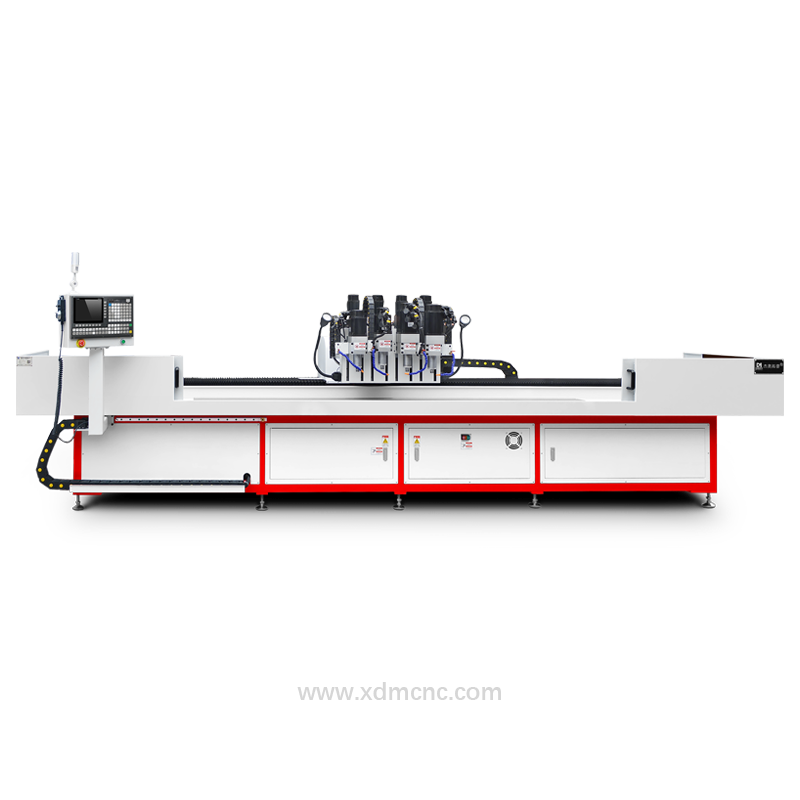

In today's manufacturing landscape, the adoption of advanced machines is critical. One standout among industrial tools is the CNC drill tap machine — offering precision, speed and versatility. From the perspective of an impartial manufacturing-consultant, we explore seven powerful advantages that make the CNC drill tap machine a strategic asset.

1. Integrated Drilling & Threading Workflow

Traditionally, drilling holes and then tapping threads were distinct operations, often using separate setups. However, a CNC drill tap machine merges drilling and tapping in a single platform, minimising repositioning and reducing cycle time. According to industry analysis, drill-tap machines handle both hole drilling and threading in one operation.

This integration leads to fewer setups, less handling and improved part-to-part consistency. For manufacturers aiming for lean workflows, the CNC drill tap machine is a game-changer.

2. Exceptional Precision & Thread Quality

When threading matters — especially in aerospace, automotive or medical components — precision is non-negotiable. The CNC drill tap machine delivers high thread accuracy thanks to its rigid tapping capabilities. Research shows that rigid tapping synchronises spindle rotation and Z-axis feed rate to cut threads with minimal error.

As a result, you achieve consistent thread pitch, tight tolerances and fewer rejected parts. This is a key reason the CNC drill tap machine is increasingly preferred for high-spec jobs.

3. Reduced Cycle Time & Higher Throughput

A major KPI in manufacturing is cycle time. The CNC drill tap machine excels here by combining operations, automating tool changes and optimising motion. For example, a vertical drill/tap center offering automation solutions reports increased productivity and efficiency.

Shorter non-cut time, faster tool changes and fewer setups mean more parts per hour, lower cost per unit and improved lead time — clear competitive advantage.

4. Versatility Across Materials & Part Geometries

Whether you are working with aluminium, steel, titanium, or complex plate structures, a modern CNC drill tap machine adapts. One supplier highlights capacity to drill Ø0.03-Ø30 mm holes and tap M3-M18 threads, on steel plates up to 220 mm thick.

From structural components to cast housings and sheet metal assemblies, the CNC drill tap machine supports a wide range of materials and shapes — helping manufacturers respond to varied production demands.

5. Automation-Readiness & Industry 4.0 Integration

In today's smart factory era, machines must do more than operate. They must integrate, monitor and optimise. The CNC drill tap machine supports automation via automatic tool changers, robotic tending, high-pressure coolant, and monitoring systems. For example, drill/tap centres now come standard with automation packages.

absolutemachine.com

Such readiness enables unmanned operations, data collection, and predictive maintenance — aligning the CNC drill tap machine with digital manufacturing strategies.

6. Longer Tool Life & Lower Maintenance Risk

Because threading is synchronised and tool motion is precisely controlled, the CNC drill tap machine reduces stresses on taps and cutting edges. The rigid tapping process reduces axial forces, minimising tap breakage and extending tool life.

JMCNCmachine

For manufacturers, fewer tool failures mean less downtime, lower tool cost and higher overall equipment effectiveness (OEE).

7. Cost Efficiency Over Life-Cycle

Although the initial investment in a CNC drill tap machine may be higher than traditional separate machines, the total cost of ownership often favors the integrated solution. Because cycle times drop, scrap reduces, labour is freed, and flexibility increases — the ROI can be compelling. For instance, the blog comparing drill/tap machines vs traditional drilling highlights long-term cost effectiveness.

Ace Micromatic Group

In summary, from precision to productivity to flexibility, the CNC drill tap machine offers unmatched benefits. If your manufacturing operation requires drilling and tapping at high volumes with quality demands, this machine should be on your radar.

Conclusion

Selecting the right equipment is critical. The CNC drill tap machine is not just a tool — it's a strategic asset for modern manufacturing. Its seven powerful advantages make it essential for companies that prioritize speed, precision, automation and cost-effectiveness. As manufacturing evolves, staying ahead means investing in the right technologies — and the CNC drill tap machine ticks all the boxes.