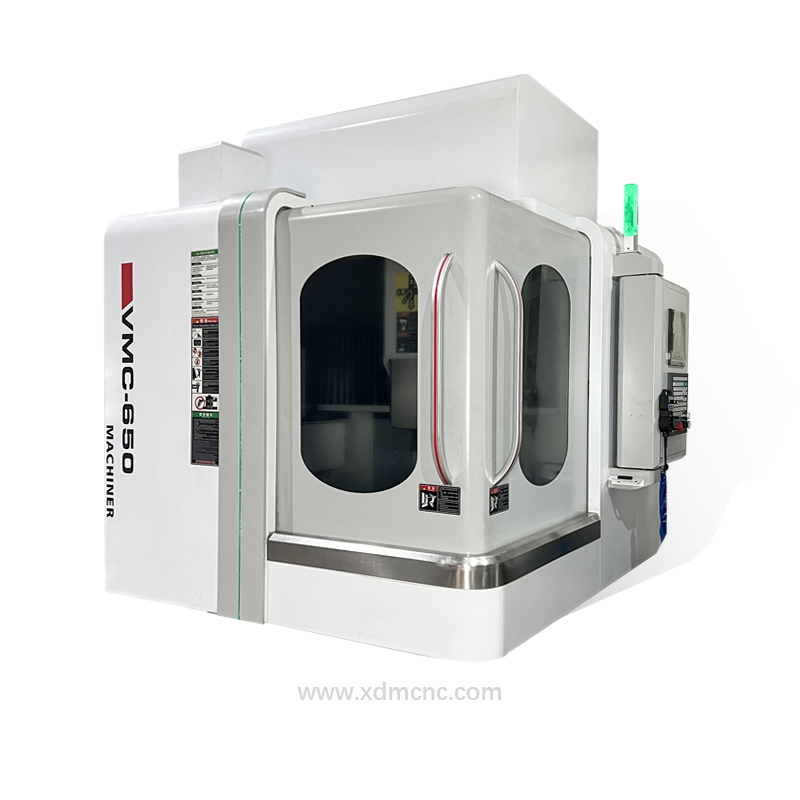

In modern manufacturing, efficient and accurate production tools are the key to improving product quality and production efficiency. DUOMI's drilling and tapping center, as a composite processing equipment integrating drilling and tapping, is gradually becoming the preferred solution for many manufacturing companies. It not only integrates advanced CNC technology, but also integrates the exquisiteness of mechanical design, providing a one-stop solution for the processing of complex parts.

DUOMI's drilling and tapping center, one-stop solution to complex parts processing problems

In terms of machining accuracy, DUOMI's drilling and tapping center demonstrates amazing capabilities. It can operate within a tiny error range, which is undoubtedly the greatest blessing for parts that require high-precision machining. For example, in the aerospace field, some key connectors and small precision parts, the drilling and tapping center can control the aperture machining accuracy within a very small range to ensure the perfect fit between parts, which is crucial to the safety and performance stability of the aircraft.

DUOMI's drilling and tapping center's high speed is also a major feature. Its spindle speed is extremely high, and it can quickly complete operations such as drilling and tapping. This high speed not only improves processing efficiency, but also improves processing quality to a certain extent. In the field of electronic product manufacturing, such as the processing of mobile phone shells, computer motherboards and other parts, the drilling and tapping center can quickly and accurately process many holes on thin plate materials to meet the needs of large-scale production.

DUOMI's drilling and tapping center, one-stop solution to complex parts processing problems

From the perspective of operational convenience, DUOMI'S drilling and tapping center is equipped with an advanced CNC system. Operators can easily control the operation of the drilling and tapping center by writing CNC programs. Moreover, modern drilling and tapping centers also have certain intelligent functions, which can monitor and analyze the data in the processing process in real time. If tool wear, abnormal processing parameters, etc. occur, it can send out alarms and make adjustments in time, reducing the scrap rate and production costs.

However, DUOMI's drilling and tapping centers also face some challenges. As the manufacturing industry's requirements for processing accuracy and efficiency continue to increase, drilling and tapping centers need to be continuously upgraded. At the same time, its high cost also makes some small and medium-sized enterprises have concerns when introducing it.

DUOMI's drilling and tapping center plays an extremely important role in the manufacturing industry. With its advantages of high precision, high speed and convenient operation, it promotes the development of precision manufacturing in various fields.