The Square Steel Thermal Drilling and Tapping Machine effectively addresses several pain points in metal processing:

1. Limitations of Traditional Drilling Methods

Pain Point: Conventional drilling methods (e.g., twist drills) often create shallow-threaded holes in thin-walled square steel, leading to weak connections and thread stripping.

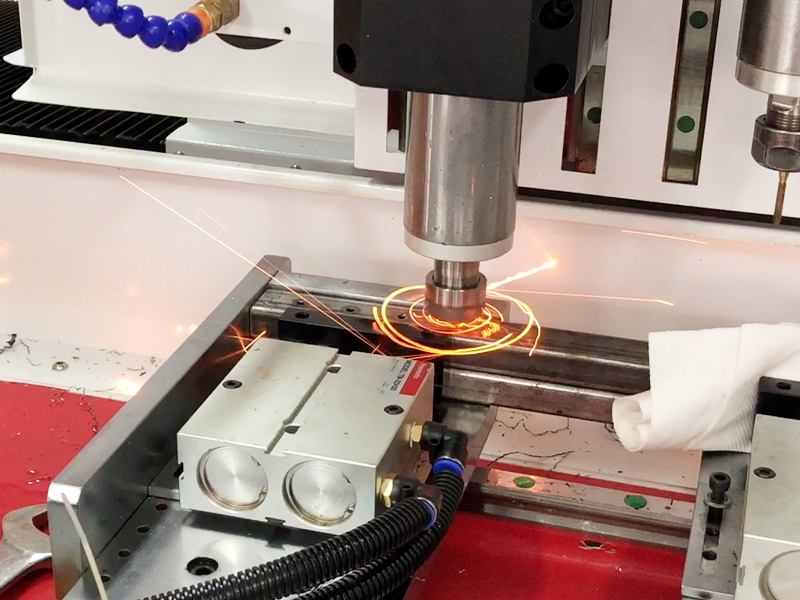

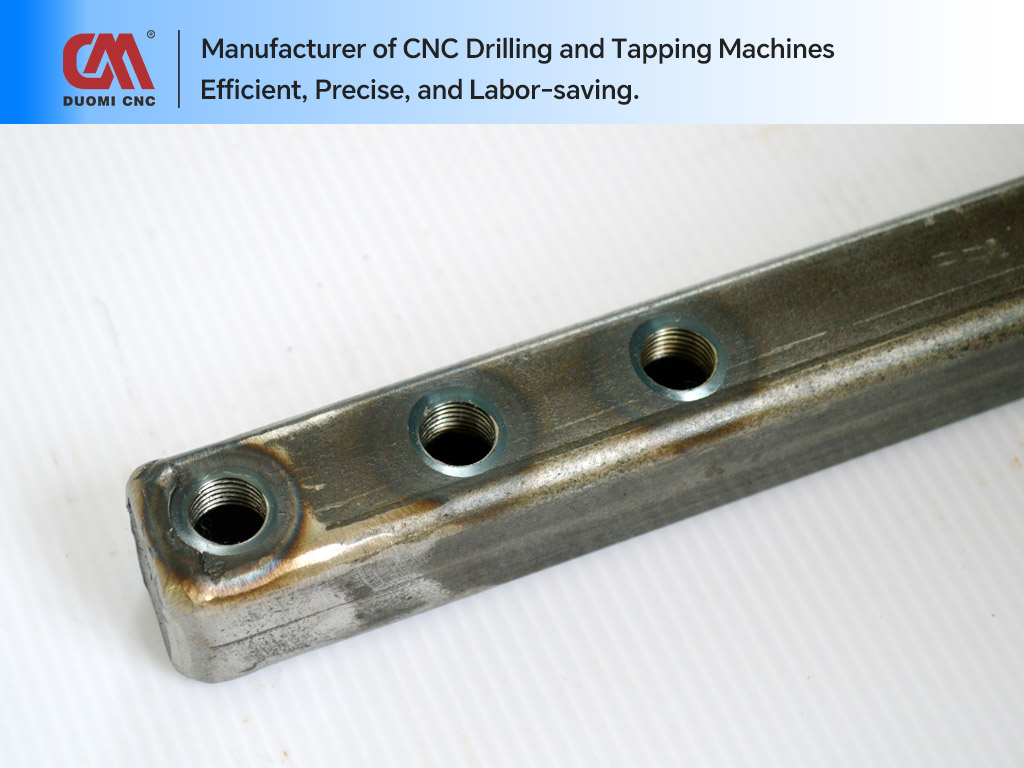

Solution: Thermal drilling generates heat through high-speed friction, allowing metal to plastically deform and form an extended hole wall, which increases thread depth and enhances connection strength.

2. Dependency on Additional Accessories

Pain Point: Traditional tapping in thin-walled metal often requires additional welded or rivet nuts to reinforce the thread, increasing costs and complexity.

Solution: With thermal drilling and tapping, holes and threads are formed in one process, eliminating the need for extra nuts and reducing material costs.

3. Complex Process and Low Efficiency

Pain Point: The conventional process involves drilling, reaming, tapping, or welding nuts, requiring multiple steps, increasing labor time and cost.

Solution: The thermal drilling and tapping machine completes drilling and threading in a single operation, streamlining production and boosting efficiency.

4. Issues with Thread Precision and Durability

Pain Point: Traditional tapping in thin-walled square steel produces weak threads with minimal depth, leading to reduced durability and increased failure rates.

Solution: By forming deeper threads through metal displacement, the thermal drilling and tapping process significantly improves thread strength and longevity, reducing maintenance costs.

5. Limited Material Compatibility

Pain Point: Traditional drilling and tapping methods struggle with thin-walled square steel, especially stainless steel and aluminum alloys, causing frequent tool wear and poor processing quality.

Solution: The thermal drilling and tapping machine is compatible with carbon steel, stainless steel, aluminum, copper, and other metals, expanding its usability across industries.

Conclusion

The Square Steel Thermal Drilling and Tapping Machine enhances thread connection strength, reduces reliance on extra components, simplifies processing, increases efficiency, and supports a wider range of materials—making it a game-changer in metal fabrication.