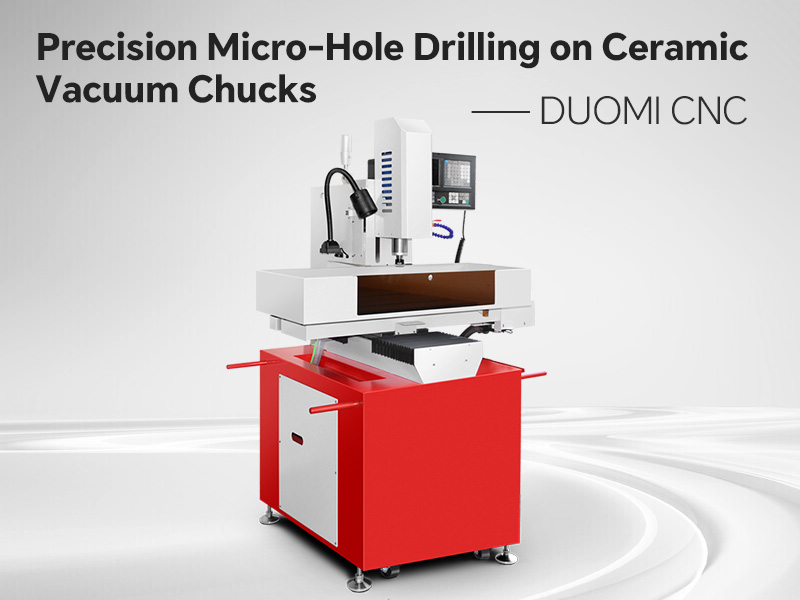

This equipment is specifically designed for micro-drilling on ceramic suction plates, utilizing high-precision CNC control. It is widely used in industries such as semiconductors, optics, and electronics manufacturing. The equipment features the following advantages:

High-Precision Drilling

Utilizing ultra-hard carbide drill bits or laser micro-machining technology, it can process micro-holes as small as 50μm, ensuring high accuracy and consistency.

CNC Intelligent Control

Equipped with a multi-axis CNC system, supporting high-precision positioning and batch processing, ensuring processing stability and efficiency.

Efficient Dust Removal System

Features a vacuum adsorption and nano-level dust removal system, reducing dust pollution and improving hole quality and cleanliness of the working environment.

Wide Range of Materials

Suitable for processing alumina ceramics, silicon nitride ceramics, silicon carbide ceramics, and other high-hardness materials, meeting diverse industrial demands.

Customized Processing

Capable of adjusting hole diameter, hole spacing, and suction surface structure according to customer requirements, providing tailored solutions.

This equipment is widely used in semiconductor manufacturing, vacuum adsorption systems, and precision filtration components, making it an ideal choice for high-end precision manufacturing.