DUOMI CNC recently completed a shipment of CNC drilling and tapping machines to a manufacturing customer, ensuring that the equipment arrived at the production line on schedule even under rainy and snowy weather conditions.

DUOMI CNC machines are being loaded for transport to the customer's location

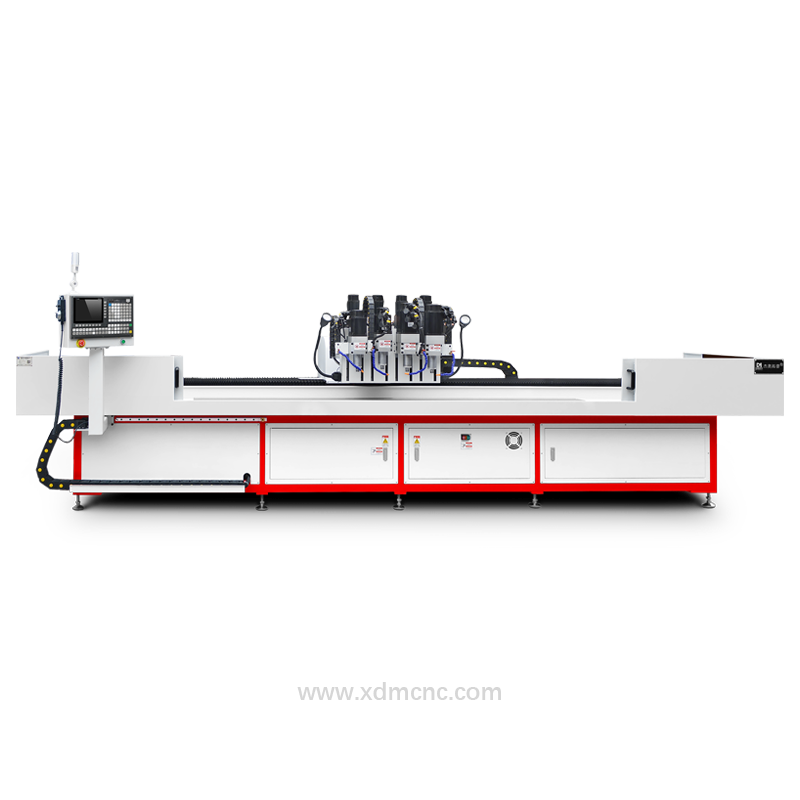

These CNC drilling machines and CNC tapping machines are used for high-precision hole drilling and thread forming on metal components such as stainless steel and structural steel parts. The customer selected DUOMI CNC due to its stable machine performance and reliable delivery service.

Before shipment, each CNC drilling and tapping machine was fully inspected and tested. The inspection process included checking spindle speed, drilling accuracy, tapping consistency, and electrical system stability. All machines passed internal quality standards before packaging.

To protect the machines during transportation, DUOMI CNC applied reinforced packaging solutions. Waterproof films, anti-rust coatings, and shock-absorbing materials were used to minimize the impact of humidity and vibration. The machines were fixed inside wooden crates suitable for long-distance transport.

DUOMI CNC machines are being loaded and shipped to the customer's site

On the delivery day, continuous rain and low temperatures increased the difficulty of loading. However, the logistics team completed the process safely using professional lifting equipment and strict safety controls. Each CNC machine was secured on the transport vehicle to prevent movement during transit.

After arrival at the customer's factory, the machines were unloaded and inspected. Trial drilling and tapping operations were carried out on metal samples. The results showed stable hole accuracy, smooth threads, and consistent processing quality.

DUOMI CNC machines are being loaded onto trucks for delivery to the customer

This successful delivery demonstrates DUOMI CNC's ability to provide not only reliable CNC drilling and tapping machines but also dependable logistics support. For manufacturers, on-time delivery of CNC equipment is essential for maintaining production efficiency and meeting order deadlines.

Even in adverse weather conditions, DUOMI CNC continues to ensure that its CNC drilling machines and CNC tapping machines reach customers' workshops safely and on time. This approach helps customers maintain production continuity and achieve long-term manufacturing stability.