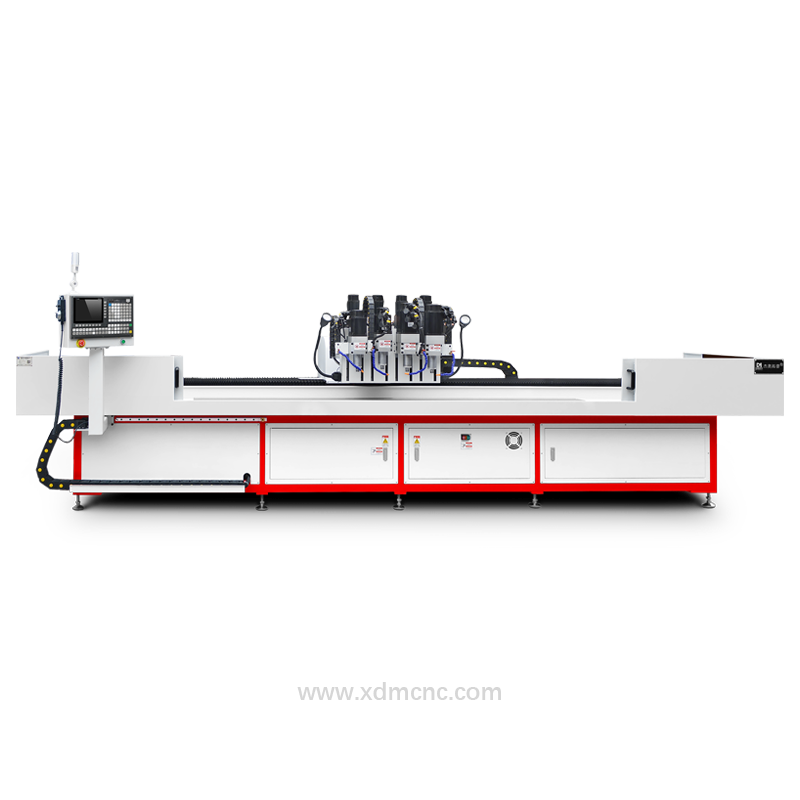

The DUOMI CNC Drilling Machine offers several benefits, making it an excellent choice for precision drilling applications.

Here are the key advantages:

1. High Precision & Accuracy

Utilizes computer numerical control (CNC) for precise drilling.

Ensures consistent hole placement and depth with minimal error.

Suitable for complex and intricate designs.

2. Increased Efficiency & Speed

Automates the drilling process, reducing manual labor.

Handles multiple drilling operations in one setup, improving productivity.

Fast spindle speeds and tool-changing mechanisms speed up production.

3. Versatility & Multi-Functionality

Compatible with various materials like metal, wood, plastic, and composites.

Can perform drilling, tapping, and milling in one machine.

Supports different drill bit sizes and configurations.

4. Cost-Effective & Labor-Saving

Reduces the need for multiple machines or manual adjustments.

Minimizes material waste due to high precision.

Lowers operational costs by improving workflow efficiency.

5. User-Friendly Operation

Equipped with an intuitive CNC control system.

Easy to program and operate with minimal training.

Reduces human errors with automated settings.

6. Durability & Low Maintenance

Built with robust materials and components for long-lasting use.

Requires minimal maintenance compared to manual drilling machines.

Features self-lubricating systems to extend tool life.

7. Customization & Scalability

Can be integrated with automation systems like robot arms or conveyors.

Supports customized drilling patterns for specific industry needs.

Ideal for small-scale workshops and large-scale manufacturing.

One of the reasons the DUOMI is suited for the engineering industry is its capacity. Typically, machining centres have a small bed size, but the DUOMI has a table bed that supports between two to ten metres, so it's perfect for beam work, box sections or plate.

Not only does this machine allow you to drill or light mill longer workpieces but it is surprisingly easy and quick to programme. One of the issues our customers have is of manual marking, which is subject to human error, inaccurate and time-consuming.

The DUOMI can be programmed after just a couple of hours training so you’re up and running almost immediately, for precision, excellent control and fast, efficient production.

If you're rubbing your hands together with glee at having found the perfect drill and mill machine, you’ll be even more pleased to hear that this machine is particularly well priced compared to CNC machining centres.

So, save time, money and drastically improve your automation and workflow with the Bauer DUOMI CNC drill and Mill. Contact us today and get your milling and drilling sorted.

Would you like more details on a specific aspect of the DUOMI CNC Drilling Machine? Contact us for a chance to get a free sample!