CNC tapping machines have revolutionized the way industries perform threading operations. These advanced machines offer precision, speed, and consistency, making them an essential tool for manufacturers, metalworkers, and machinists. In this article, we will explore the key aspects of tapping CNC machines, their benefits, and the best practices for maximizing efficiency.

1. What is a Tapping CNC Machine?

A tapping CNC machine is a computer-controlled tool used to create internal threads in pre-drilled holes. Unlike manual tapping, CNC tapping automates the process, reducing errors and increasing production efficiency. It is commonly used in industries such as aerospace, automotive, electronics, and metal fabrication.

2. How Does a CNC Tapping Machine Work?

A tapping CNC machine uses a rotating tap tool to cut threads into a material. The machine follows programmed instructions to ensure precise depth and pitch, resulting in highly accurate threads. The process involves:

Hole Preparation – The material is drilled to the required diameter.

Tap Selection – Choosing the right tap size and type for the job.

Tapping Cycle – The CNC machine synchronizes rotation and feed rate to cut threads efficiently.

Lubrication & Cooling – Reduces heat and extends tool life.

Chip Removal – Ensures a smooth, clean threading process.

3. Benefits of Using a CNC Tapping Machine

a) High Precision and Accuracy

CNC tapping eliminates human error and ensures consistent thread depth and pitch, improving the quality of threaded holes.

b) Increased Speed and Productivity

Automating the tapping process reduces cycle times and boosts overall production output.

c) Reduced Tool Wear

Proper feed rates, lubrication, and controlled torque prevent excessive wear, extending tool life and reducing maintenance costs.

d) Versatility

CNC tapping machines can handle various materials, including aluminum, stainless steel, titanium, and plastics.

e) Improved Safety

Manual tapping can lead to tool breakage and workpiece damage. CNC machines minimize these risks by providing controlled and stable operations.

4. Types of CNC Tapping Machines

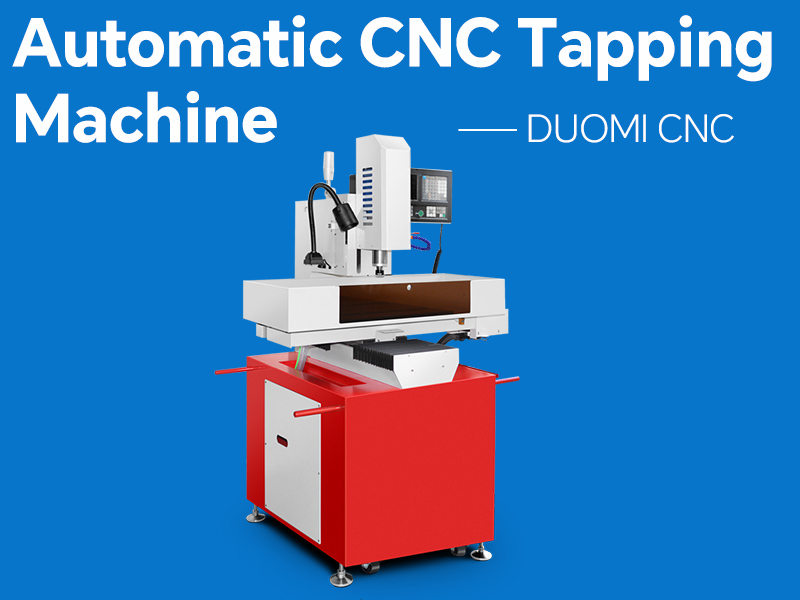

a) Vertical CNC Tapping Machine

Best for drilling and tapping operations in industries like automotive and aerospace.

Offers high precision and stability.

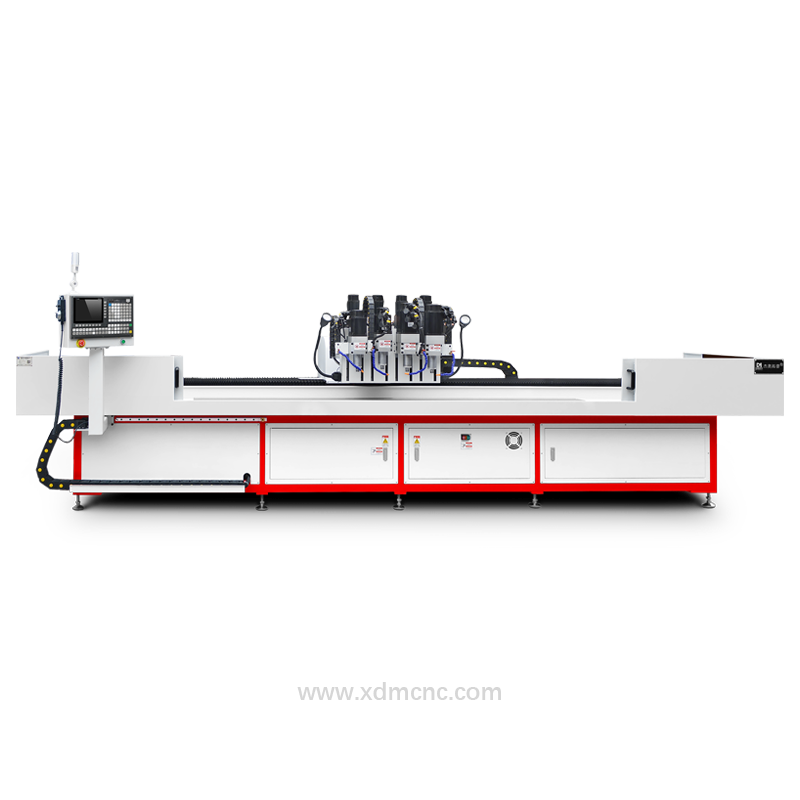

b) Horizontal CNC Tapping Machine

Ideal for large and heavy workpieces.

Commonly used in heavy-duty industrial applications.

c) Multi-Spindle CNC Tapping Machine

Used for mass production.

Simultaneously taps multiple holes, increasing efficiency.

d) Robotic Tapping CNC Machine

Integrated with automation for smart manufacturing.

Suitable for high-speed, precision applications.

5. Best Practices for CNC Tapping

a) Choose the Right Tap Tool

Spiral Point Taps – For through holes.

Spiral Flute Taps – Best for blind holes.

Forming Taps – Ideal for high-strength materials.

b) Use Proper Lubrication

Applying coolant or cutting oil prevents overheating and ensures a smoother tapping process.

c) Optimize Feed Rate and Speed

Using the correct RPM prevents tap breakage and improves thread quality.

d) Regular Maintenance and Calibration

Checking spindle alignment and tool sharpness enhances machine longevity.

6. Applications of CNC Tapping Machines

- Automotive Industry: Producing threaded components for engines, transmissions, and body parts.

- Aerospace Industry: Ensuring precision threading in aircraft structures.

- Electronics Manufacturing: Creating threaded holes in circuit boards and enclosures.

- Medical Device Industry: Producing precision medical implants and instruments.

Conclusion

A tapping CNC machine is an essential tool for modern machining operations, providing precision, efficiency, and reliability. Whether you're working in automotive, aerospace, or metal fabrication, investing in the right CNC tapping machine can enhance productivity and reduce manufacturing costs. By following best practices and maintaining the equipment properly, manufacturers can achieve optimal performance and long-lasting results.

Keywords: CNC tapping machine, best CNC tapping machine, CNC threading, precision tapping, CNC machining, automated threading, industrial tapping machine