This model is suitable for drilling, tapping and chamfering processing of various flat products.

3-axis CNC machining center numerical control system provides stable performance and easy operation.

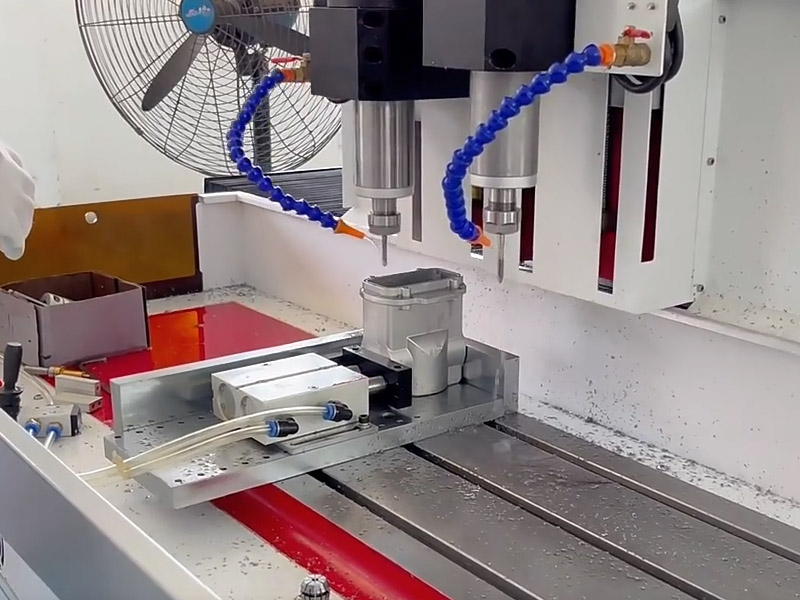

Dual spindle independent servo control, drilling and tapping is completed at one time.

The machine tool adopts moving beam structure, and the open structure of the workbench is suitable for clamping multiple products at the same time, or multi-station processing of a single product.

When it comes to modern metalworking, nothing saves more time and cuts costs better than an Automatic Drilling and Tapping Machine. Instead of doing everything by hand—setting up, drilling holes, switching tools, then tapping threads—this type of machine does it all in one go. It's designed to handle repetitive work with high accuracy, which is why it's become a favorite in shops that deal with large production runs. The best part is that operators don't have to babysit the process. You set up the program, feed the material, and the machine handles drilling and tapping automatically. This reduces errors, improves consistency, and speeds up delivery times.

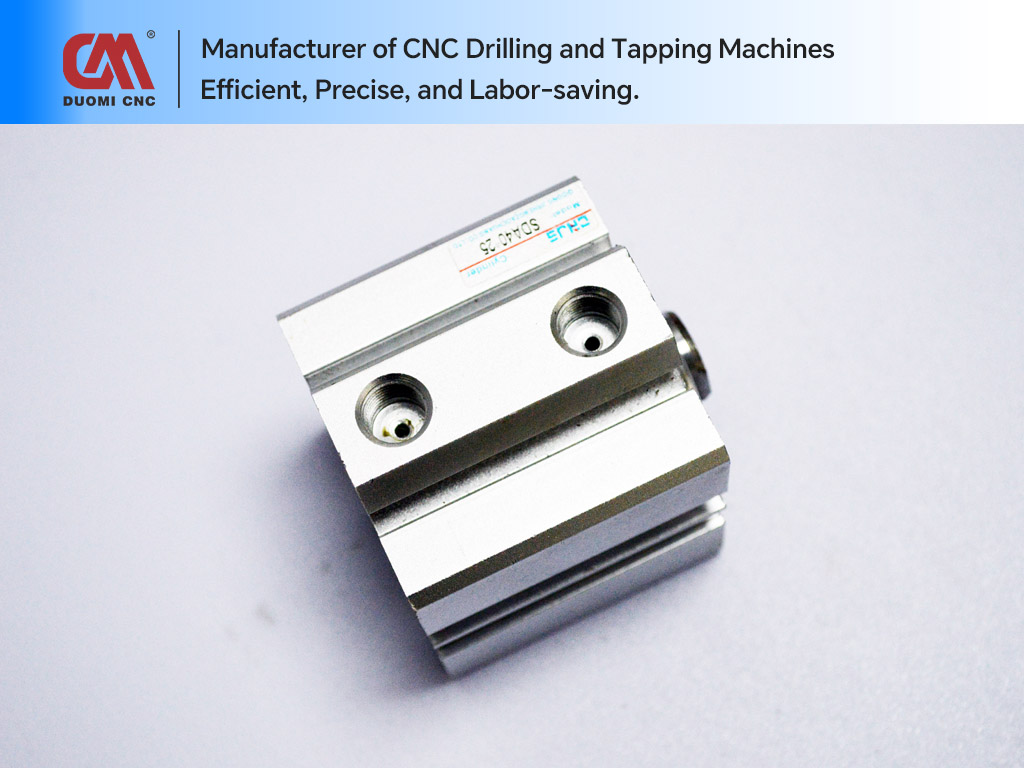

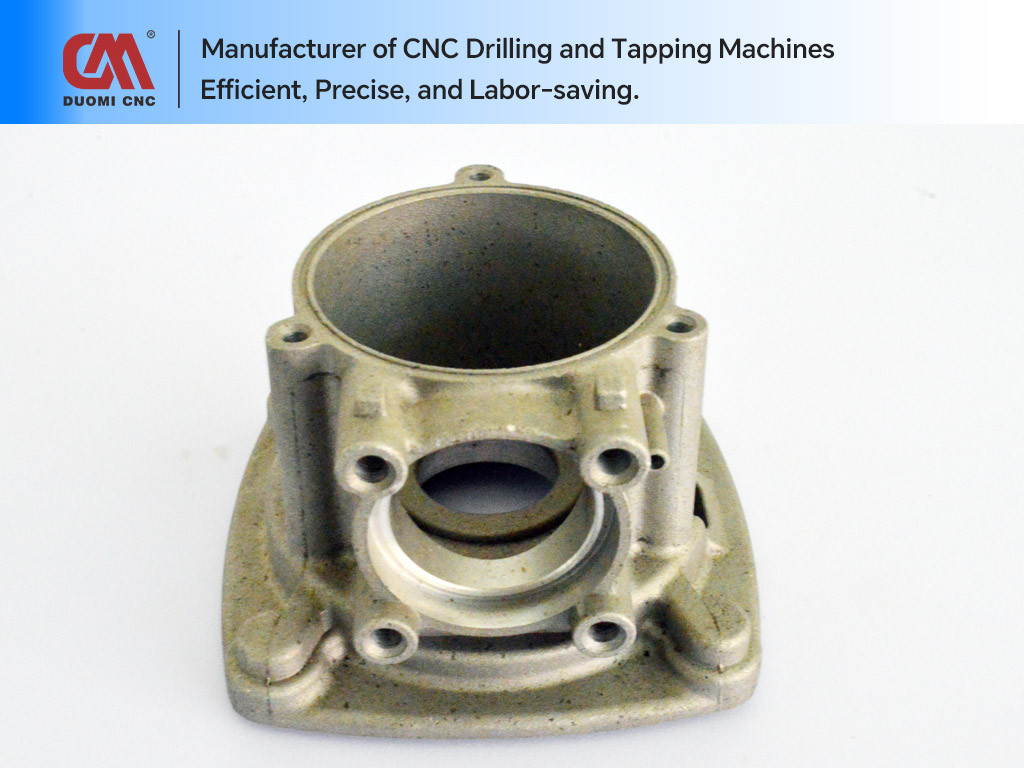

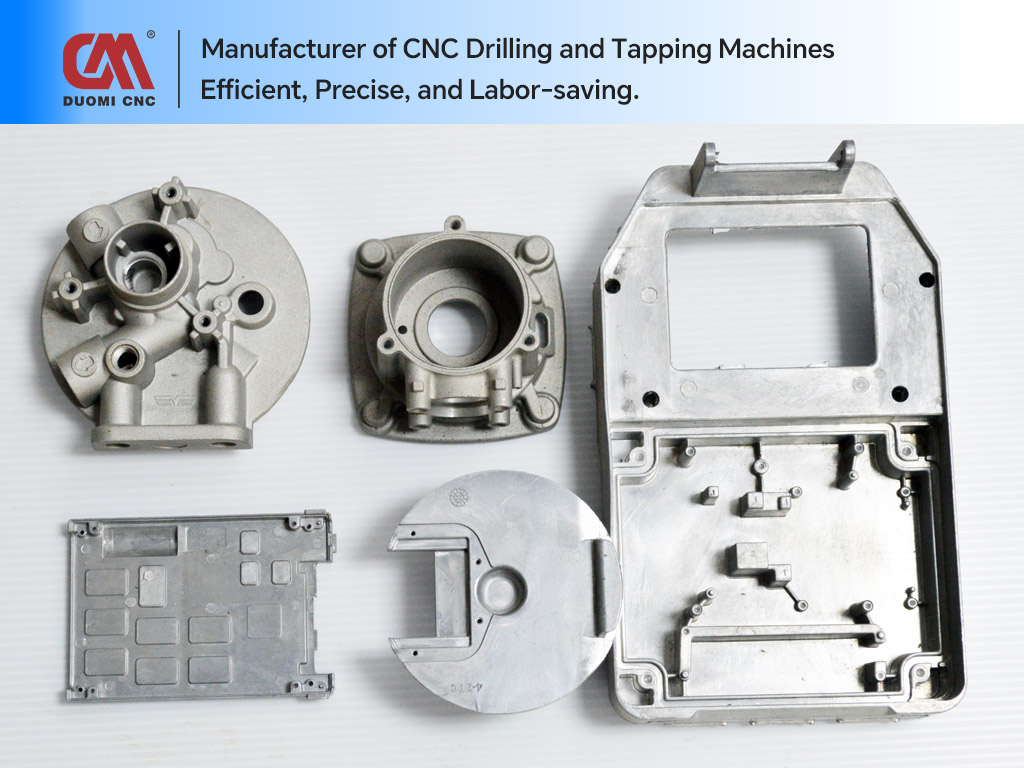

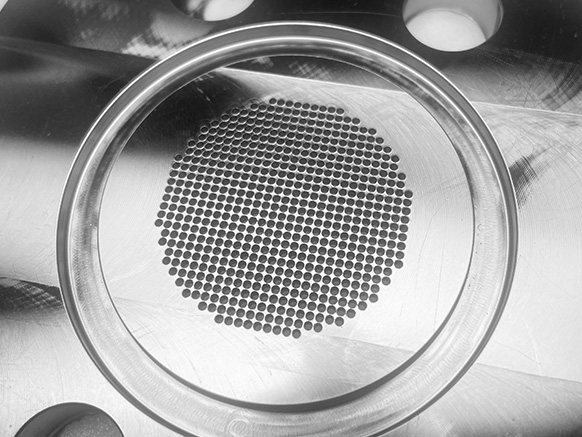

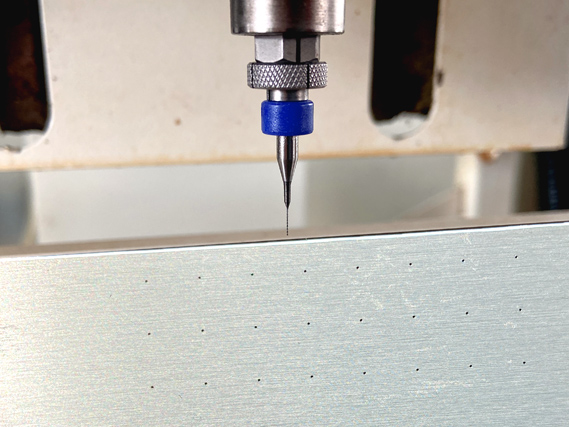

Now, if you step up to a CNC Drilling and Tapping Machine, you get an even higher level of precision and flexibility. CNC control means every hole and every thread is positioned exactly where it should be, with tolerances down to fractions of a millimeter. Shops working with die-cast aluminum housings, engine blocks, and aluminum shells love these machines because aluminum can be tricky—it requires the right speeds and feeds. CNC systems take care of those details, allowing you to process hundreds or even thousands of identical parts without deviation.

One of the best success stories comes from a customer in the automotive sector. They needed to drill and tap multiple holes into die-cast aluminum engine housings. Before switching to CNC, their team relied on manual drilling setups, which were slow and inconsistent. After installing a DUOMI CNC Drilling and Tapping Machine, production efficiency jumped by 40%, and scrap rates dropped to nearly zero. Another client in the electronics industry used an automatic machine for aluminum shells and small housings. They were able to double their throughput, meeting tight deadlines without hiring extra workers.

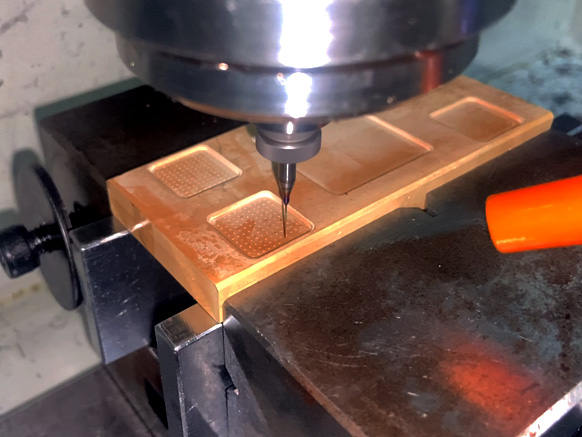

These machines aren't just for aluminum. Customers in general metalworking—working with stainless steel plates, copper connectors, or mild steel components—have seen the same results. The automatic drilling and tapping process eliminates downtime, while CNC control ensures clean threads and accurate positioning, even in tougher materials.

For shops looking to scale up, both the Automatic Drilling and Tapping Machine and the CNC Drilling and Tapping Machine are smart investments. They cut labor costs, reduce rework, and open doors to larger contracts where precision and speed are non-negotiable. DUOMI CNC has been supporting clients across different industries with reliable machines that pay for themselves fast. Whether you're making die-cast aluminum parts, copper busbars, or custom steel components, the results speak for themselves: higher productivity, better quality, and happier customers.

Applications:

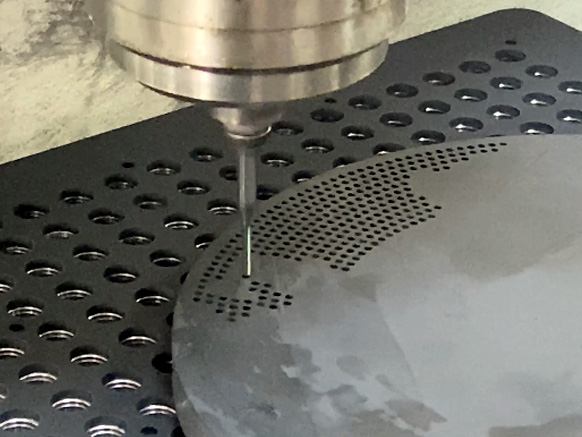

Heat exchanger and condenser tube sheet processing

Structural steel component manufacturing

Automotive, aerospace, and heavy machinery parts

Custom fabrication shops requiring high-throughput drilling precision

Why Choose Us?

As a professional CNC drilling and tapping machine manufacturer, we don't just sell equipment — we deliver tailored drilling solutions. From pre-sale consultation to after-sales technical support, our expert team ensures each machine is aligned with your unique production goals. All machines undergo strict quality control and can be customized for your specific hole sizes, workpiece materials, and automation levels.

Request a Quote Today

Looking to upgrade your production line with a high-speed CNC drilling and tapping machine? Get in touch now to receive a free consultation and competitive quotation. Our technical team is ready to assist you with personalized recommendations and ROI analysis.

✅ Global Delivery Available

✅ OEM & ODM Support

✅ Free Drilling Samples & Video Demonstration

Request A Quote

Request A Quote