Achieve Unmatched Precision and Efficiency

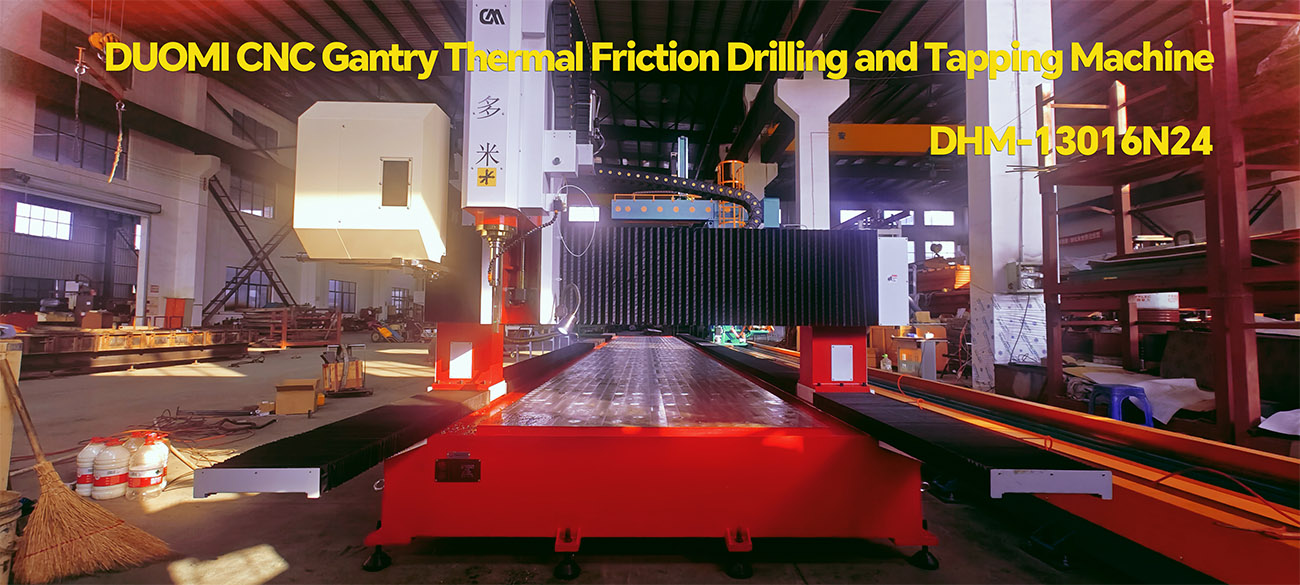

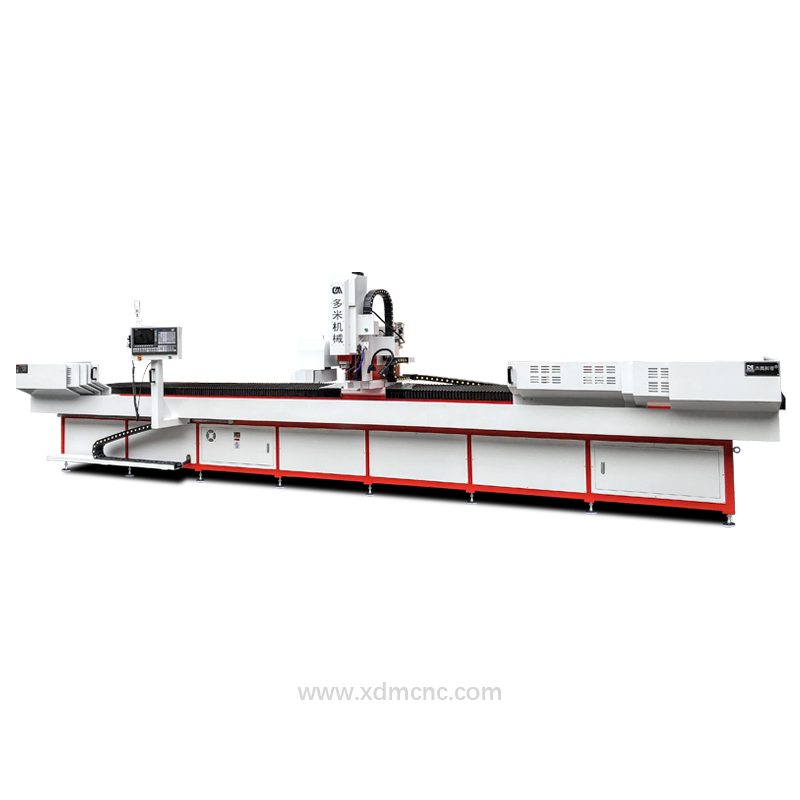

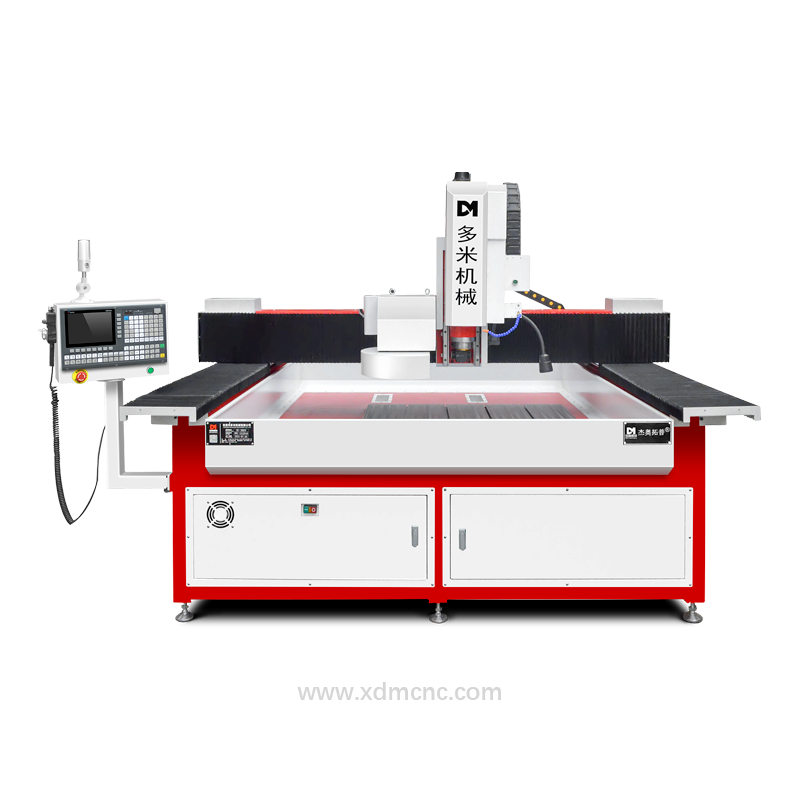

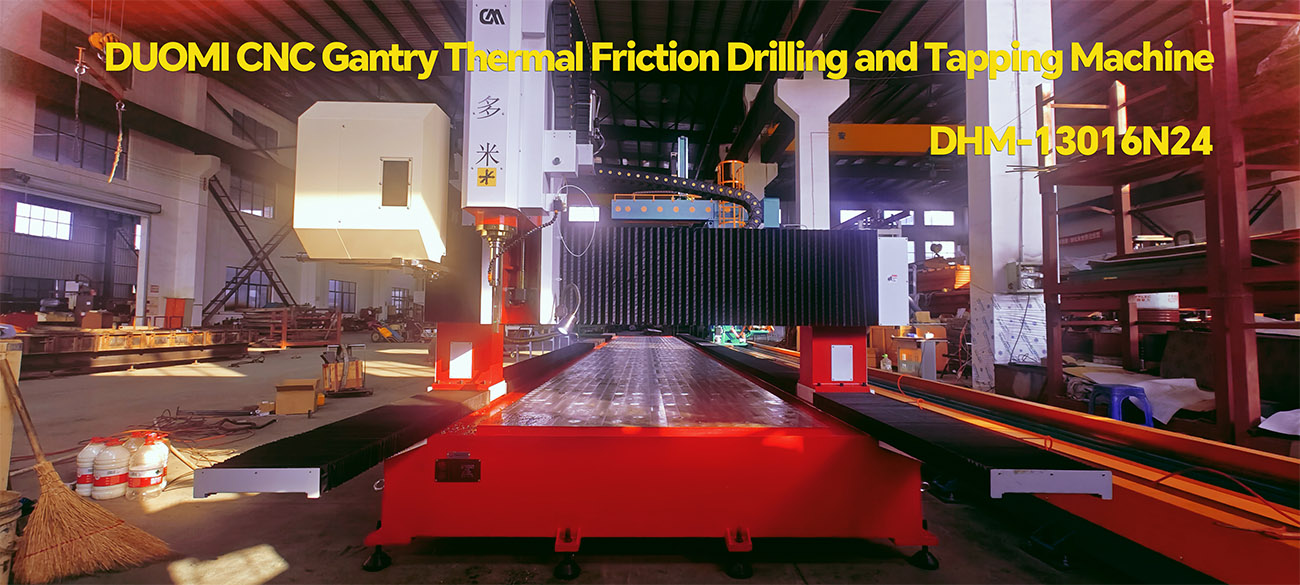

The CNC Gantry Thermal Friction Drilling and Tapping Machine is engineered for high-performance drilling and tapping on a wide range of materials. Whether you are working with thick steel plates, structural components, or other heavy-duty parts, this machine guarantees consistent accuracy and superior surface finishes. The gantry design ensures stability, minimizing vibrations and guaranteeing precision during the most demanding operations.

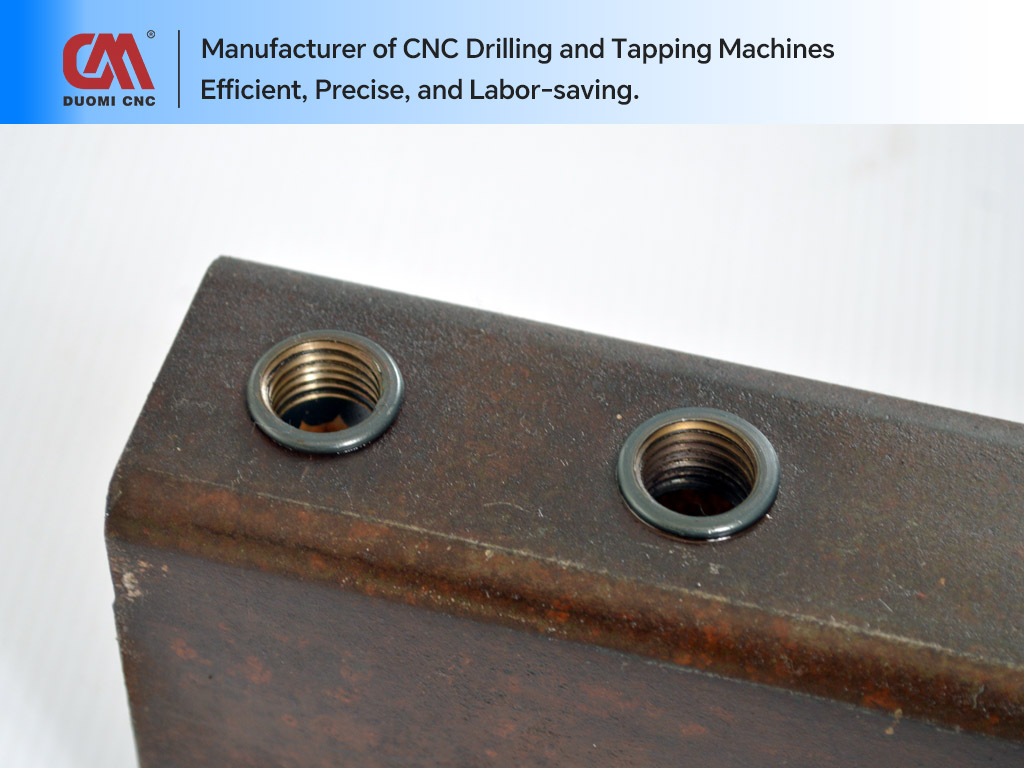

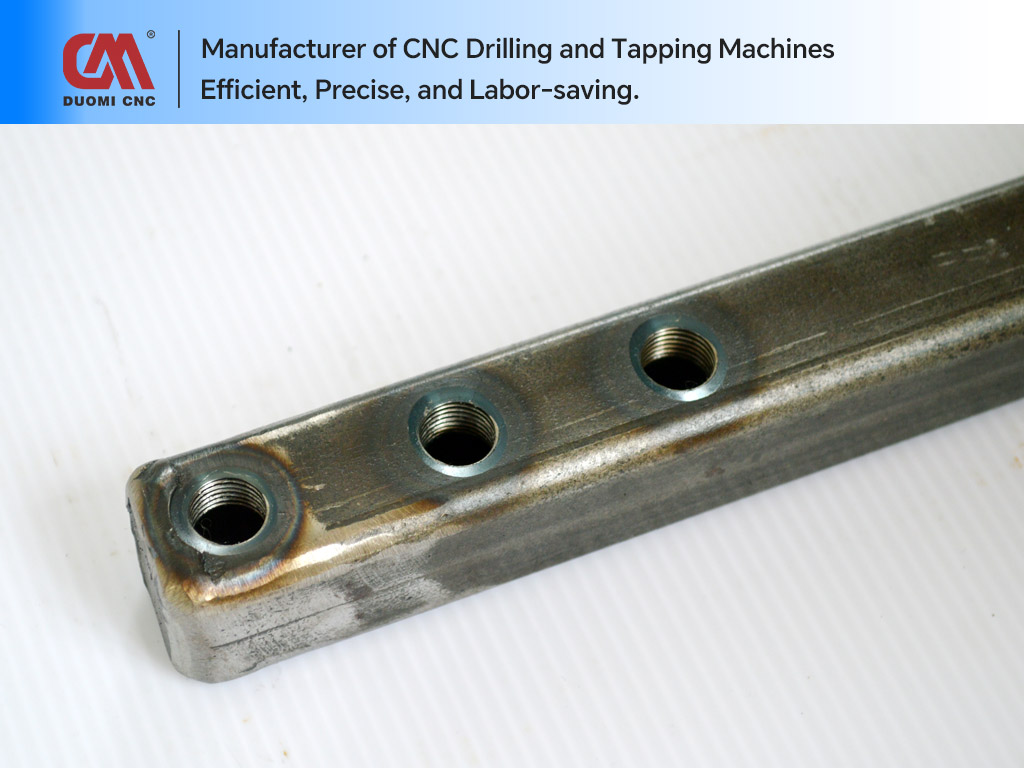

Thanks to its thermal friction drilling capability, the DUOMI CNC machine can create clean, burr-free holes with minimal material deformation. This process generates heat at the tip of the drill, allowing for faster, more efficient drilling of metals that would otherwise be difficult to machine using conventional methods.

High Rigidity, High Performance

Built for maximum rigidity, the DUOMI CNC Gantry Thermal Friction Drilling and Tapping Machine features an imported BT30 spindle, ideal for various tapping, drilling, and milling tasks. The machine’s robust gantry structure ensures stable, high-precision machining on large and heavy workpieces without compromising performance.

The HIWIN / TBI high-precision linear guide rails and ball screws are sourced from Taiwan and provide exceptional accuracy, smooth motion, and low noise during operation. These precision components make this machine ideal for industries such as automotive, aerospace, and heavy machinery, where high-tolerance and repetitive processes are essential.

Streamlined Operations with Advanced Automation

At DUOMI CNC, we understand the importance of efficiency. That's why the CNC Gantry Thermal Friction Drilling and Tapping Machine is equipped with a disc-type tool magazine capable of holding up to 10 tools. This allows for quick, automatic tool changes, ensuring uninterrupted production and reduced downtime. The machine’s ability to automatically switch between different tool sizes and diameters makes it a perfect solution for mass production in complex machining environments.

The machine is equipped with absolute value servo motor drive control, which guarantees high positioning accuracy, fast response, and long-lasting stability. Additionally, the lubrication system is designed to minimize maintenance, ensuring reliable, ongoing performance. The system supplies consistent lubrication to each axis, reducing the risk of wear and ensuring smooth operation across long production runs.

Tested for Maximum Precision

To guarantee the highest level of performance, every DUOMI CNC Gantry Thermal Friction Drilling and Tapping Machine undergoes precision testing with API laser measurement systems imported from the U.S. After assembly, the machine is fine-tuned to ensure that the overall precision remains within a tolerance of 0.02mm, a mark of quality that ensures your machining tasks are completed with the utmost precision, every time.

Built for Heavy-Duty Applications

With its heavy-duty gantry design, this CNC machine is built to handle even the toughest tasks. The wide, thick, and heavy moving beam structure ensures the machine can handle large, heavy parts without compromising speed or accuracy. The machine’s stable, vibration-free operation during acceleration and deceleration ensures a smooth, efficient machining process, even during high-speed operations.

Why Choose DUOMI CNC?

DUOMI CNC has built a reputation for providing reliable, high-performance CNC machinery to industries worldwide. Our CNC Gantry Thermal Friction Drilling and Tapping Machine is no exception. Designed to meet the high demands of precision machining, this machine is equipped with the latest technology to increase your production efficiency while ensuring minimal downtime.

We pride ourselves on not just providing a machine, but a solution that enhances your manufacturing process. Our advanced automation, robust design, and high precision give you the competitive edge you need in today's fast-paced industrial landscape.

Ready to Take Your Production to the Next Level?

If you’re looking to boost your machining efficiency while maintaining high precision, the DUOMI CNC Gantry Thermal Friction Drilling and Tapping Machine is the solution. Contact us today to learn more about this powerful machine and how it can revolutionize your manufacturing processes.

Key Features:

Thermal friction drilling and tapping for burr-free, high-precision holes

BT40 mechanical spindle for heavy-duty performance

HIWIN / TBI high-precision guide rails and ball screws for stability and low noise

24-tool capacity disc-type tool magazine for automatic tool switching

Absolute value servo motor drive for high accuracy and fast response

API laser testing for precision within 0.02mm

Heavy-duty gantry structure for stable machining of large workpieces

Request A Quote

Request A Quote