CNC (Computer Numerical Control) drilling machines are essential tools in modern manufacturing, offering precision, efficiency, and automation. Whether used for metal, wood, or composite materials, CNC drilling has revolutionized the way industries handle hole-making processes. This article explores the fundamentals of CNC drilling machines, their working principles, and their applications.

What Is a CNC Drilling Machine?

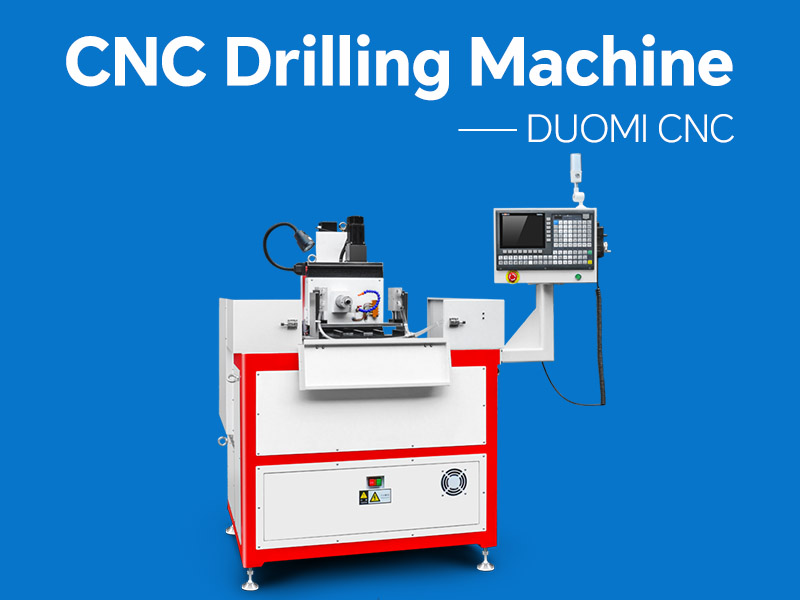

A CNC drilling machine is a computer-controlled tool designed to create precise and consistent holes in a variety of materials. Unlike manual drilling, CNC drilling machines operate with automated programming, reducing human error and increasing production speed. These machines are commonly used in aerospace, automotive, construction, and electronics industries.

How Does a CNC Drilling Machine Work?

CAD Design: The process starts with a CAD (Computer-Aided Design) file that defines hole positions and sizes.

CAM Processing: The CAD file is converted into a CNC program via CAM (Computer-Aided Manufacturing) software.

Material Setup: The workpiece is securely fixed on the machine table.

Tool Selection: The CNC system selects the appropriate drill bit based on the programmed instructions.

Drilling Operation: The spindle rotates the drill bit at high speed while precise movements are controlled by servo motors.

Finishing and Quality Check: Once the drilling is completed, the component undergoes quality inspection.

Advantages of CNC Drilling Machines

High Precision: CNC technology ensures accuracy within microns, reducing material waste.

Automation & Efficiency: Multiple holes can be drilled simultaneously, increasing production speed.

Versatility: Suitable for various materials such as aluminum, steel, plastics, and composites.

Reduced Labor Costs: Minimal operator intervention is required.

Consistent Quality: Eliminates human inconsistencies in hole placement and depth.

Applications of CNC Drilling Machines

Aerospace: Used for drilling rivet and bolt holes in aircraft components.

Automotive: Creates precise mounting holes in engine and chassis parts.

Electronics: Used for circuit board drilling and component assembly.

Construction: Produces structural holes for steel frameworks.

Furniture Making: Drills precise holes for dowels and fasteners in wooden furniture.

Types of CNC Drilling Machines

Vertical CNC Drilling Machines: Best for high-speed drilling with downward force.

Horizontal CNC Drilling Machines: Ideal for deep-hole drilling applications.

Multi-Spindle CNC Drilling Machines: Capable of drilling multiple holes simultaneously.

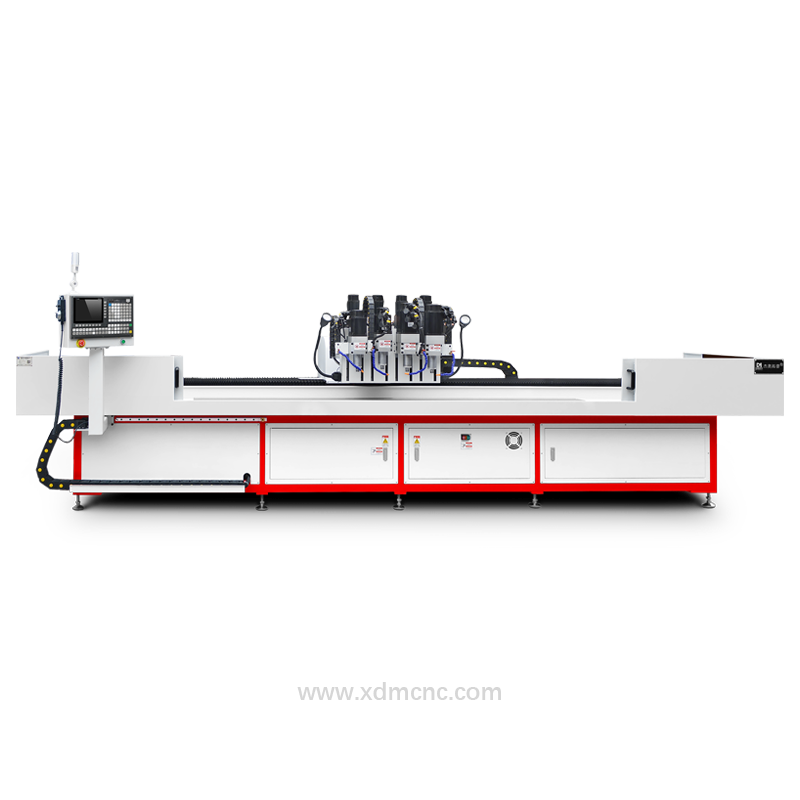

Gantry CNC Drilling Machines: Suitable for large-scale industrial applications.

Choosing the Right CNC Drilling Machine

When selecting a CNC drilling machine, consider the following factors:

Material Compatibility: Ensure the machine is capable of drilling the materials you work with.

Drill Bit Type: Choose a machine that supports various drill bit types (carbide, HSS, coated bits).

Spindle Speed & Power: Higher spindle speeds provide better efficiency for different materials.

Automation Features: Look for machines with tool changers, coolant systems, and automatic calibration.

Software Compatibility: Ensure the machine supports common CAD/CAM software.

Conclusion

CNC drilling machines have become an indispensable part of modern manufacturing, offering precision, efficiency, and automation. Whether you're in aerospace, automotive, or electronics, investing in the right CNC drilling machine can significantly improve production capabilities. As technology advances, these machines will continue to evolve, integrating AI and IoT for smarter and more efficient operations.