5 Steps to Choosing the Right CNC Drilling and Tapping Machine for Your Business

Learn the 5 essential steps to choosing the best CNC drilling and tapping machine for your production needs, from experts at DUOMI CNC.

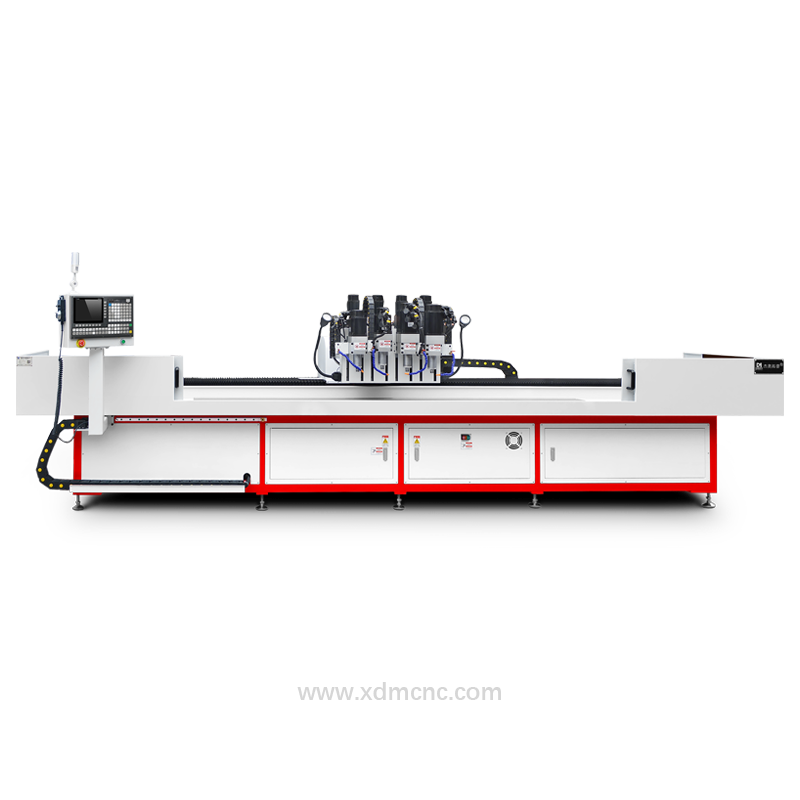

DUOMI's CNC drilling and Tapping machines Control Panel

Introduction

Choosing the right CNC drilling and tapping machine can define your factory's success. With numerous models on the market, understanding your exact production needs is key.

Step 1: Define Your Material Range

Different materials require different spindle speeds and feed rates. DUOMI CNC offers models optimized for aluminum, stainless steel, and carbon steel profiles.

Step 2: Determine Hole and Thread Requirements

High-precision threads (M3–M12) need synchronized servo spindles. DUOMI CNC machines support automatic torque detection for consistent threading depth.

Step 3: Evaluate Automation Level

If your production line demands continuous operation, consider DUOMI's automated loading system or multi-spindle configurations.

Step 4: Review Real Case Studies

A Turkish automotive accessories supplier upgraded to DUOMI's multi-axis model, reducing rework by 70%. The payback period was under one year.

Step 5: Assess Support and Maintenance

DUOMI CNC provides 24/7 global support, ensuring machine uptime exceeds 98%.

Conclusion

Selecting the right CNC drilling and tapping machine is not just a purchase—it's a strategic investment. With DUOMI CNC's global reputation and proven customer success stories, your production goals become reality.