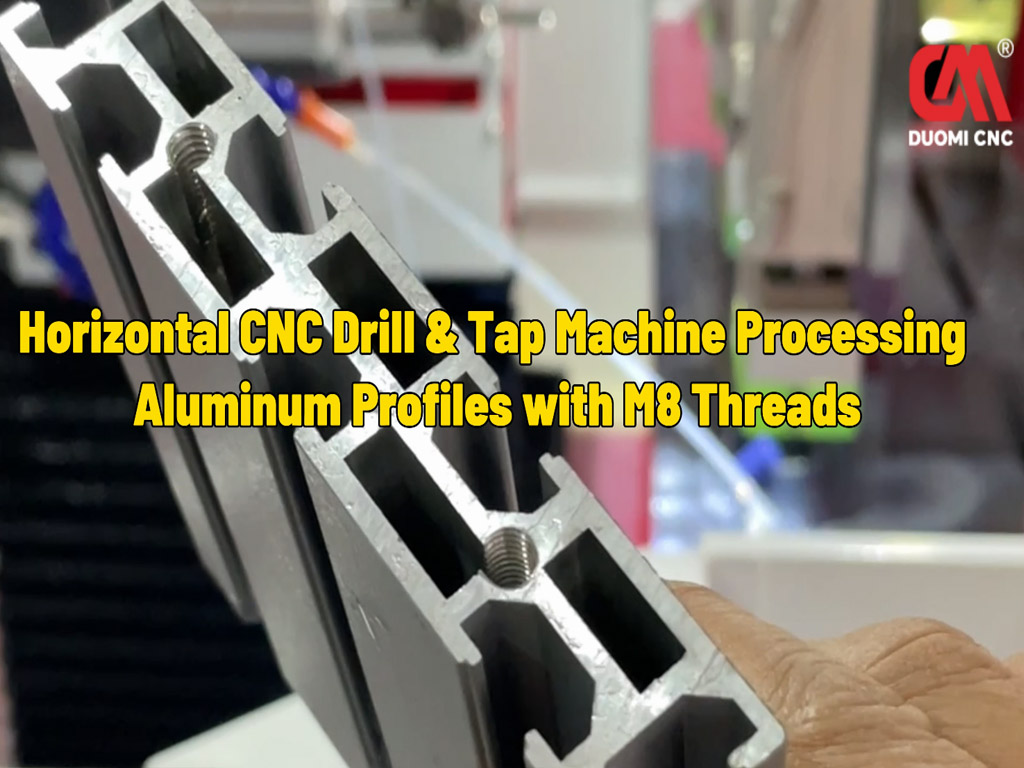

Horizontal CNC drilling and tapping machines original manufacturer

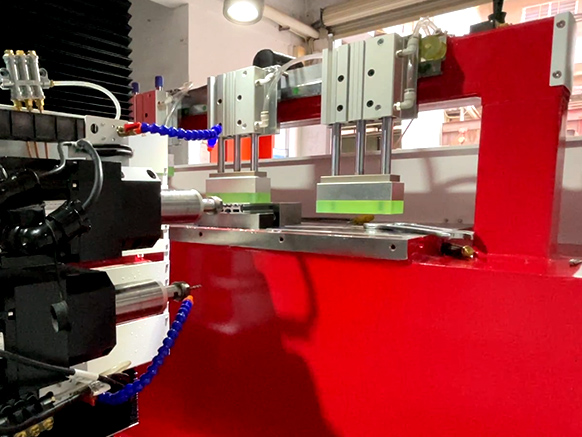

CNC Drilling & Tapping Machine

Model: DNC-1020DT

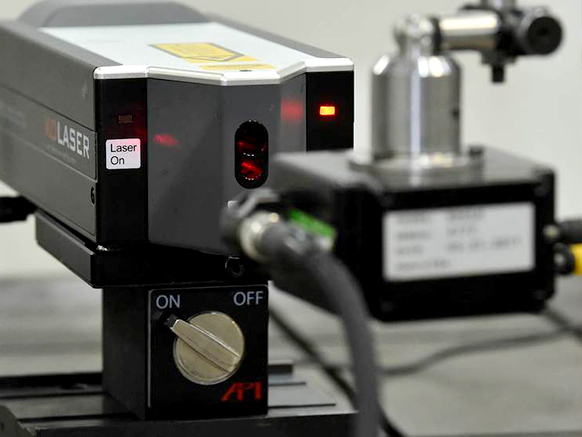

Function: Drilling & tapping

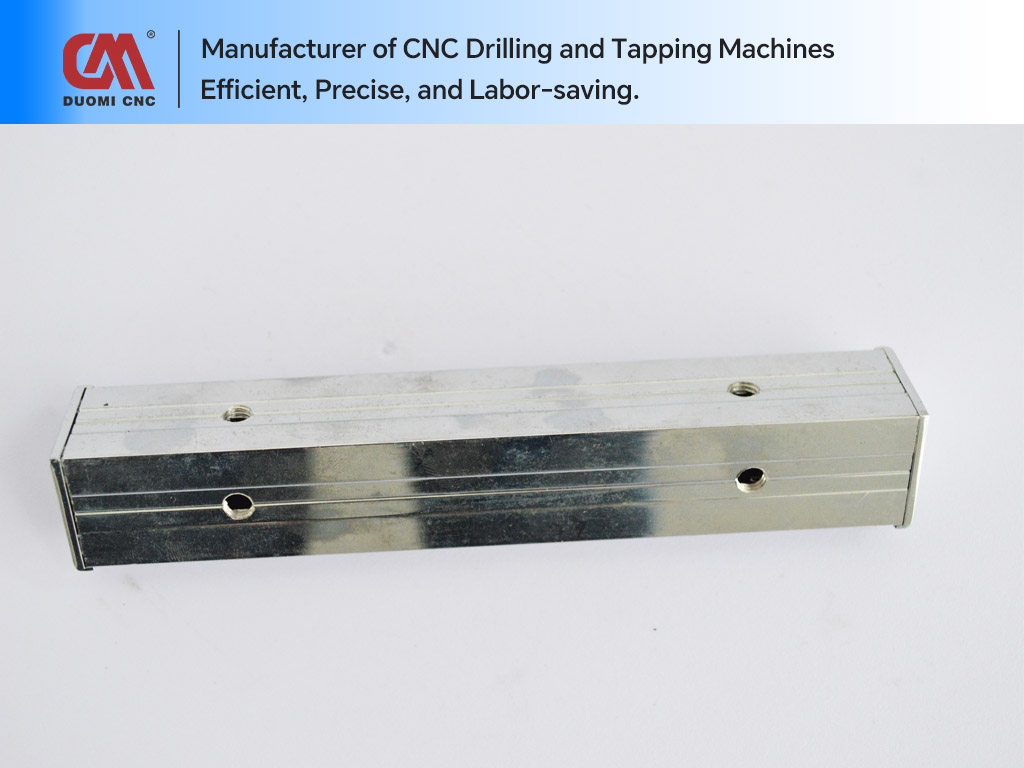

Application Materials: Iron, Copper, Aluminium, Brass, Steel, Zinc, Platinum etc.

Feature

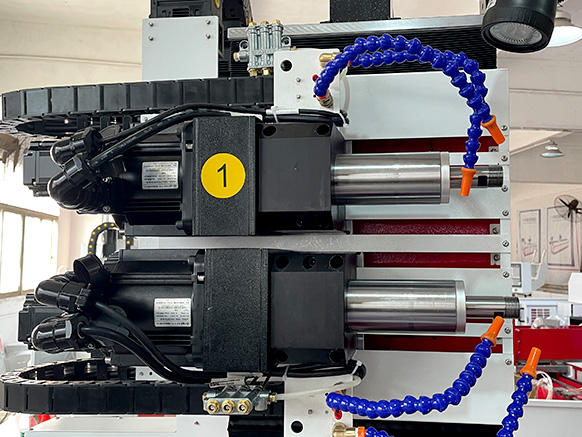

Horizontal CNC Drilling and Tapping Machine

Original Manufacturer with In-House Engineering Capability

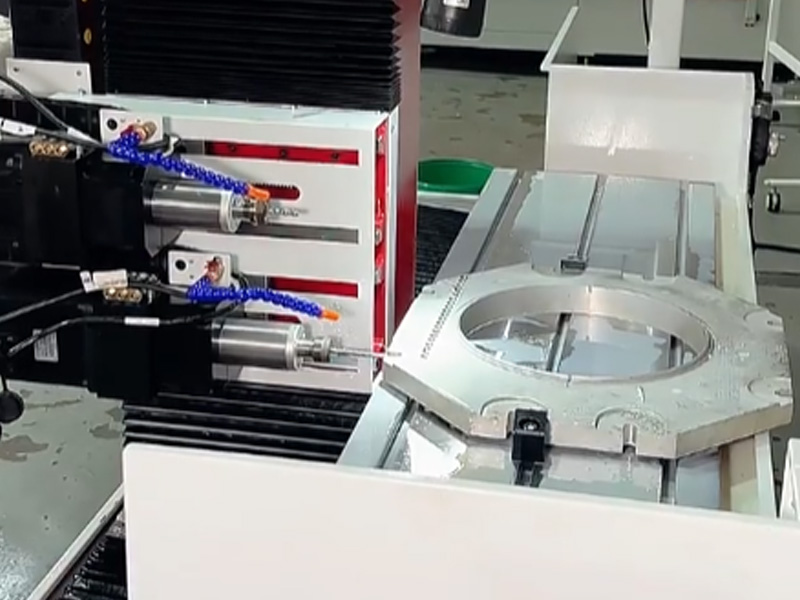

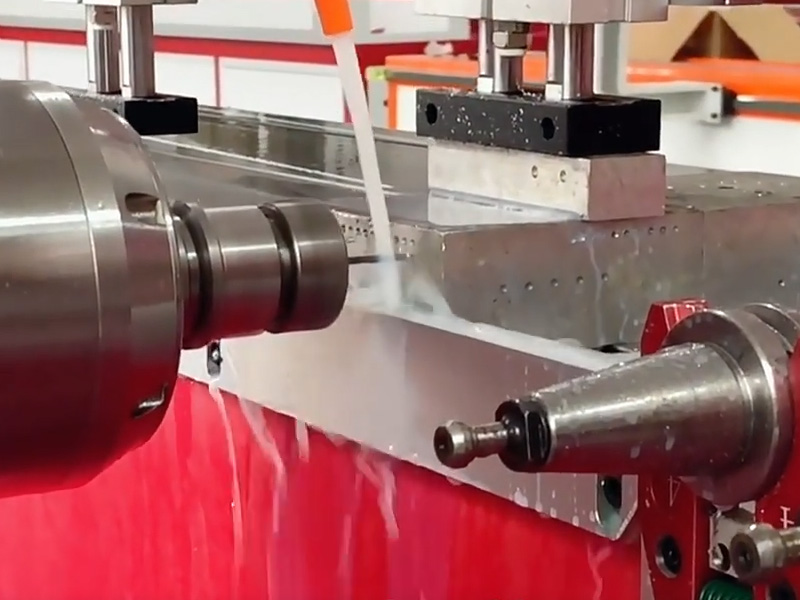

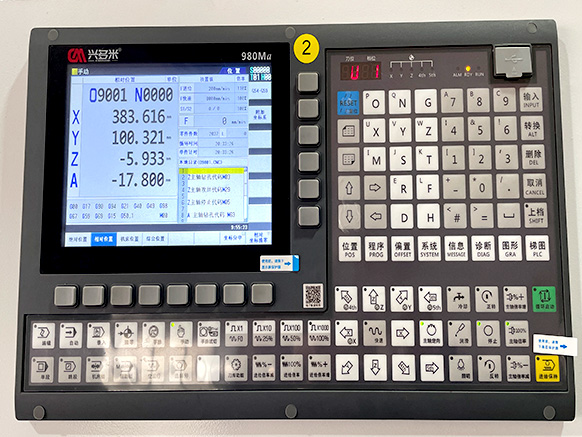

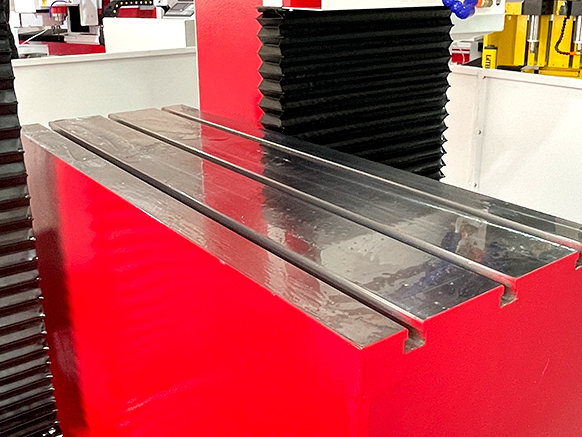

As an original manufacturer of horizontal CNC drilling and tapping machines, DUOMI CNC designs and builds equipment intended for stable, repeatable, and application-oriented machining. All core processes—from structural fabrication to system integration—are completed within our own facility, allowing consistent quality control and configuration flexibility based on customer requirements.

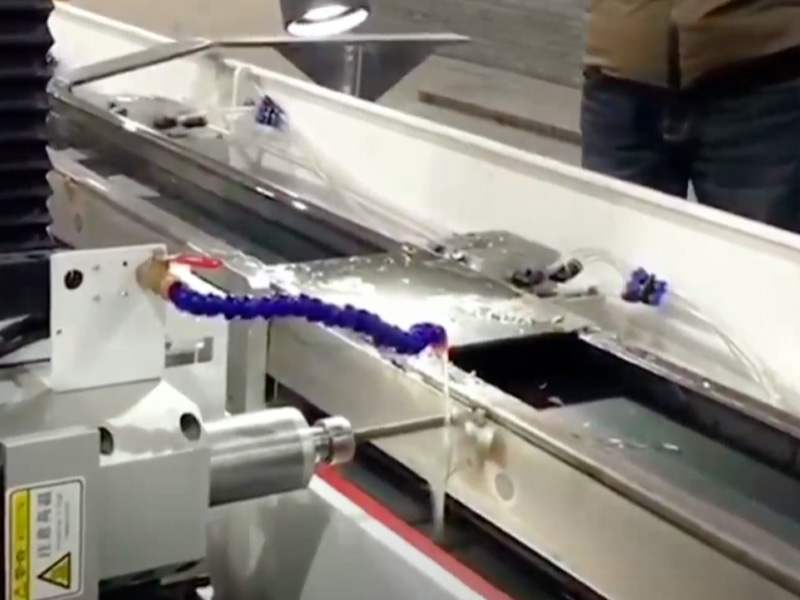

The horizontal machine architecture is developed to support efficient multi-face drilling and tapping, particularly for parts that benefit from side-entry machining, controlled chip evacuation, and rigid workpiece positioning.

Lead time (days) : 30 working days. (Standard Configuration)

Tip: Our CNC drilling and tapping machines support custom non-standard designs, machine color customization, and OEM branding. Start now to purchase and customize your own equipment, please contact us.

Request A Quote

Request A Quote