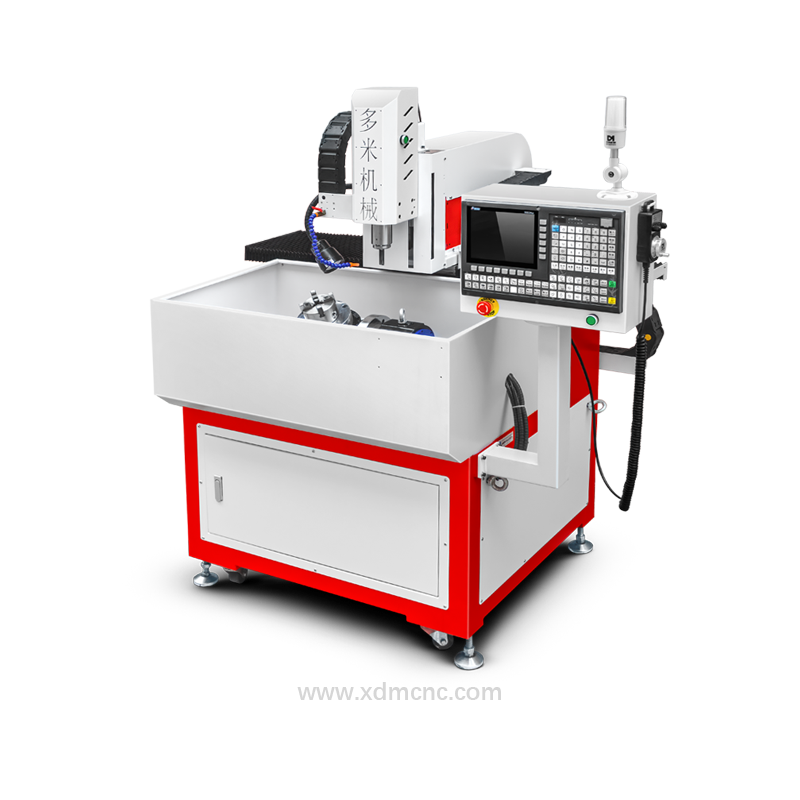

CNC Drilling & Tapping Machine

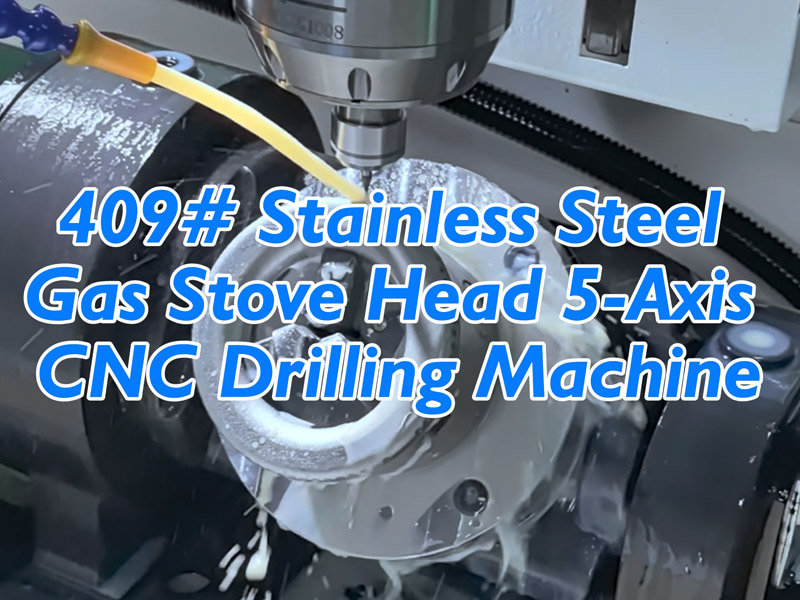

Model: DNC-640(five-axis)

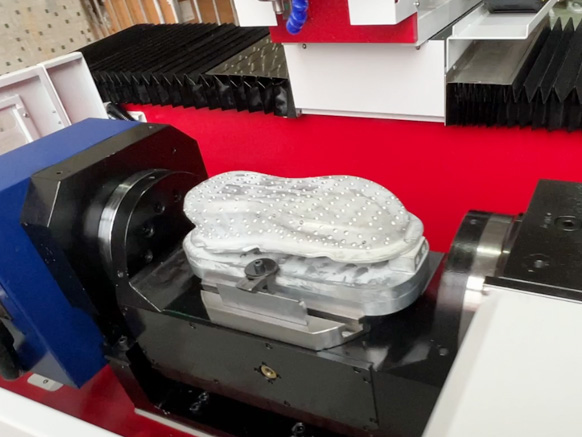

Function: 3D Curved Surface CNC Drilling and Tapping

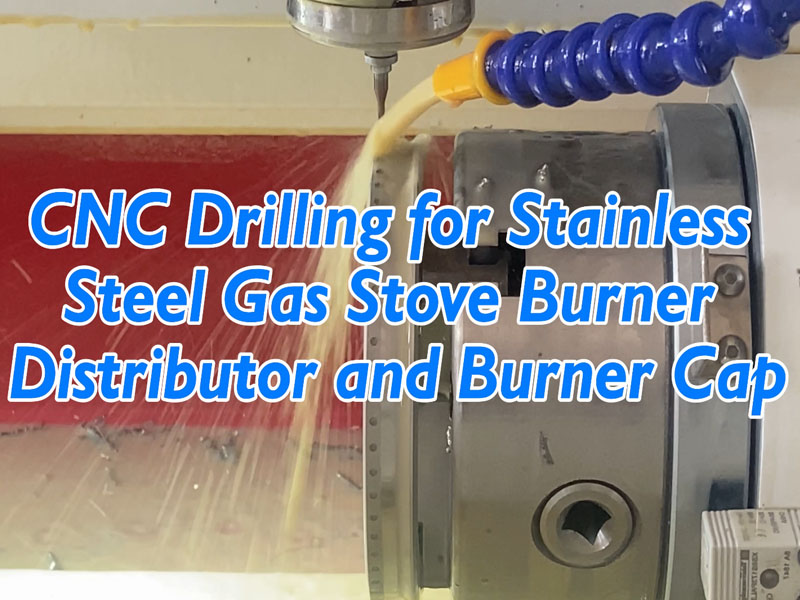

Application Materials: Iron, low carbon steel, stainless steel, titanium, aluminum, copper, red copper, brass , aluminum alloy, Ceramic, etc.

Feature

Gas Stove Burner Cap Drilling Machine

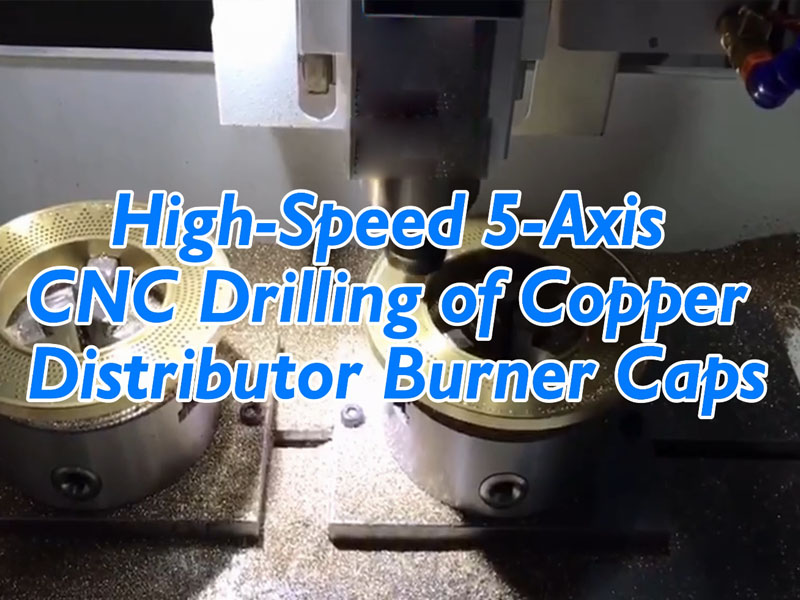

This model is a multi-functional five-axis drilling and tapping equipment.

With four-axis and five-axis rotary platform, it can process 3D curved multi-angle products.

The rotary shaft adopts servo motor with high-precision harmonic reducer, which has high rotation positioning accuracy.

The machine tool comes with a row tool magazine to solve the problem of multiple aperture machining of one product.and the tool change method is simple and stable.

Exquisite and small, less space, one employee can operate multiple equipment at the same time.

Lead time (days) : 7 to 10 working days. (Standard Configuration)

Tip: Our CNC drilling and tapping machines support custom non-standard designs, machine color customization, and OEM branding. Start now to purchase and customize your own equipment, please contact us.

Request A Quote

Request A Quote