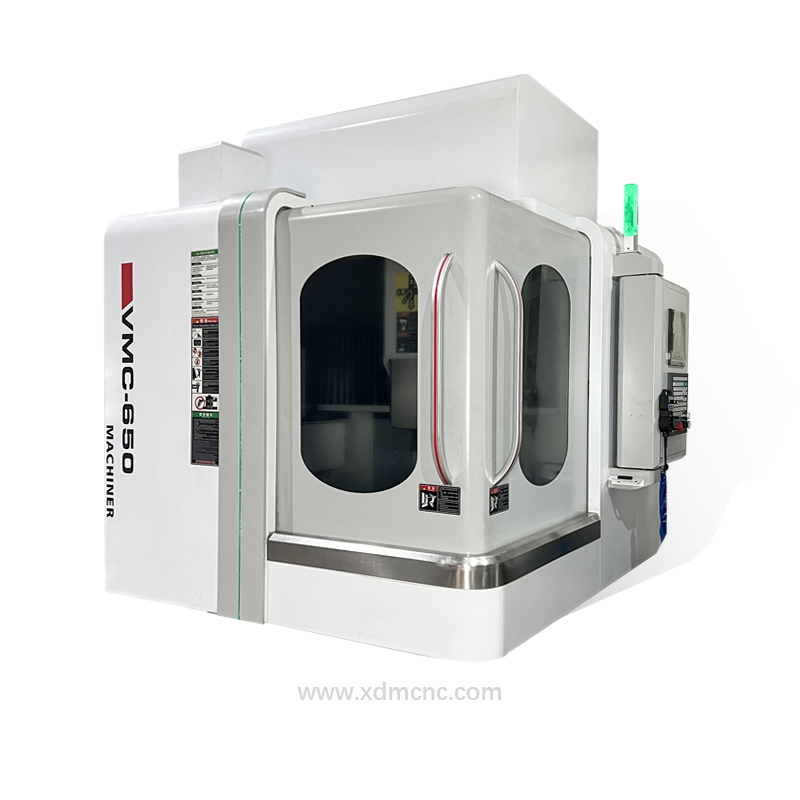

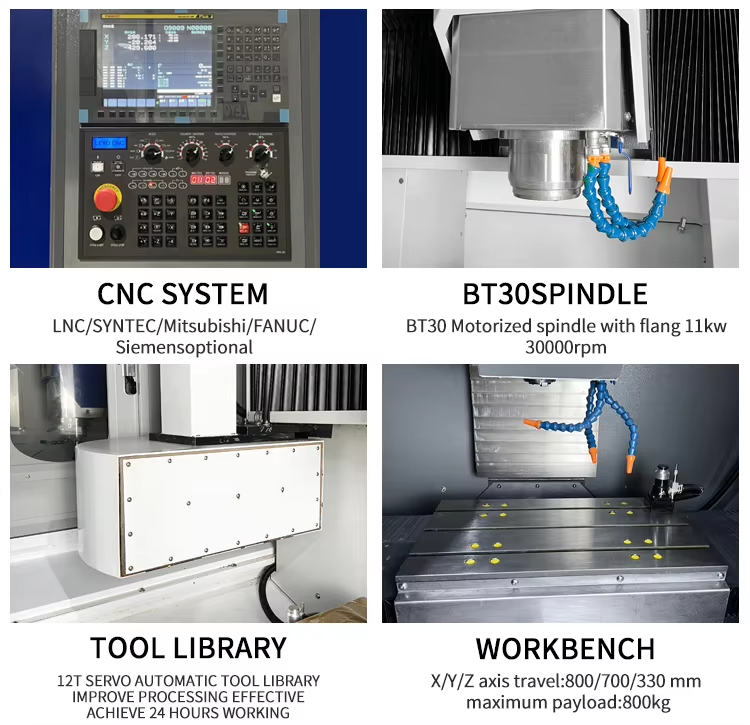

Versatile CNC Milling Machine VMC M8

CNC Drilling & Tapping Machine

Model: VMC M8

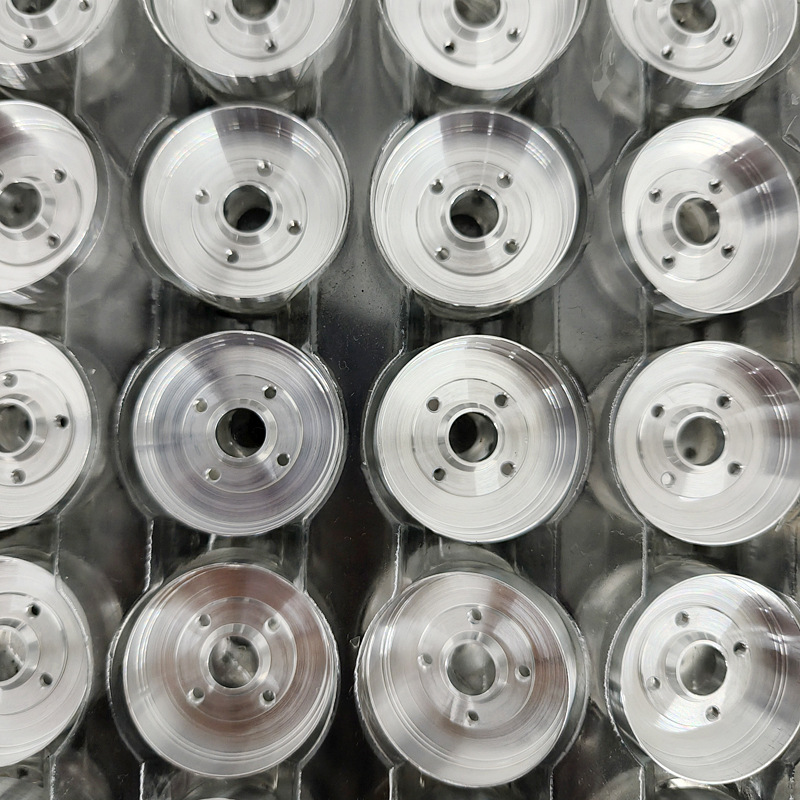

Function: Engraving & Milling

Application Materials: Iron, Copper, Aluminium, Brass, Steel, Zinc, Platinum etc.

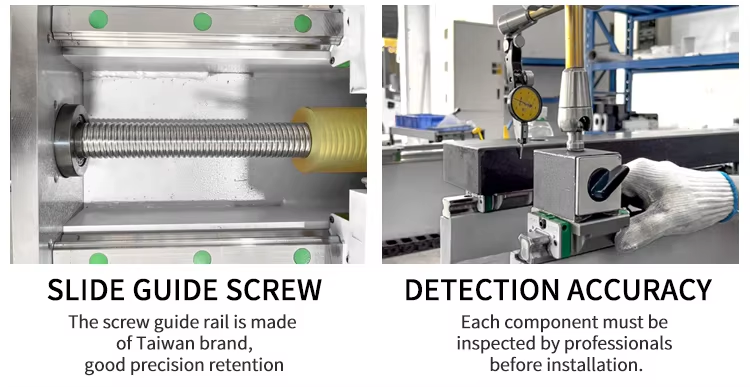

Feature

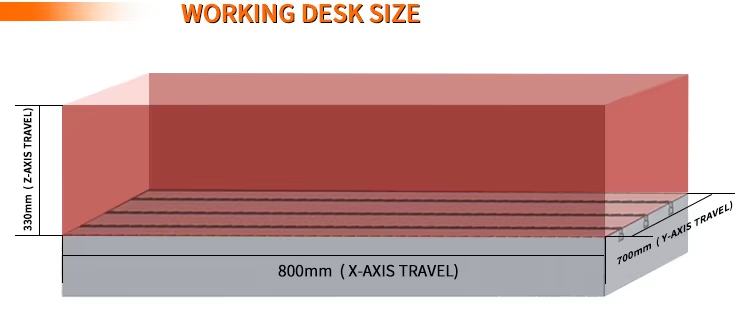

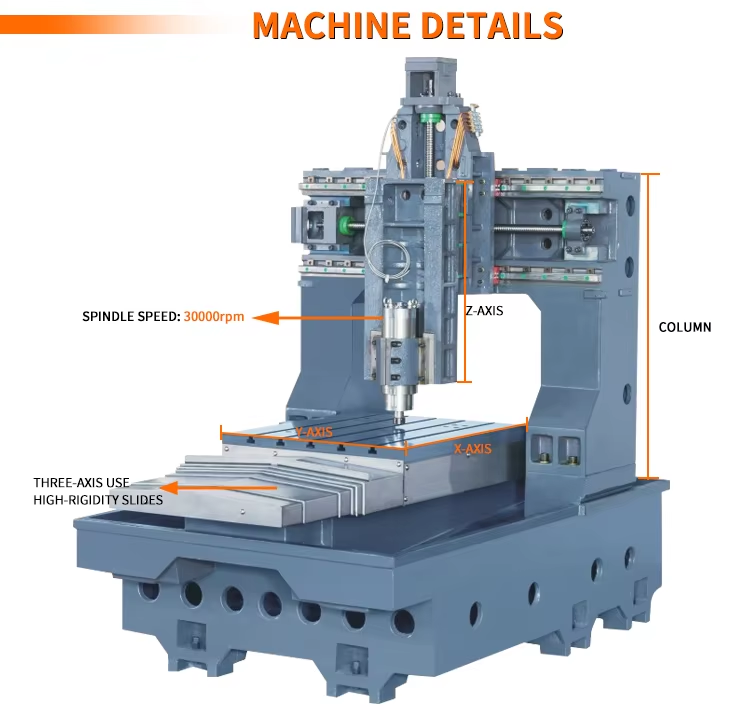

Versatile CNC Milling Machine for Precision Metalworking and Custom Parts Engraving with VMC M8

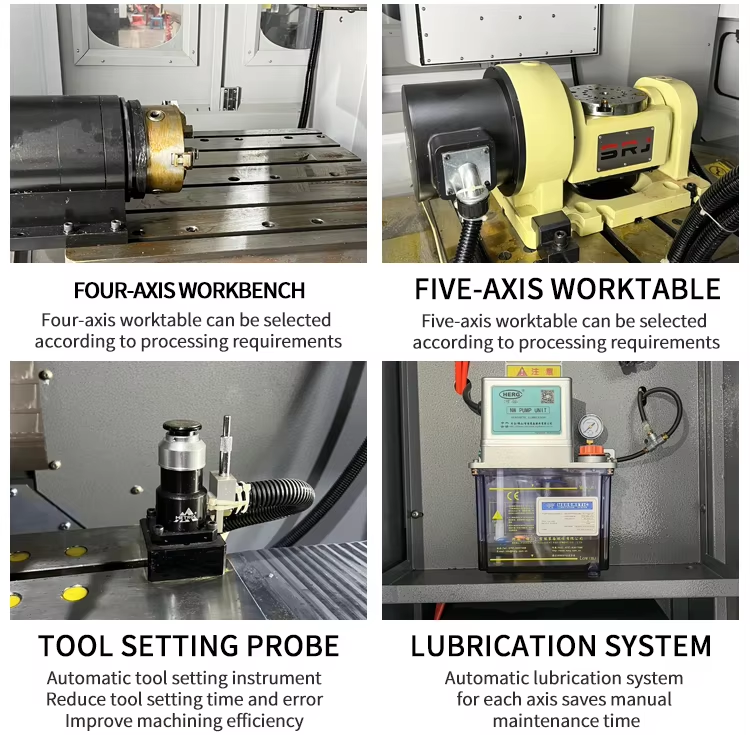

Optional Features:

Coolant Through Spindle

Chip Conveyor

4/5-Axis CNC Rotary Table

Oil Mist Separator

Oil Skimmer

We also provide additional machine accessories and tools, including:

Tool Holders

Collets

Cutting Tools

We offer a one-stop solution for all your machining needs. For more information, please contact us!

Lead time (days) : 30 working days. (Standard Configuration)

Tip: Our CNC drilling and tapping machines support custom non-standard designs, machine color customization, and OEM branding. Start now to purchase and customize your own equipment, please contact us.

Request A Quote

Request A Quote