High-Performance CNC Drilling for Stainless Steel Discs

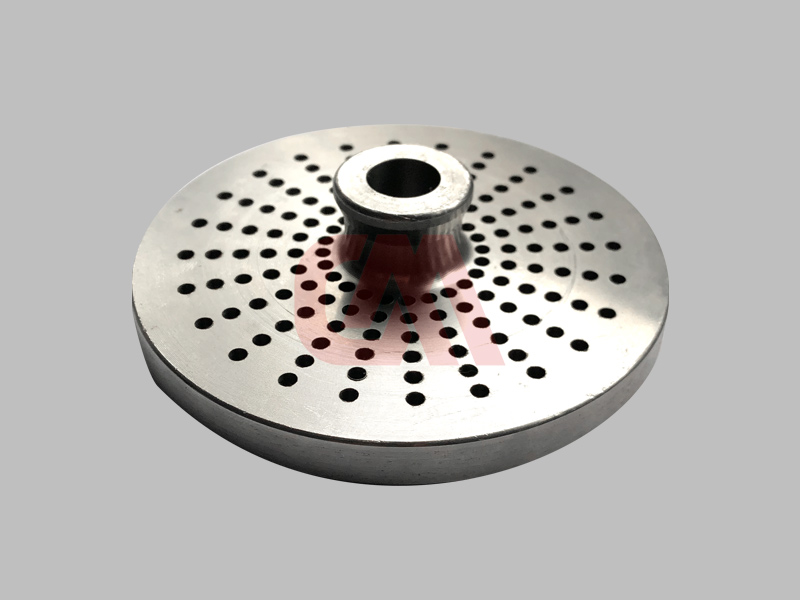

In modern precision manufacturing, the need for clean, durable, and thread-ready holes in stainless steel discs is growing rapidly — especially across industries such as automotive, food processing, energy, and industrial equipment. Traditional drilling methods often produce burrs, weak threads, or deformation when working with stainless steel. That's why DUOMI CNC's CNC drilling machine for extrusion holes in stainless steel discs has become a powerful and efficient solution for metal fabricators worldwide.

This advanced technology allows manufacturers to achieve chip-free, strengthened holes in stainless discs through a friction-based extrusion process — also known as thermal friction drilling — all controlled by CNC automation for precision and speed.

What Is Extrusion Drilling?

Extrusion drilling, sometimes called friction drilling or thermal drilling, is a chipless machining technique that uses high-speed rotation and downward force to generate heat through friction. This heat softens the stainless steel material at the drilling point, allowing the tool to form a collar or sleeve by reshaping — not removing — the metal.

When combined with a CNC drilling machine, this process becomes fully automated, repeatable, and scalable for high-volume production. The resulting holes are stronger, burr-free, and ideal for threading, especially in thin or flat stainless steel discs used in critical assemblies.

Why Use CNC Drilling for Extrusion Holes in Stainless Discs?

Stainless steel discs are used in numerous high-stress and high-precision applications. These components often require threaded holes that maintain structural integrity and sealing performance. Here's why CNC extrusion drilling is ideal:

✅ Chipless operation: No metal waste or clogging, and reduced cleaning time.

✅ Stronger threads: The extruded collar allows deeper thread engagement.

✅ No distortion: Prevents cracking or warping of thin-walled stainless discs.

✅ High precision: CNC control ensures perfect hole placement and depth.

✅ Ideal for automation: Excellent integration into robotic or multi-station production lines.

When you need both accuracy and durability in a demanding material like stainless steel, a CNC drilling machine for extrusion holes in discs is the ultimate tool.

Features of DUOMI CNC Drilling Machines

DUOMI CNC is a leading manufacturer specializing in high-performance drilling systems. Its CNC drilling machines are optimized for stainless steel materials and disc-type workpieces. Key features include:

High-speed spindle rotation up to 12,000 RPM for maximum frictional heat generation.

Drilling capacity from Ø1.5mm to Ø12mm — perfect for various disc sizes.

Custom disc clamping systems for stable and safe drilling of round parts.

Multi-head configurations for simultaneous drilling on one or more discs.

Advanced CNC control system with touch interface, real-time monitoring, and auto-feed.

Compatible with stainless grades 304, 316, duplex, and heat-resistant alloys.

DUOMI CNC machines deliver consistent quality, making them the trusted choice for global manufacturers seeking efficiency and reliability in metalworking.

Industrial Applications

The CNC drilling machine for extrusion holes in stainless steel discs is widely applied in sectors that demand precise and strong mechanical joints:

Pump and valve covers: Leak-proof threaded holes for hydraulic and pneumatic sealing.

Automotive engine components: Lightweight disc structures requiring high thread integrity.

Food machinery parts: Burr-free holes to comply with hygiene standards.

Aerospace and defense systems: Secure fastening in rotating stainless assemblies.

Energy systems: Long-life sealing and fastening in fuel cell or heat exchange units.

DUOMI CNC's extrusion drilling solution allows users to meet international quality standards while reducing production waste and cycle time.

Real-World Success with DUOMI CNC

A Korean automotive parts supplier integrated DUOMI's CNC extrusion drilling system into their stainless steel flange line. The result? A 45% increase in drilling throughput and zero tolerance failures in threaded holes, even after 100,000 fastening cycles.

Meanwhile, a German manufacturer of pump systems praised the machine's chipless performance, which eliminated costly cleaning processes in their stainless steel disc production.

Why Choose DUOMI CNC?

DUOMI CNC stands out with:

✅ Over 15 years of experience in high-precision CNC drilling

✅ Custom engineering for disc fixtures and multi-hole layouts

✅ International support and remote troubleshooting

✅ Free sample testing and project consultations

Whether you're manufacturing stainless valves, circular plates, rotary seals, or custom disc parts, DUOMI CNC offers a tailored, future-ready solution.

Take the Next Step

If you're looking to improve the efficiency, durability, and precision of your stainless steel disc drilling, DUOMI CNC's CNC drilling machine for extrusion holes is the ideal investment. Contact our team today for a free consultation, machine demo, or to request a sample part test.

Experience the next level of chipless CNC drilling — precision that powers productivity.