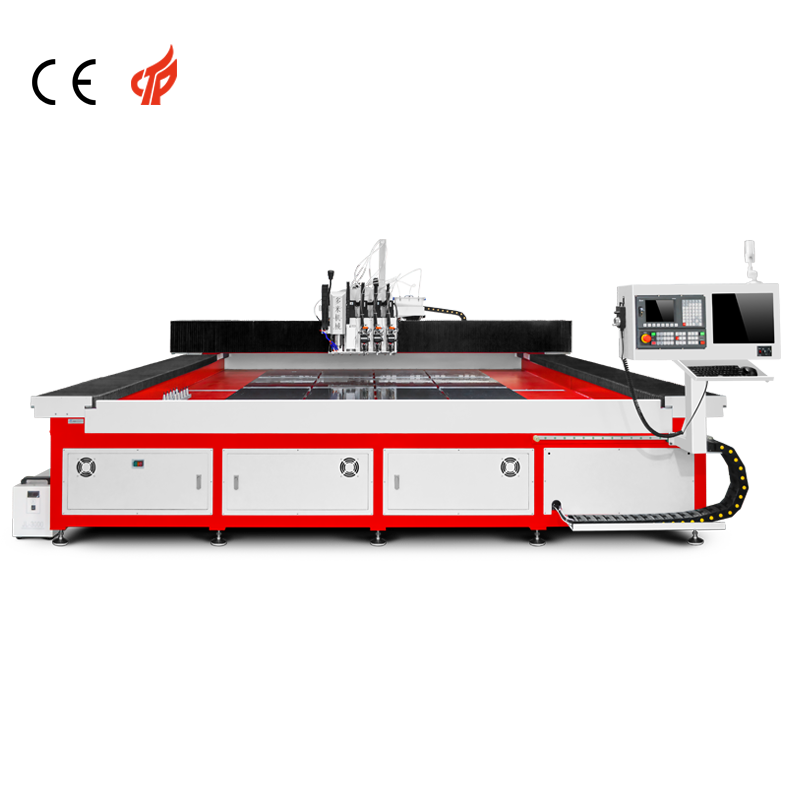

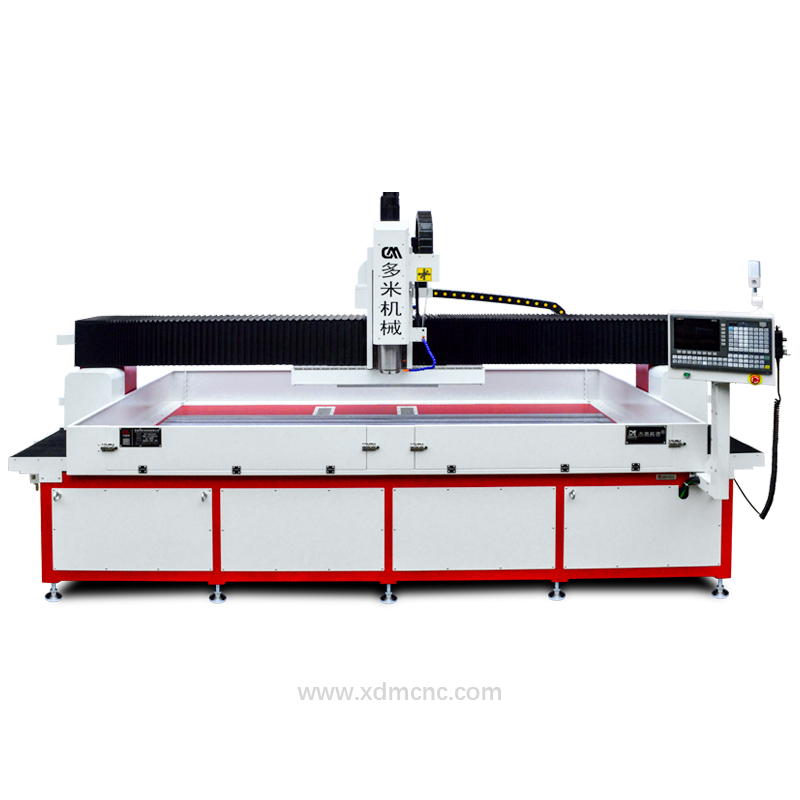

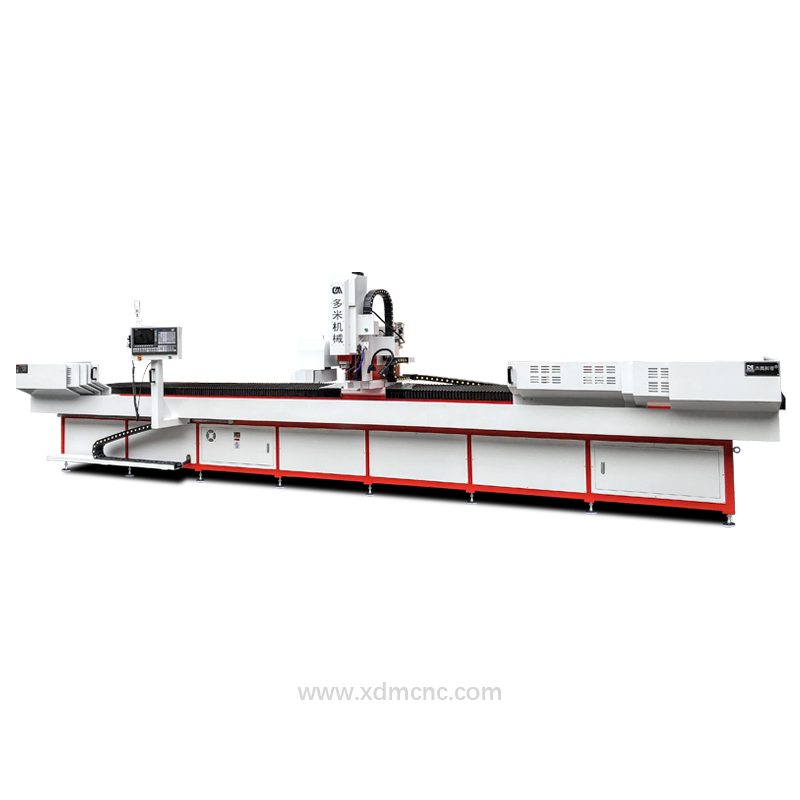

Gantry CNC drilling and tapping riveting complex machine DHC-3028N10

CNC Drilling & Tapping Machine

Model: DHC-3028N10

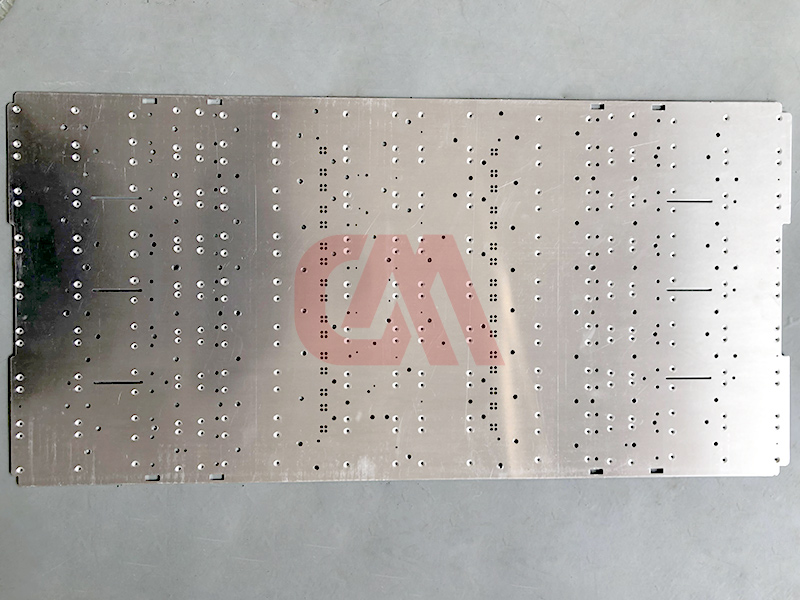

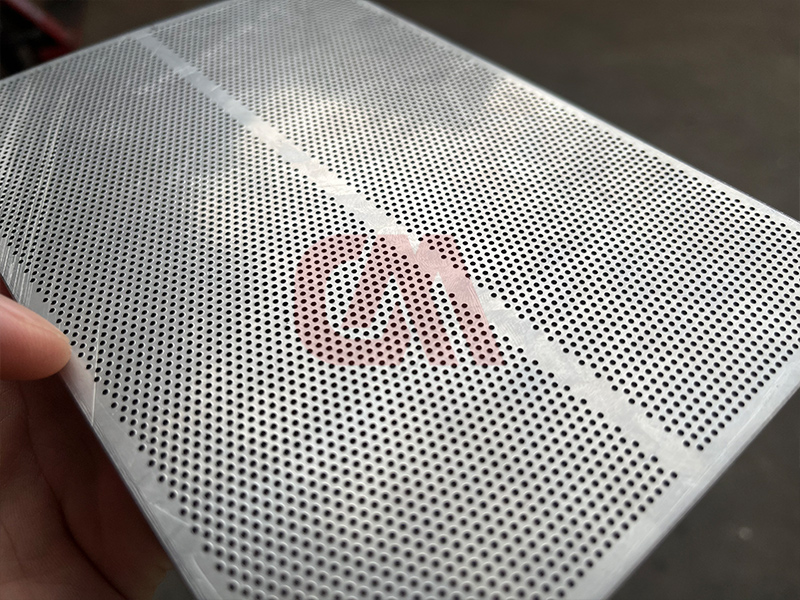

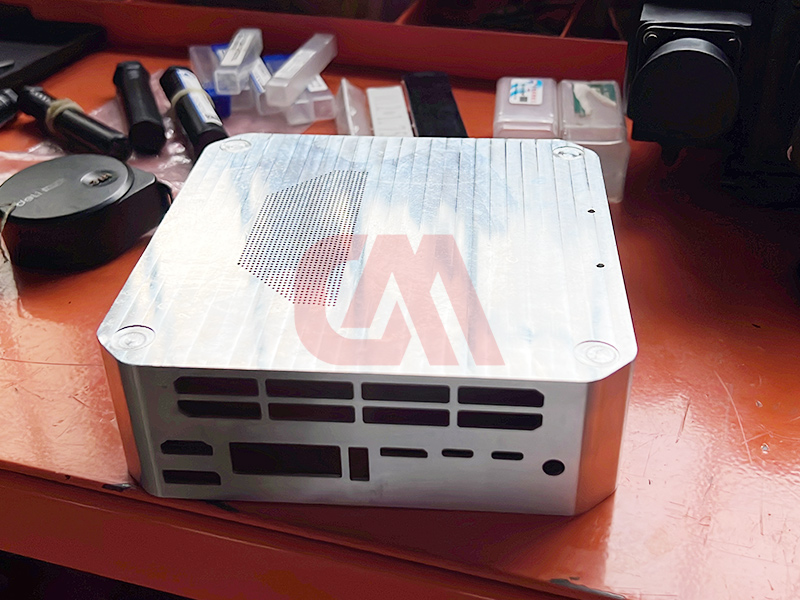

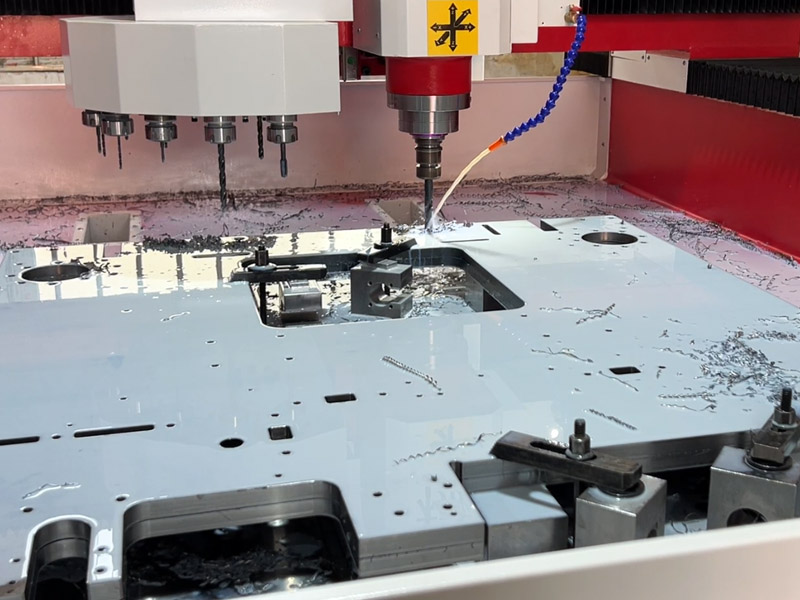

Function: CNC Drilling, Tapping & Riveting complex

Application Materials: Iron, Copper, Aluminium, Brass, Steel, Zinc, Platinum etc.

Feature

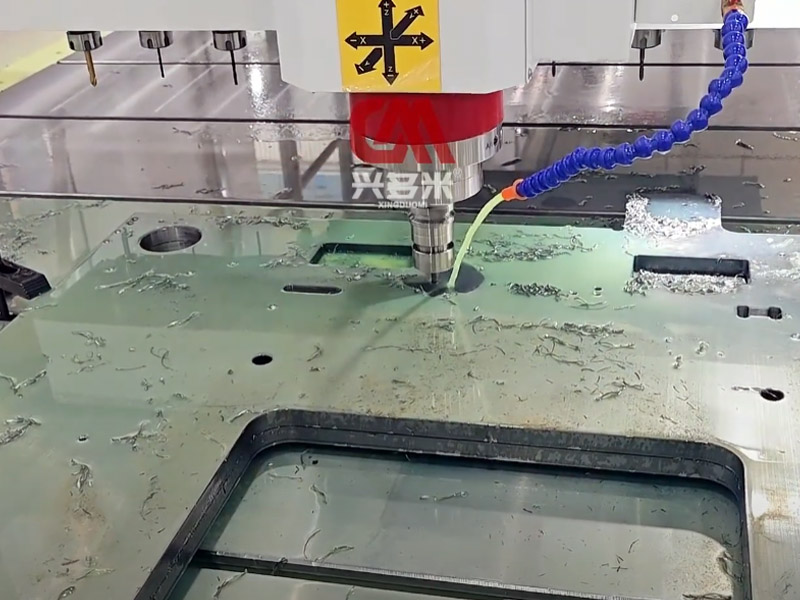

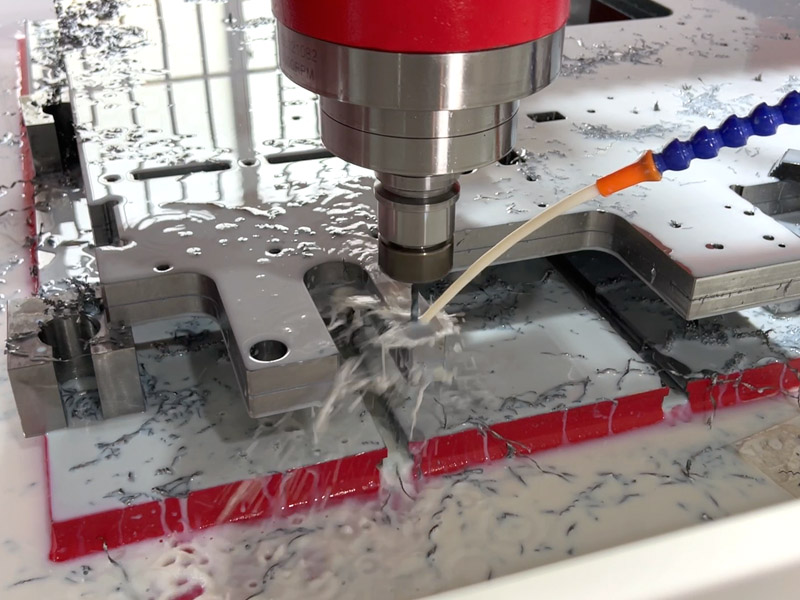

A multi-functional CNC machine integrating CCD visual imaging, automatic driling chamfering and automatic riveting.

CCD vision system automatically scans and identifies hole positions, accurate and eficient.

After the vibrating plate feeds nails, the machine tool automatically pulls the rivet, and the 3 riveting guns switch the rivet action and rivet diameter at will.

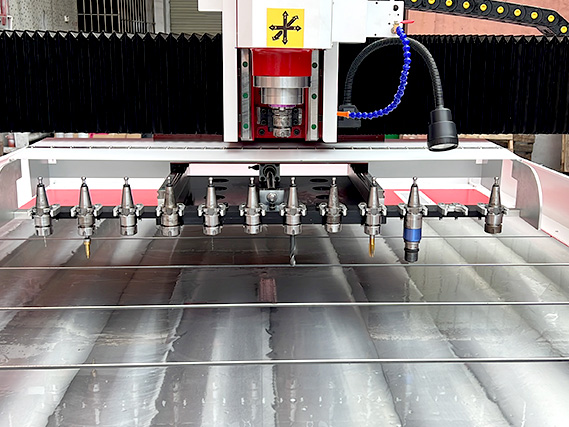

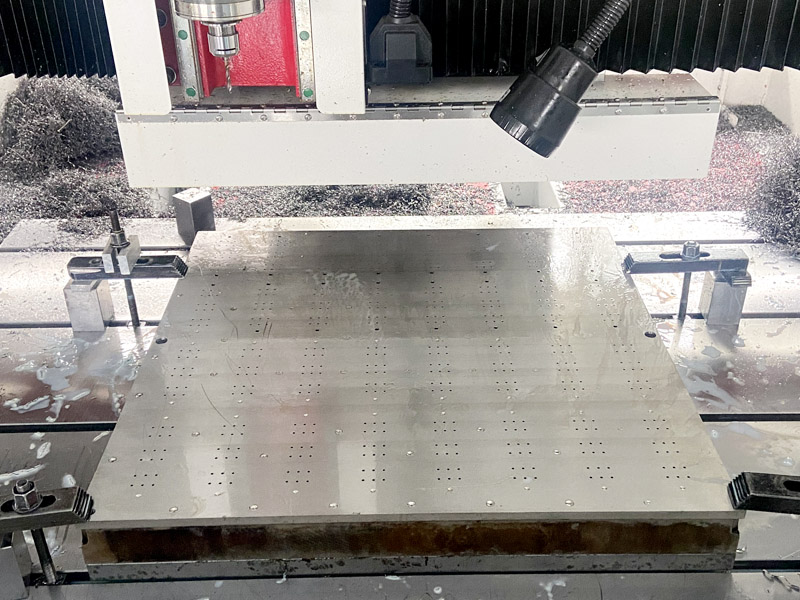

The Y-axis is a dual drive, and the heavy-duty ball linear slide rai is combined with a double-set transmission mechanism to ensure the smooth operation of the moving beam.

I adopts widened and thickened moving beam type door structure form, and the spindle will not shake when accelerating and decelerating, and the speed is fast and stable.

The machine tool side is equipped with a row tool magazine, and the multi-specification hole diameter drling chamfering process is clamped at one time to complete the processing.

CNC drilling and tapping riveting complex machine DHC-3028N10, Non-standard CNC Gantry Drilling, Tapping, and Rivet Pulling Machine with Visual Positioning.

Lead time (days) : 30 working days. (Standard Configuration)

Tip: Our CNC drilling and tapping machines support custom non-standard designs, machine color customization, and OEM branding. Start now to purchase and customize your own equipment, please contact us.

Request A Quote

Request A Quote