CNC drilling machines for long steel plates have become an essential tool in modern industries, offering precision, efficiency, and automation. These machines are widely used in various sectors, including construction, shipbuilding, bridge manufacturing, and heavy machinery production. By automating the drilling process, CNC drilling machines enhance productivity, reduce labor costs, and ensure high-quality output. This article explores the applications, advantages, and impact of CNC drilling machines for long steel plates.

1. Overview of CNC Drilling Machines for Long Steel Plates

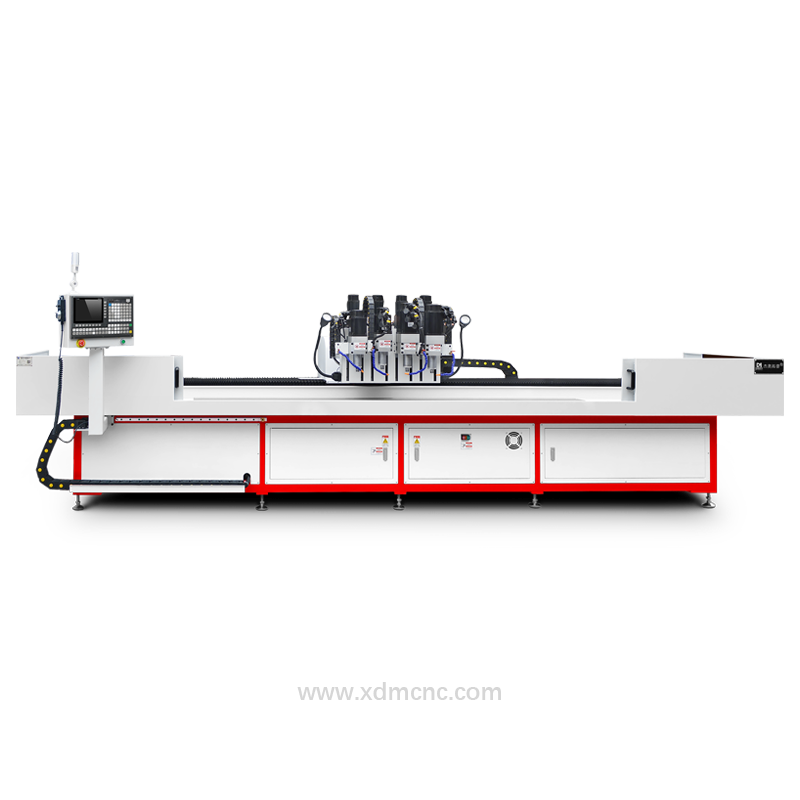

CNC (Computer Numerical Control) drilling machines are designed to perform high-precision drilling operations on long steel plates. These machines use automated programming to execute drilling tasks with minimal human intervention. Equipped with advanced sensors and servo motors, they can process large workpieces efficiently and accurately.

2. Key Applications

2.1 Construction Industry

In the construction industry, long steel plates are essential for building structures such as bridges, skyscrapers, and industrial facilities. CNC drilling machines are used to create bolt holes and fastening points with high precision. This ensures proper alignment and structural integrity, reducing assembly errors and improving safety.

2.2 Shipbuilding Industry

Shipbuilding requires extensive drilling operations on large steel plates used for hulls, decks, and bulkheads. CNC drilling machines streamline this process by offering consistent accuracy and reducing manual labor. These machines support the production of complex marine structures with minimal errors, leading to higher efficiency and reduced production costs.

2.3 Bridge Manufacturing

Long steel plates are a primary component in bridge construction, where precise drilling is necessary for assembling girders and beams. CNC drilling machines allow for the rapid and accurate preparation of steel plates, ensuring durability and stability in bridge structures.

2.4 Heavy Machinery and Equipment Manufacturing

Manufacturers of heavy machinery, such as cranes, excavators, and industrial processing equipment, rely on CNC drilling machines to produce high-strength steel components. The ability to drill precise holes in thick steel plates enhances the overall performance and durability of these machines.

2.5 Wind Energy Sector

The renewable energy industry, particularly wind energy, relies on CNC drilling machines for fabricating large steel components used in wind turbines. The precision drilling process ensures proper alignment and assembly, contributing to the reliability and longevity of wind energy systems.

3. Advantages of CNC Drilling Machines for Long Steel Plates

3.1 High Precision

CNC drilling machines offer exceptional accuracy, reducing errors and minimizing material wastage. This ensures that steel plates meet exact specifications for assembly and structural integrity.

3.2 Increased Efficiency

Automated drilling significantly improves processing speed, enabling manufacturers to complete large-scale projects in shorter time frames. This is particularly beneficial for industries with high production demands.

3.3 Cost Reduction

By reducing manual labor and minimizing errors, CNC drilling machines lower operational costs. The increased efficiency and reduced material waste further contribute to cost savings.

3.4 Versatility

These machines can handle various steel plate thicknesses and dimensions, making them suitable for a wide range of applications across different industries.

3.5 Enhanced Safety

Automation reduces the need for manual handling, lowering the risk of workplace accidents. Operators can monitor the process from a safe distance, improving overall safety standards.

4. Future Trends and Innovations

As technology advances, CNC drilling machines continue to evolve with improved automation, AI integration, and real-time monitoring capabilities. The use of smart sensors and IoT technology is expected to enhance efficiency and predictive maintenance, reducing downtime and increasing productivity.

CNC drilling machines for long steel plates play a crucial role in various industries, offering precision, efficiency, and cost-effectiveness. Their applications in construction, shipbuilding, bridge manufacturing, and heavy machinery production highlight their importance in modern manufacturing. As technology progresses, these machines will continue to revolutionize the steel processing industry, driving innovation and enhancing industrial productivity.