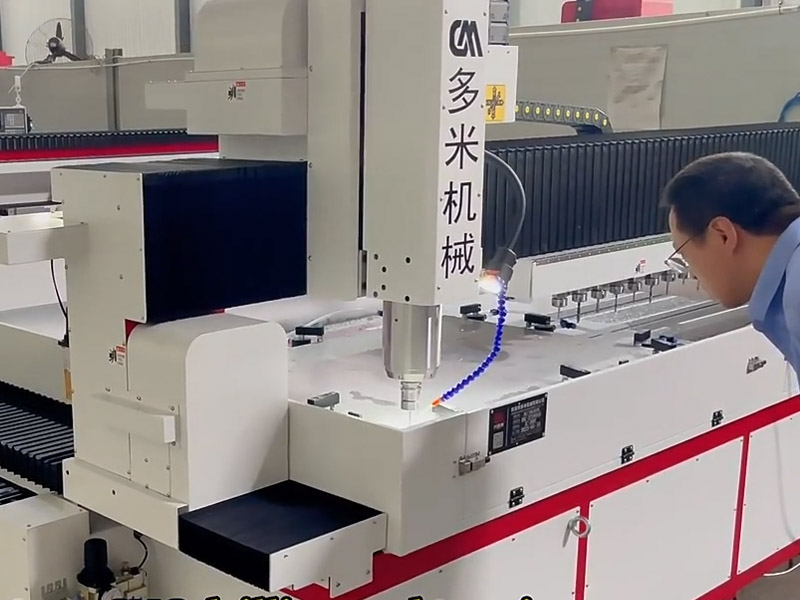

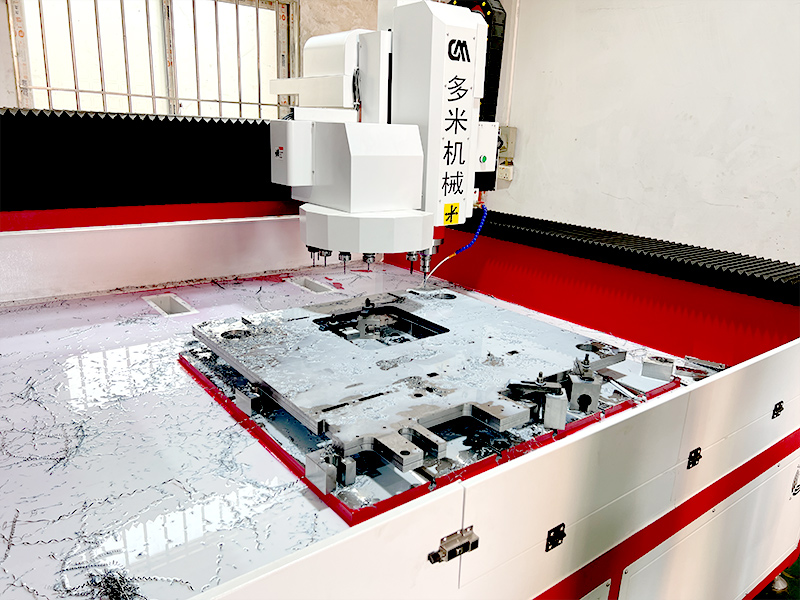

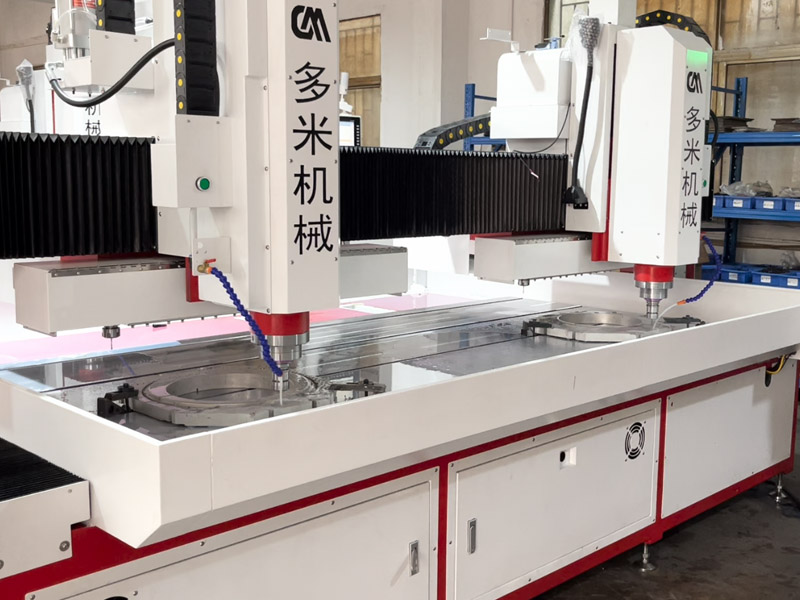

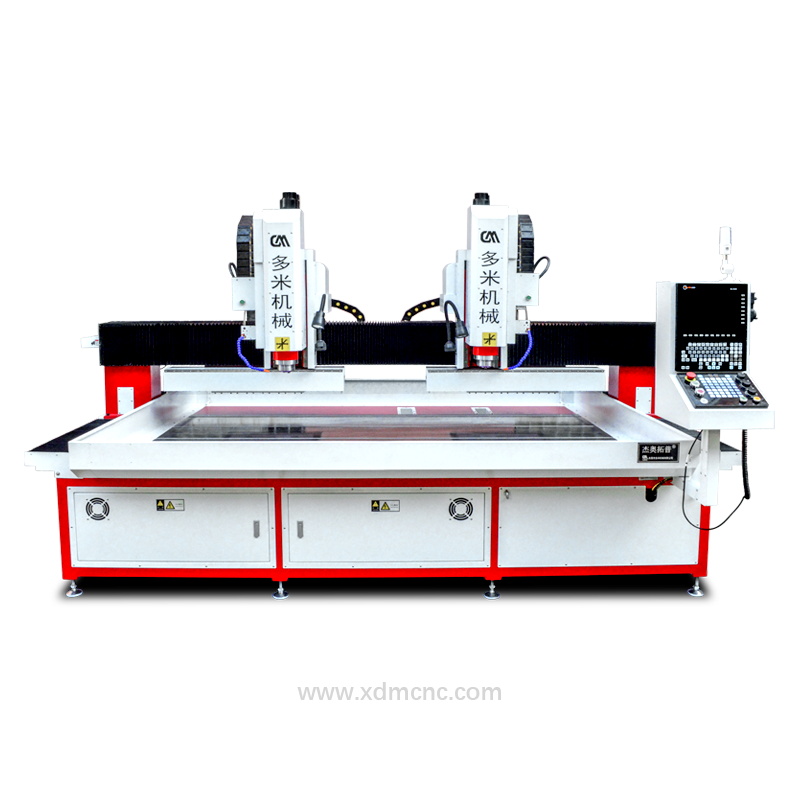

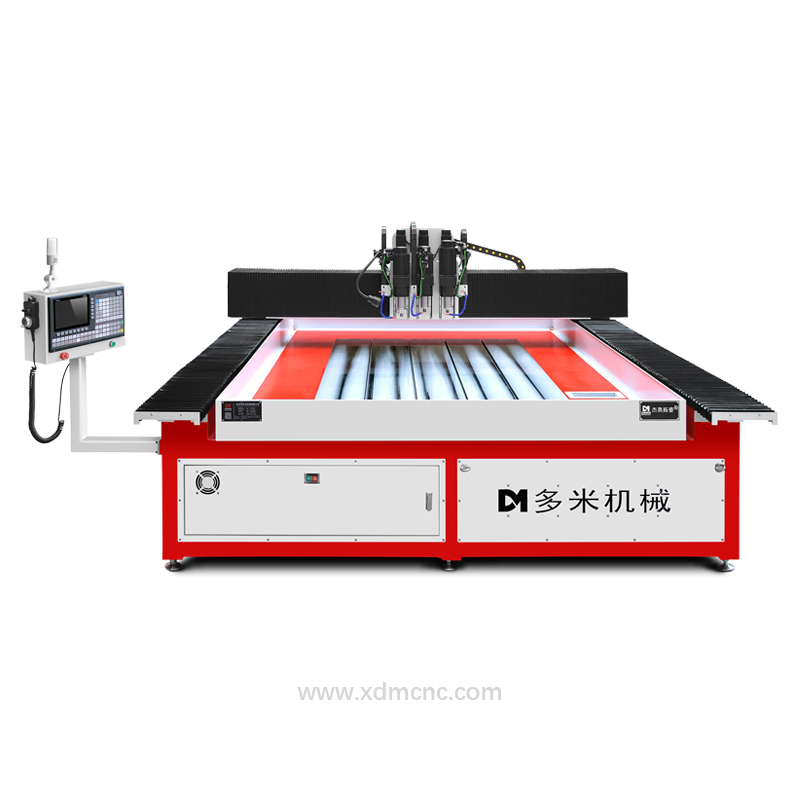

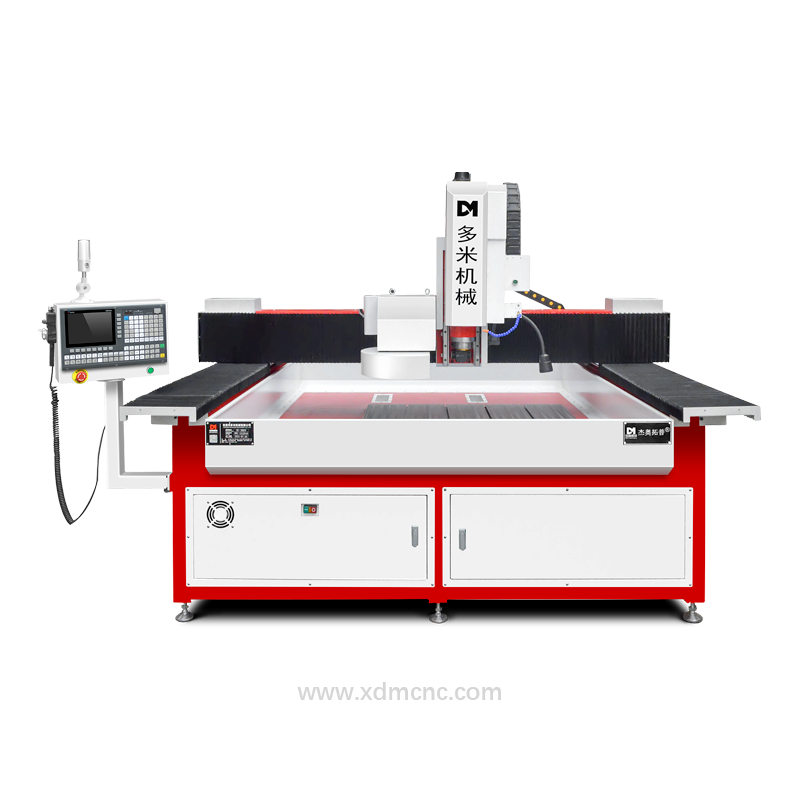

Double Spindle Gantry-Type CNC Drilling and Tapping Machine with automatic tool change

CNC Drilling & Tapping Machine

Model: DNC-1226N20

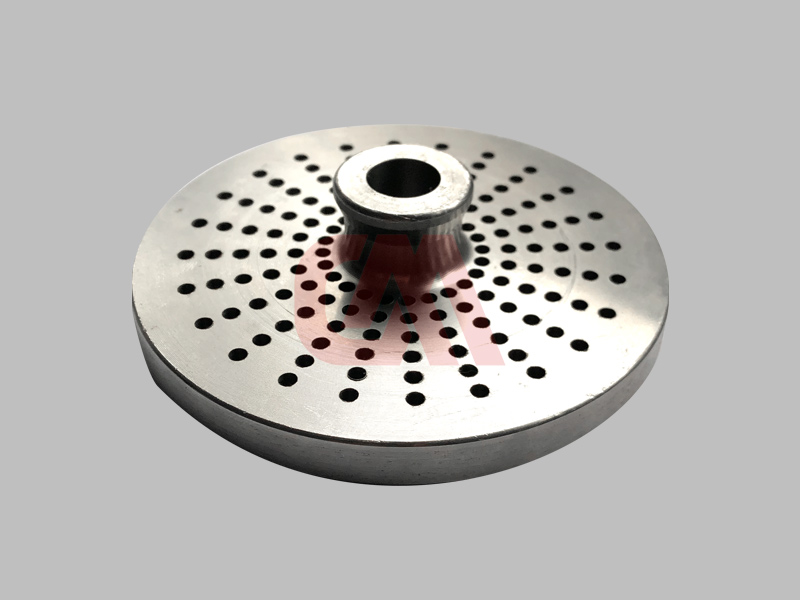

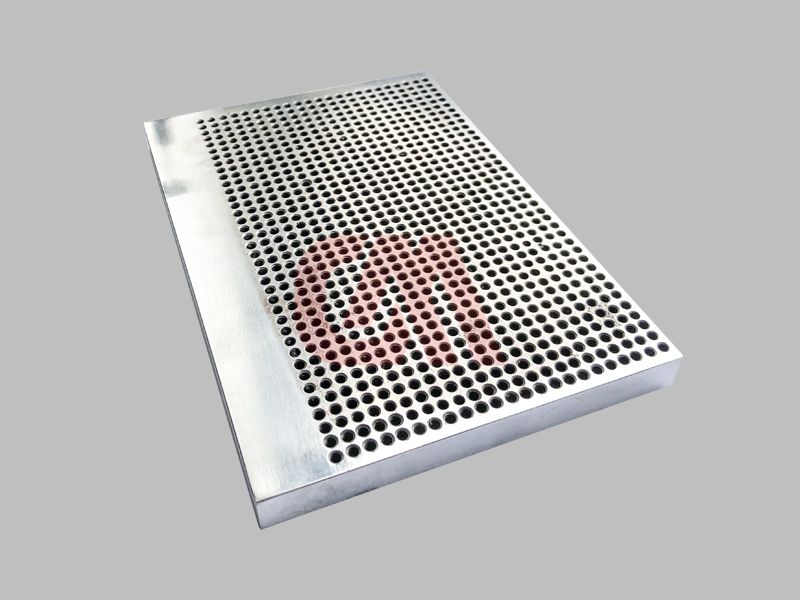

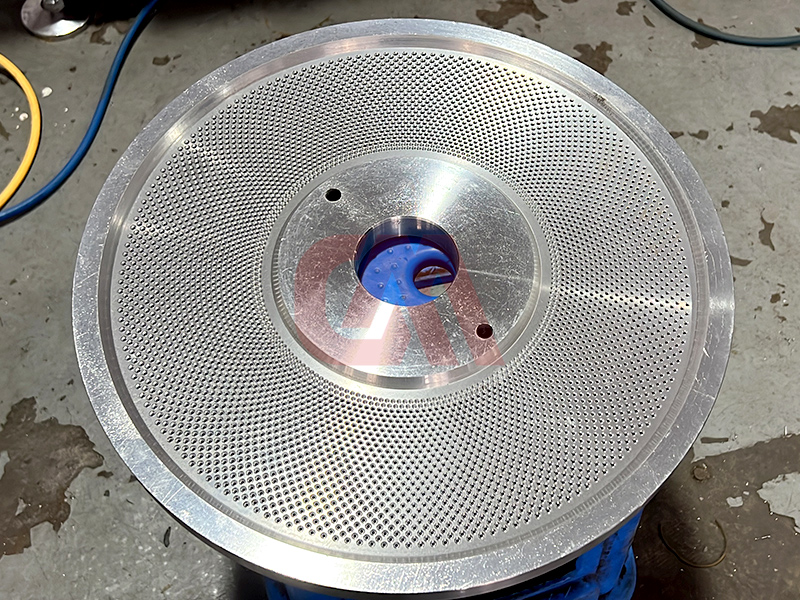

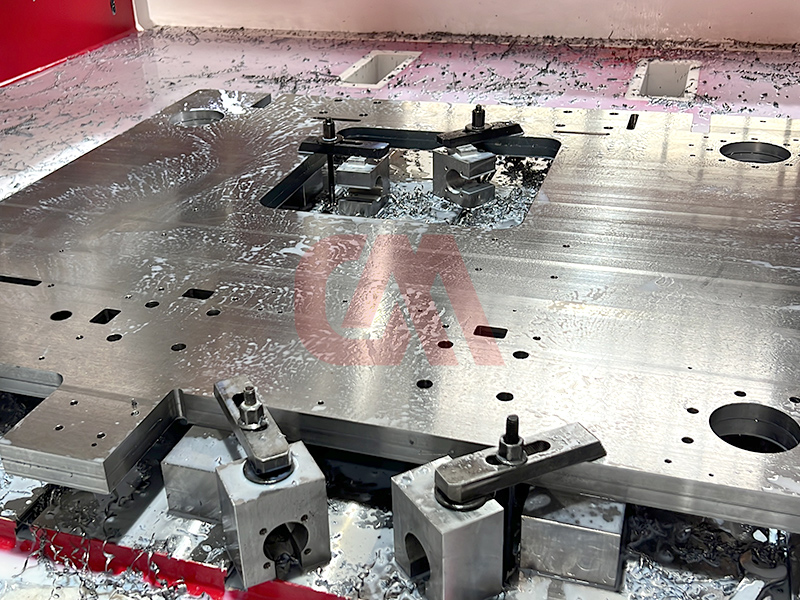

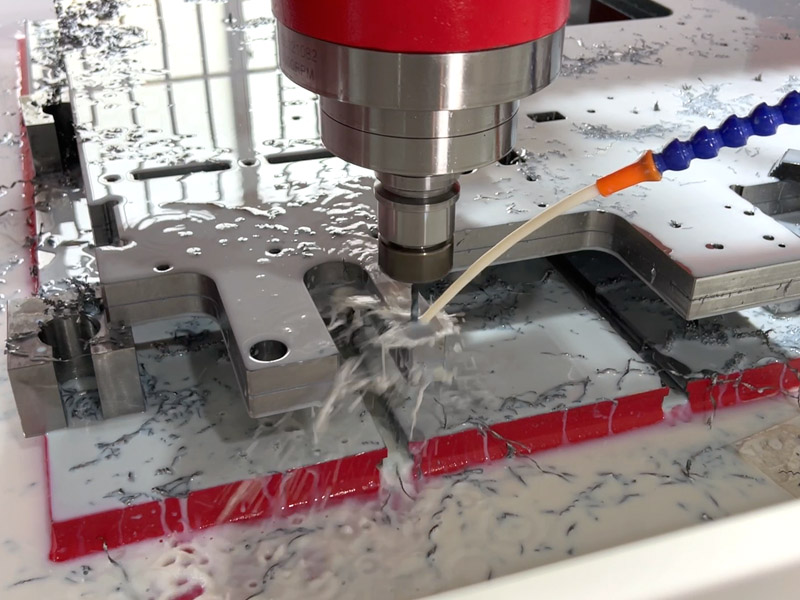

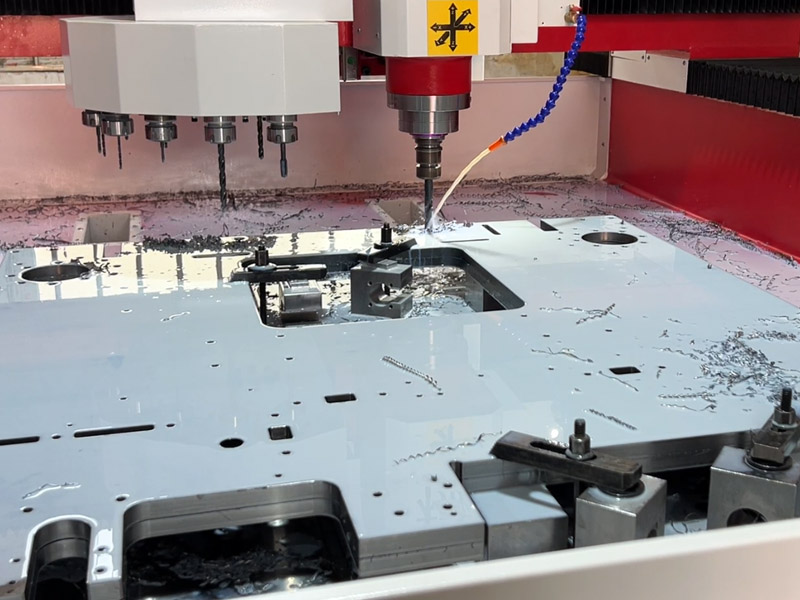

Function: Drilling, Tapping & Milling

Application Materials: Iron, Copper, Aluminium, Brass, Steel, Zinc, Platinum etc.

Feature

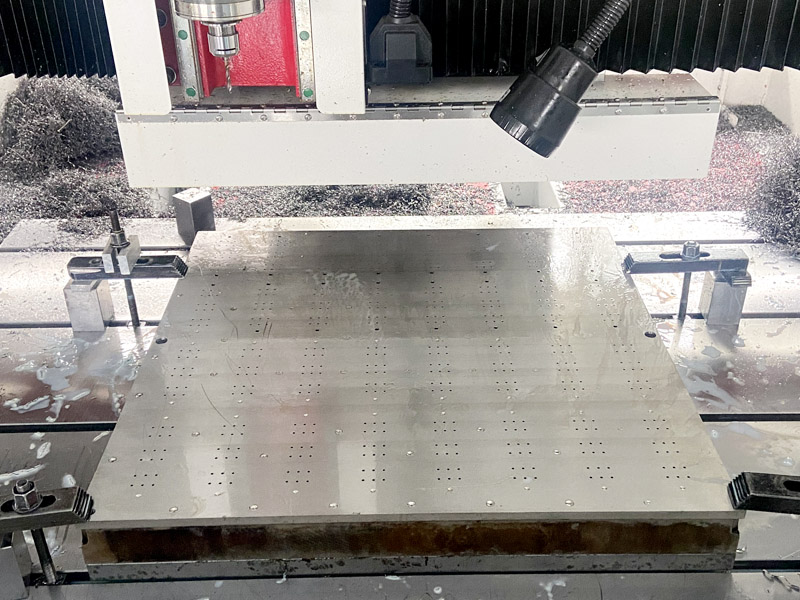

A Gantry-Type CNC Drilling and Tapping Machine is a high-precision machining tool designed for automated drilling and tapping operations on large workpieces. It features a gantry structure, where the spindle moves along the X, Y, and Z axes, providing stability and accuracy for complex machining tasks.

Equipped with Computer Numerical Control (CNC), this machine ensures high-speed, efficient, and precise hole-making and threading in various materials, including steel, aluminum, and composites. Its rigid gantry frame allows for heavy-duty processing, making it ideal for applications in aerospace, automotive, shipbuilding, construction, and machinery manufacturing.

With multi-axis control, automatic tool changing, and high-speed spindles, gantry-type CNC drilling and tapping machines significantly enhance production efficiency, reduce labor costs, and ensure consistent quality in mass production environments.

Maximize your production with the Gantry Type CNC Drilling Machine, built for precision and power. Double spindle Gantry CNC drilling and tapping machine, DNC-1226N20 High precision automatic tool change multifunction CNC drilling tapping and milling machine with Dual Spindles.

Lead time (days) : 30 working days. (Standard Configuration)

Tip: Our CNC drilling and tapping machines support custom non-standard designs, machine color customization, and OEM branding. Start now to purchase and customize your own equipment, please contact us.

Request A Quote

Request A Quote