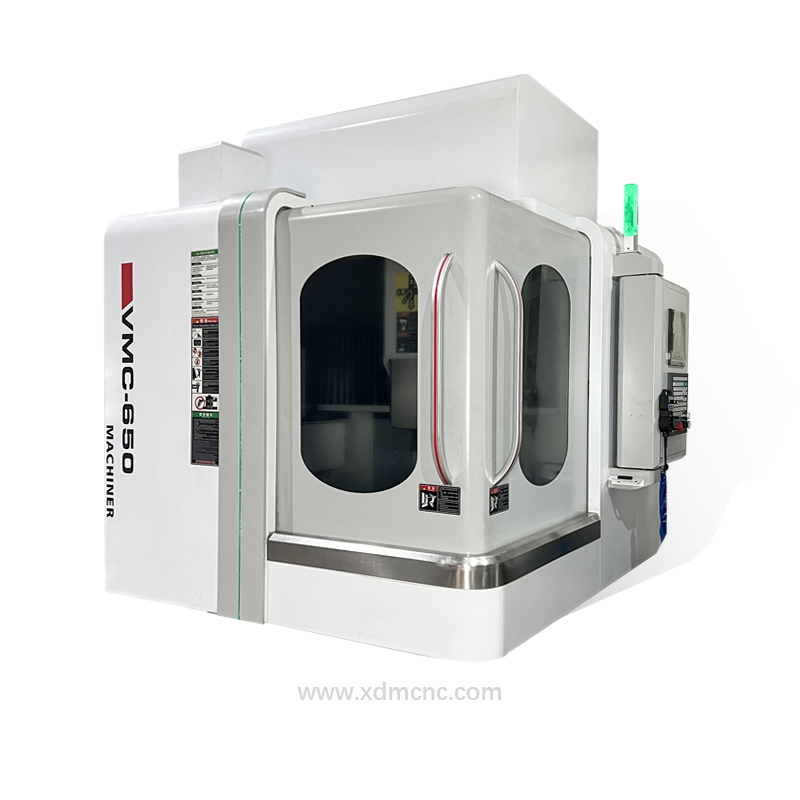

5 Axis Machining Center CNC Milling Machine VMC 650

CNC Drilling & Tapping Machine

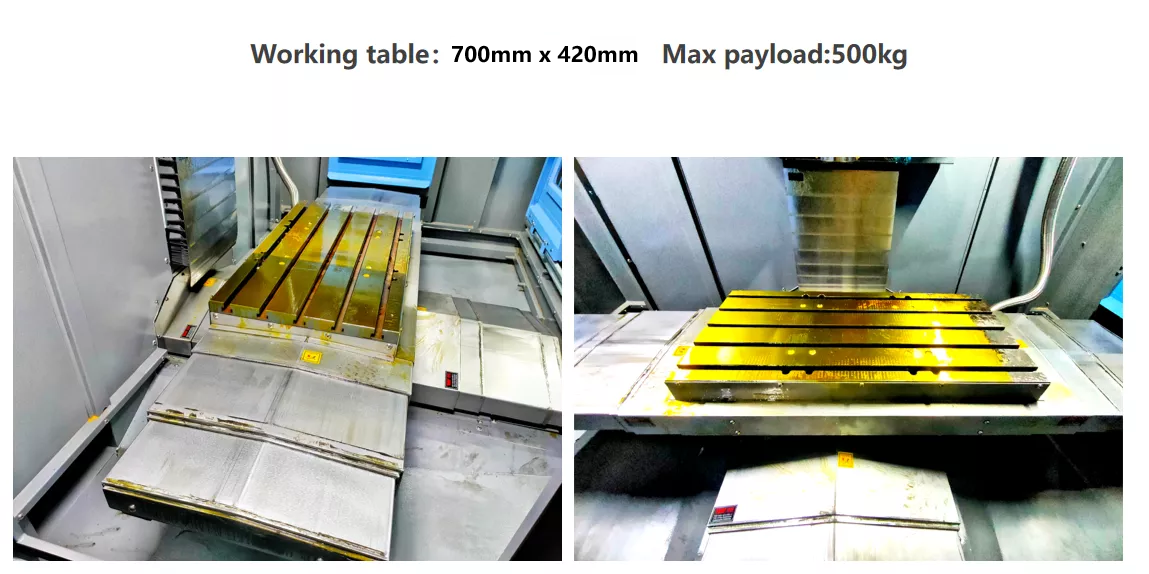

Model: VMC 650

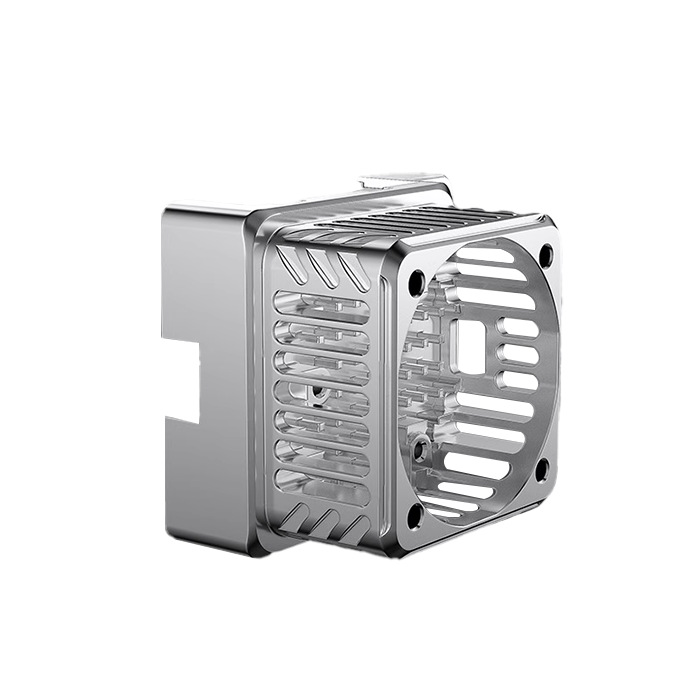

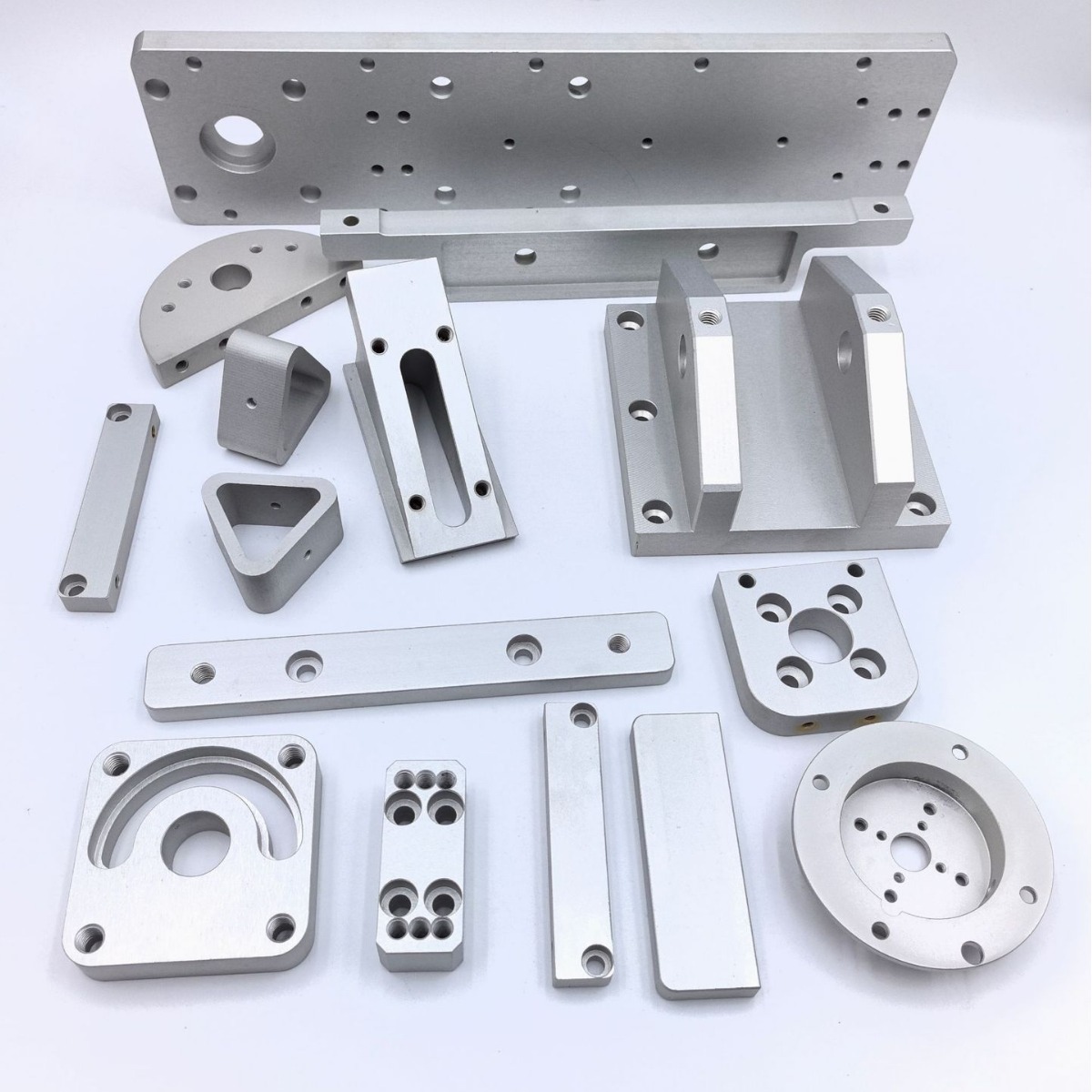

Function: Drilling & Milling

Application Materials: Iron, Copper, Aluminium, Brass, Steel, Zinc, Platinum etc.

Feature

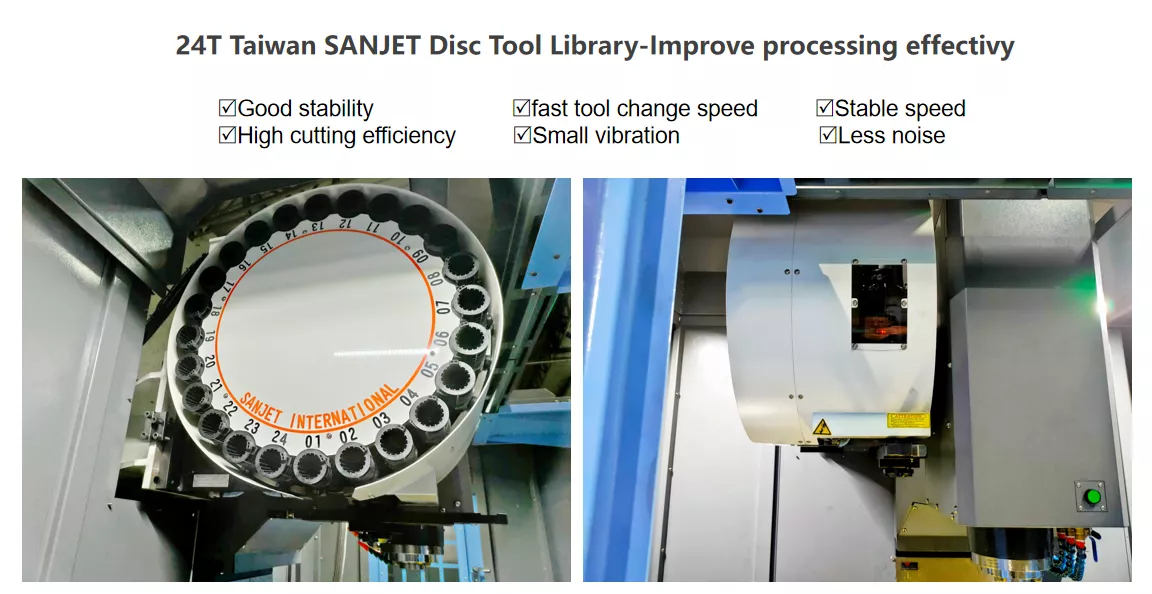

Factory Supply High-Quality 3-axis 4-axis 5 Axis Machining Center CNC Milling Machine

The DUOMI VMC650 vertical machining center is one of the most widely used, popular, and versatile models available. It is capable of machining 80% of the products on the market. This machine is primarily designed for processing complex 2D and 3D concave-convex models, as well as intricate cavities and curved surfaces.

Lead time (days) : 30 working days. (Standard Configuration)

Tip: Our CNC drilling and tapping machines support custom non-standard designs, machine color customization, and OEM branding. Start now to purchase and customize your own equipment, please contact us.

Request A Quote

Request A Quote