In today's fast-paced manufacturing world, precision and speed are key. CNC drilling and tapping machines are transforming how industries like automotive, furniture, and fitness equipment process metal components.

Unlike manual drilling, CNC drilling and tapping machines use automated control systems to ensure every hole is drilled with millimeter precision. Whether you're working on aluminum profiles, steel square tubes, or stainless components, these machines offer consistent accuracy with minimal errors.

One of the top benefits is increased productivity. CNC machines can run 24/7 with minimal human supervision, dramatically reducing downtime. With multi-axis control and servo motors, operators can complete complex drilling and tapping operations in a single setup.

Another critical advantage is cost efficiency. By reducing material waste and labor costs, CNC drilling and tapping machines offer a fast return on investment for manufacturers.

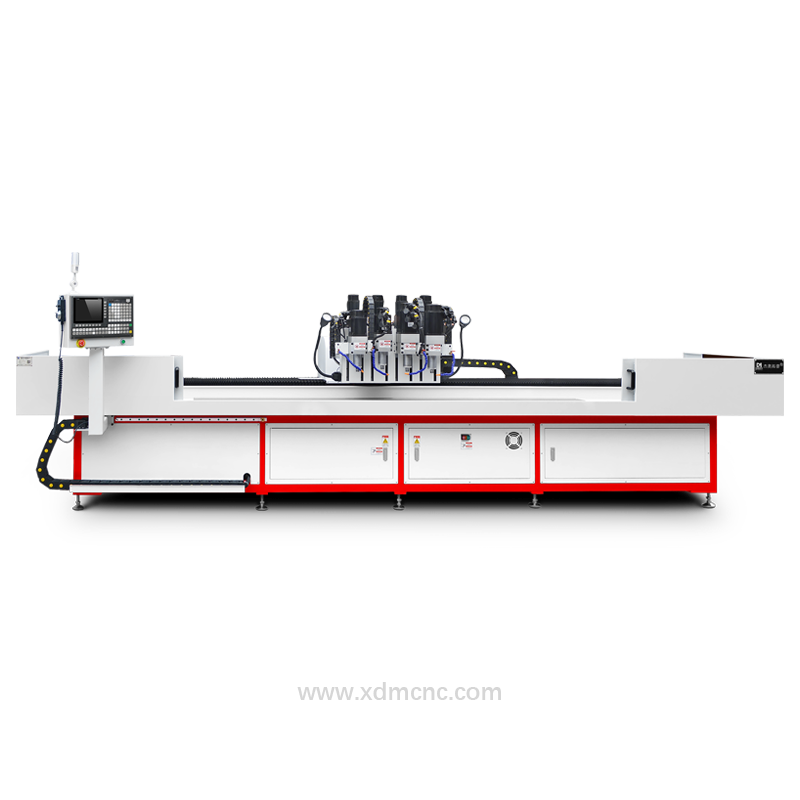

DUOMI CNC is a trusted name in this field, offering advanced machines tailored for various applications—from small-diameter holes to high-speed mass production. Our solutions support smart manufacturing upgrades and help global clients stay competitive.

Keywords: CNC drilling and tapping, CNC tapping machine, DUOMI CNC, metal processing, automatic drilling