2025 High-Precision CNC Drill-Mill Machine with ATC – DUOMI CNC

If you've ever stood in front of a slow, noisy drilling machine… watching the minutes tick by while tools are changed by hand… and praying the next hole will be within tolerance—you know the frustration.

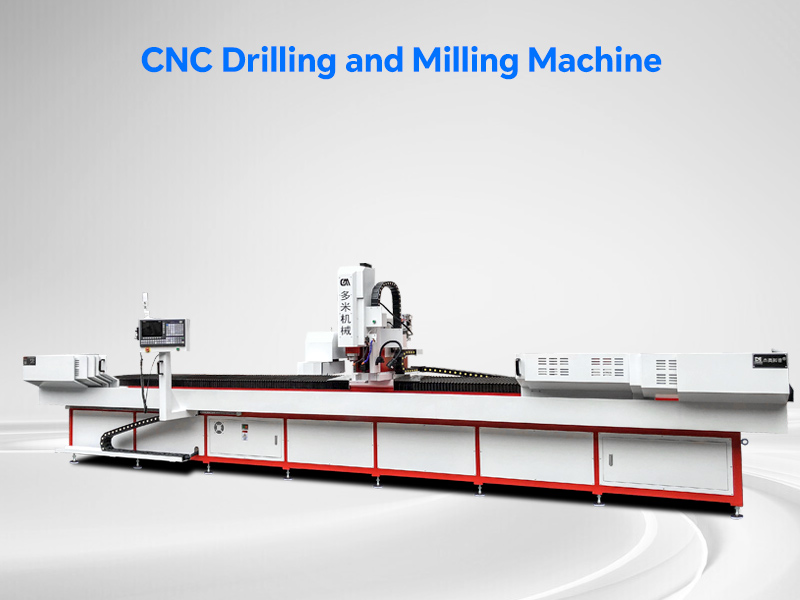

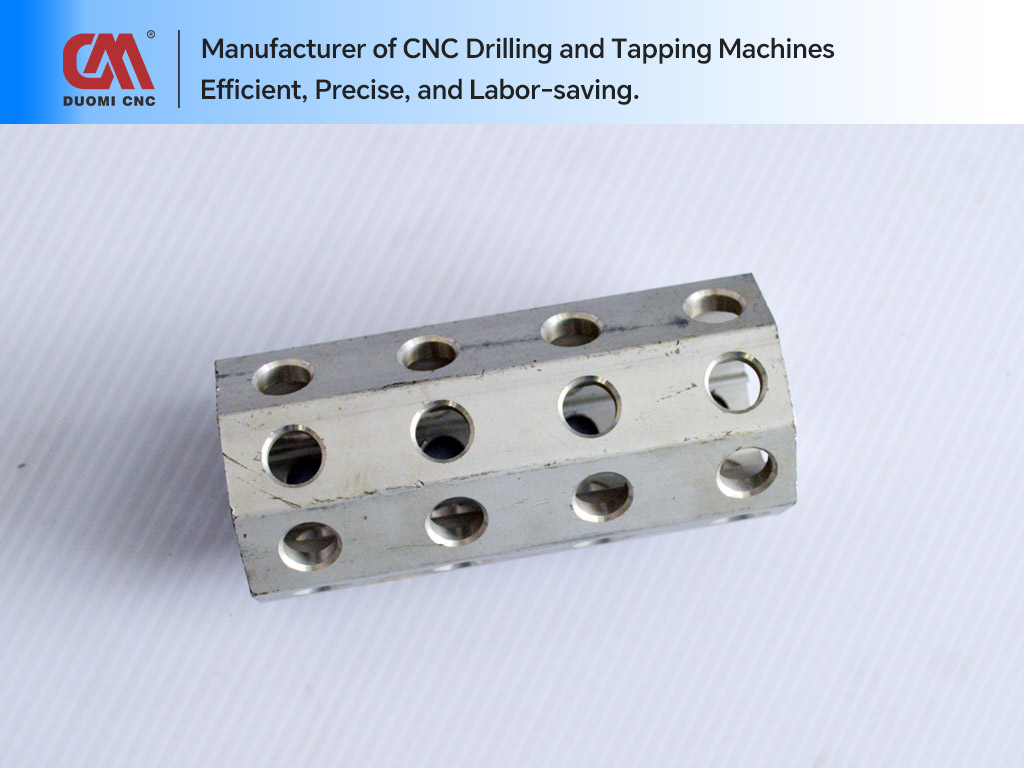

CNC Drilling and Milling Machine

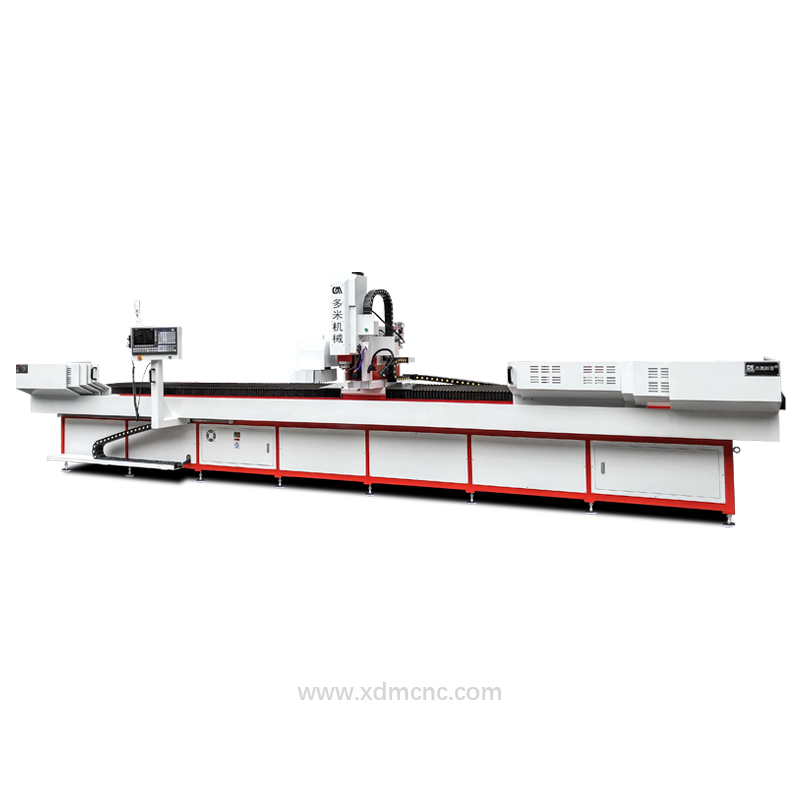

Now imagine a machine that drills, taps, and mills in one go, changes tools in seconds, and delivers perfect holes every single time—whether you're working on steel beams, aluminum profiles, or thick-walled round tubes. That's what the DUOMI CNC High-Precision Drill-Mill Machine with ATC is built to do.

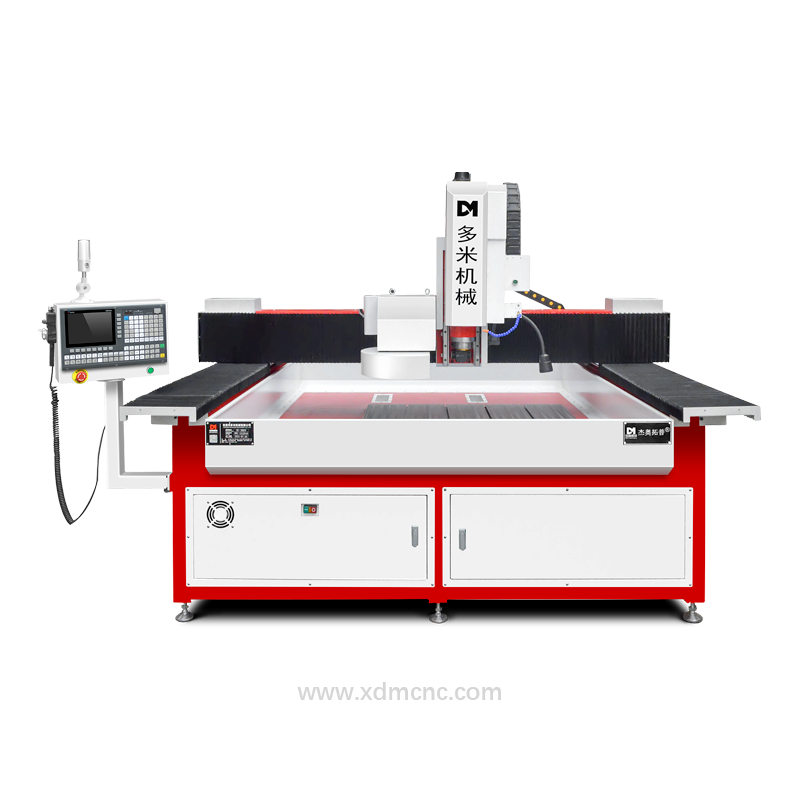

What Makes This CNC Drill-Mill Machine Different?

You don't need another “just okay” machine. You need something that's faster, smarter, and more precise—because every minute of downtime costs money.

Tool Changes in Seconds

No more walking over, unbolting a tool, and losing your production rhythm. The Automatic Tool Changer (ATC) swaps tools instantly, so you can go from drilling to tapping to milling without missing a beat.

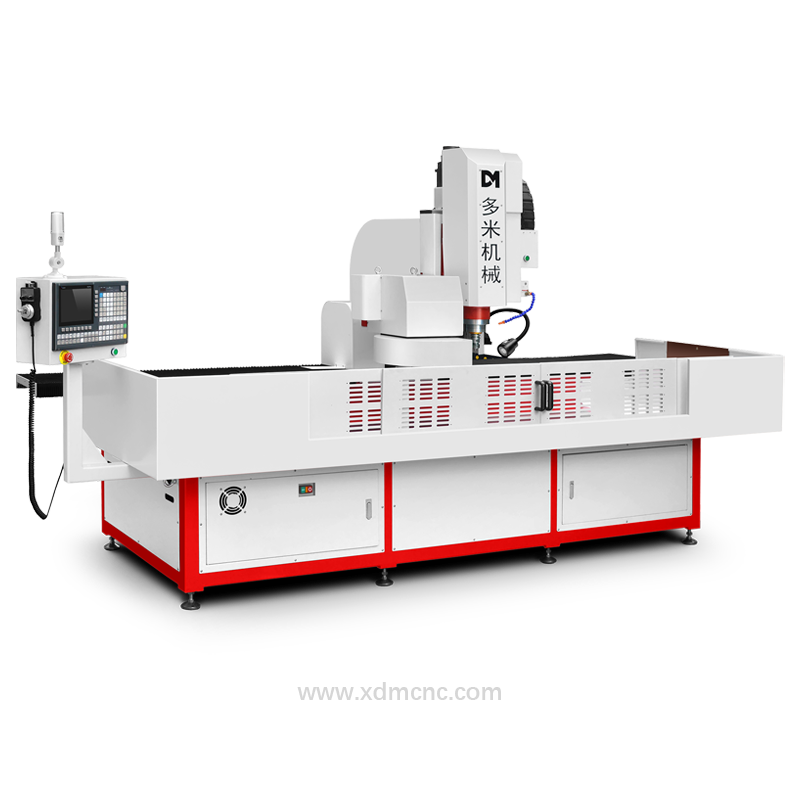

Designed for Heavy-Duty Metal Work

We're talking long steel H-beams, thick stainless tubes, large aluminum profiles—no vibration, no chatter, just clean, accurate cuts.

Small Holes? No Problem

Tiny holes on metal can be a nightmare with older machines. This system is engineered for micro-hole precision, so you can run small-diameter drills without fear of breakage or misalignment.

The Real Pain Points of Traditional Drilling

If this sounds familiar, it's time to upgrade:

Tool changes take forever, slowing your output.

Hole sizes are inconsistent, forcing rework and wasting material.

One machine can't do it all—you're constantly moving parts between stations.

Setup takes too long, especially for complex jobs.

The DUOMI CNC Drill-Mill Machine with ATC removes all of these bottlenecks.

Features That Save You Time and Money

Automatic Tool Changer – change tools in seconds

High-precision ball screw drive – ±0.001 mm tolerance

Heavy-duty frame – stable even with oversized workpieces

Dual high-torque spindles – option for simultaneous operations

User-friendly CNC control – quick programming, easy learning curve

What Customers Are Saying

“Before DUOMI, changing tools took forever, and our micro-hole jobs were always a headache. Now, one operator can run the whole process—from drilling to tapping—without stopping. We've cut production time by 40%.”

— Jason M., Texas, USA

Shipping & Support

Ports of Shipment: Shanghai, Shenzhen, Qingdao, Guangzhou, or your designated port

Warranty: 12-month full coverage, lifetime technical support

Service: Remote troubleshooting, spare parts supply, on-site training if needed

Ready to See the Difference?

If your shop is still stuck with slow, outdated drilling setups, now's the time to switch. The 2025 DUOMI CNC High-Precision Drill-Mill Machine with ATC gives you speed, accuracy, and flexibility in one system.

Get your free quote and test cut sample today