CNC (Computer Numerical Control) drilling machines have revolutionized the manufacturing industry, providing unparalleled precision and efficiency in drilling holes of various sizes. Among the many types of CNC drilling machines, those designed to create small diameter holes stand out due to their specific applications and precision requirements. Small diameter hole CNC drilling machines are crucial for industries such as electronics, aerospace, automotive, and medical devices, where tiny, accurate holes are essential for the functionality of the products.

The Importance of Small Diameter Holes

Small diameter holes are often required for various purposes, including ventilation, fluid passage, component mounting, and electrical connections. These holes can range from a few microns to a few millimeters in diameter and demand high precision to ensure that they fit their intended purpose.

In industries like electronics, micro-holes are necessary for the production of circuit boards, where the holes serve as vias for electrical components. In the medical industry, such holes are essential for devices like catheters and surgical tools. Similarly, in aerospace and automotive applications, small diameter holes are required for components such as fuel injectors, hydraulic valves, and fuel filtration systems.

Key Features of Small Diameter Hole CNC Drilling Machines

Precision and Accuracy

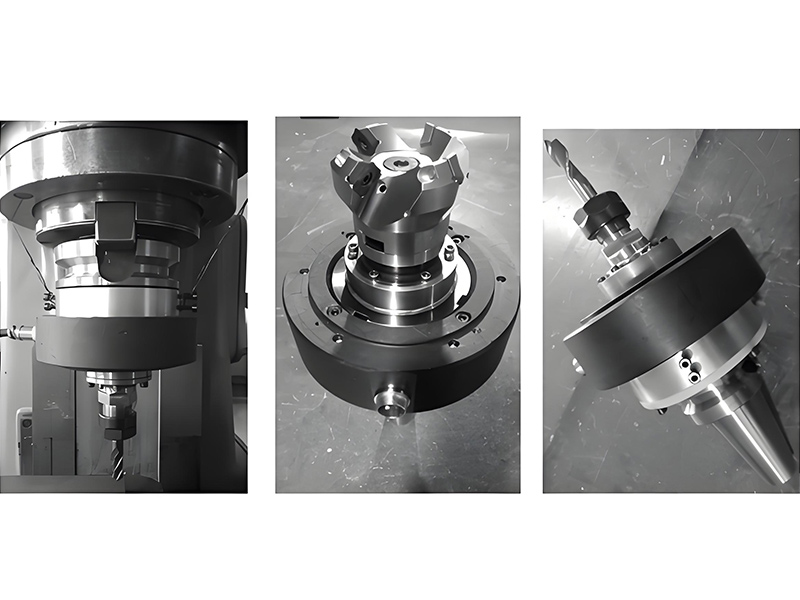

The primary characteristic of small diameter hole CNC drilling machines is their ability to drill holes with extreme precision. These machines employ advanced technologies like fine feed rates, controlled spindle speeds, and high-precision tooling. The machines often feature multiple axis movements, including 3-axis, 4-axis, or even 5-axis capabilities, which enable them to work on complex shapes and deliver high accuracy in hole placement.

High-Speed Drilling

To meet the demands of modern production, small diameter hole CNC drilling machines are engineered for high-speed operations. The machines use advanced spindle motors and cutting tools that can rotate at high speeds, reducing drilling time and increasing productivity. High-speed drilling is essential in minimizing the thermal impact on the material, which can distort hole quality.

Advanced Tooling

To drill tiny holes accurately, these machines often use specialized tools like micro drills, laser drills, or electro-discharge machining (EDM) tools. These tools are designed to handle the intricacies of drilling small diameters, ensuring clean, precise holes without causing damage to the surrounding material.

Material Compatibility

Small diameter CNC drilling machines are capable of working with a variety of materials, from metals like stainless steel and aluminum to plastics, composites, and ceramics. The versatility of these machines allows them to be used in diverse industries and applications. The ability to drill small holes in hard-to-machine materials is a critical feature that makes these machines so valuable.

Applications of Small Diameter Hole CNC Drilling Machines

Electronics and Semiconductor Manufacturing

In the electronics industry, the need for precision is paramount. Small diameter holes are used to create vias in printed circuit boards (PCBs), which connect different layers of the circuit. These holes must be drilled with extreme precision to ensure proper electrical connectivity. CNC drilling machines used in electronics often include laser and mechanical drilling capabilities, allowing manufacturers to meet tight tolerances.

Medical Devices

The medical industry often requires drilling of extremely small and precise holes for devices like stents, needles, catheters, and micro-surgical instruments. Small diameter hole CNC drilling machines are critical in producing these high-precision medical components. These machines must adhere to stringent regulatory standards, ensuring that the holes meet specific tolerances and material integrity.

Aerospace and Automotive

Small diameter holes are also used in the aerospace and automotive industries for fuel injectors, hydraulic systems, air conditioning components, and more. In these fields, drilling with precision is vital for ensuring that the components operate correctly under extreme conditions. CNC drilling machines designed for small diameters are often employed to meet the rigorous requirements of these industries.

Tooling and Molds

Manufacturers of molds, dies, and tooling also rely on small diameter hole CNC drilling machines for drilling cooling holes, ejector pin holes, and other critical features in the tooling process. Precision in these holes is essential for the molding process, affecting the quality of the final product and the efficiency of production.

Challenges and Innovations

While small diameter hole drilling is a vital process, it does present some challenges. The smaller the hole, the more susceptible it is to defects like burrs, tapering, or uneven finishes. Additionally, the material being drilled can affect the quality of the hole, as hard materials or materials with irregular surfaces may cause tool wear or even damage.

To address these challenges, machine manufacturers continuously innovate. New developments in coating technology for cutting tools, improved coolant delivery systems, and more advanced CNC control systems all contribute to overcoming these obstacles. Innovations like laser drilling and EDM technology also provide solutions for drilling extremely small holes with minimal material distortion.

Conclusion

Small diameter hole CNC drilling machines play an indispensable role in a wide array of industries where precision and accuracy are non-negotiable. The ability to drill holes with tight tolerances in a variety of materials opens up countless possibilities in electronics, aerospace, automotive, medical devices, and more. As technology advances, these machines will continue to evolve, delivering even more precision, speed, and versatility for the most demanding applications.