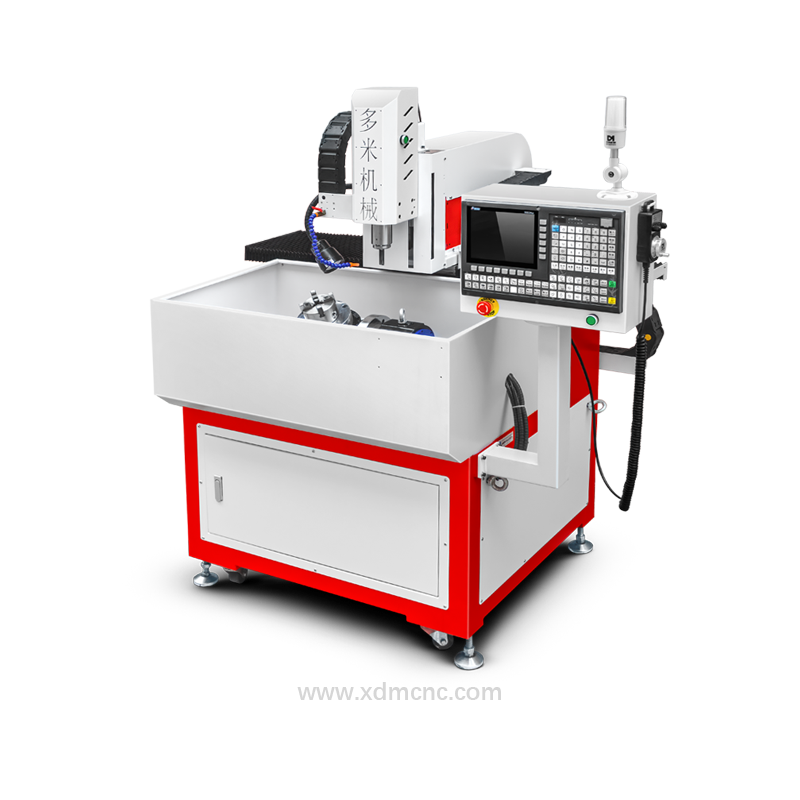

In modern manufacturing, precision and efficiency are crucial for producing high-performance mechanical components. Gears and bearings, essential elements in automotive, aerospace, and industrial machinery, require precise lubrication hole drilling to ensure smooth operation and longevity. The Five-Axis CNC Drilling Machine for Gear and Bearing Lubrication Holes is an advanced solution that enhances machining accuracy, reduces production time, and optimizes lubrication efficiency.

Features of the Five-Axis CNC Drilling Machine

High Precision Drilling: The machine is equipped with a five-axis system that enables multi-directional drilling with micron-level accuracy. This ensures that lubrication holes are placed at optimal locations for maximum efficiency.

Automated Operation: With an advanced CNC control system, the drilling process is fully automated, reducing human error and improving consistency in production.

Adaptive Cutting Technology: The machine adapts to different material types, including hardened steel, stainless steel, and titanium, using high-speed spindles and specialized cutting tools.

Real-Time Monitoring: Integrated sensors and software provide real-time feedback, allowing for adjustments in drilling speed, feed rate, and spindle rotation to maintain precision.

Energy Efficiency: The machine is designed to minimize power consumption while maintaining high-speed operations, making it an eco-friendly solution for manufacturers.

Benefits of Using a Five-Axis CNC Drilling Machine for Lubrication Holes

Enhanced Durability: Properly positioned lubrication holes improve the performance and lifespan of gears and bearings by reducing friction and wear.

Improved Manufacturing Efficiency: The five-axis capability eliminates the need for multiple setups, significantly reducing production time and labor costs.

Versatility in Application: Suitable for various industries, including automotive, aerospace, wind energy, and heavy machinery manufacturing.

Superior Surface Finish: The high-speed drilling process produces smooth and burr-free holes, eliminating the need for additional finishing operations.

Applications of the Five-Axis CNC Drilling Machine

Automotive Industry: Ensures precise lubrication holes in transmission gears and wheel bearings, reducing maintenance costs.

Aerospace Sector: Used for drilling lubrication holes in jet engine components, enhancing fuel efficiency and operational reliability.

Industrial Machinery: Improves the performance of heavy-duty mechanical systems in manufacturing plants.

Wind Energy Sector: Enhances the efficiency of wind turbine gearboxes by optimizing lubrication distribution.

Conclusion

The Five-Axis CNC Drilling Machine for Gear and Bearing Lubrication Holes is a game-changer for industries requiring precise and efficient machining solutions. Its advanced technology ensures high-precision drilling, reduced production time, and enhanced component durability. As industries continue to demand higher performance and reliability, investing in a five-axis CNC drilling machine is a strategic move for manufacturers seeking to stay competitive in the global market.