Boost Efficiency with a CNC Angle Drilling Machine

In the world of steel structure fabrication, power transmission towers, and angle iron processing, precision and speed are non-negotiable. The CNC angle drilling machine has become a game-changing solution for manufacturers aiming to achieve superior productivity, accuracy, and automation in drilling operations on angle steel. Whether you're dealing with high-volume tower parts or heavy-duty angle bars, this machine ensures your production stays fast, clean, and cost-effective.

In this article, we'll explore the key benefits, features, and applications of a CNC angle drilling machine, and explain why it's a must-have in modern fabrication workshops.

What Is a CNC Angle Drilling Machine?

A CNC angle drilling machine is a computer-controlled piece of equipment designed specifically for drilling holes on steel angle profiles, often used in power transmission towers, steel bridges, and telecom masts. It performs precise drilling on both flanges of the angle bar simultaneously or in sequence, guided by pre-programmed CNC data.

Unlike manual or semi-automatic drilling, the CNC system eliminates errors, minimizes labor, and ensures consistent hole alignment — crucial for bolted connections in structural assemblies.

Key Advantages of CNC Angle Drilling Machines

1. High-Speed Drilling for Large-Scale Projects

Modern CNC angle drilling machines are equipped with high-speed spindles and automatic tool changers that allow for continuous, uninterrupted drilling, even on thick angle steel. This drastically reduces processing time compared to manual or conventional machines.

For example, some advanced models can drill up to 100 holes per minute, helping manufacturers complete high-volume tower or bridge orders on tight schedules.

2. Accurate and Consistent Hole Placement

Accuracy is critical in steel structure assembly. CNC control ensures perfect alignment and repeatability of holes, even across thousands of parts. This eliminates manual measuring errors and rework, ensuring every angle bar fits precisely in its designated position.

With an accuracy of up to ±0.01 mm, CNC angle drilling machines outperform traditional setups by far.

3. Full Automation and Reduced Labor Costs

The machine operates under a fully automated CNC program. Operators simply input the drilling parameters and feed the material — the rest is handled by the machine. Advanced models come with automated feeding systems, clamping mechanisms, and chip removal conveyors, significantly reducing manpower and improving safety.

This automation can lead to a 50–70% reduction in labor costs over time.

4. Versatility Across Material Types and Sizes

A CNC angle drilling machine is not limited to one type of angle steel. It can accommodate various sizes and thicknesses, commonly from L40×40×3mm up to L250×250×35mm, and materials such as mild steel, galvanized steel, and stainless steel.

Some systems also offer marking and punching functions, turning a drilling unit into a multi-tasking production station.

5. Integration with CAD/CAM Software

Seamless integration with CAD/CAM systems allows the CNC angle drilling machine to interpret complex hole patterns directly from design files. This enhances design-to-production efficiency and minimizes setup time.

Manufacturers can upload entire tower sections and have them drilled automatically, without manual programming.

Common Applications of CNC Angle Drilling Machines

The CNC angle drilling machine is widely used across multiple industries. Typical applications include:

Power transmission towers

Telecommunication masts

Steel bridges and building frames

Solar panel supports

Railway infrastructure components

These sectors demand precision, repeatability, and volume, making CNC angle drilling systems the ideal choice.

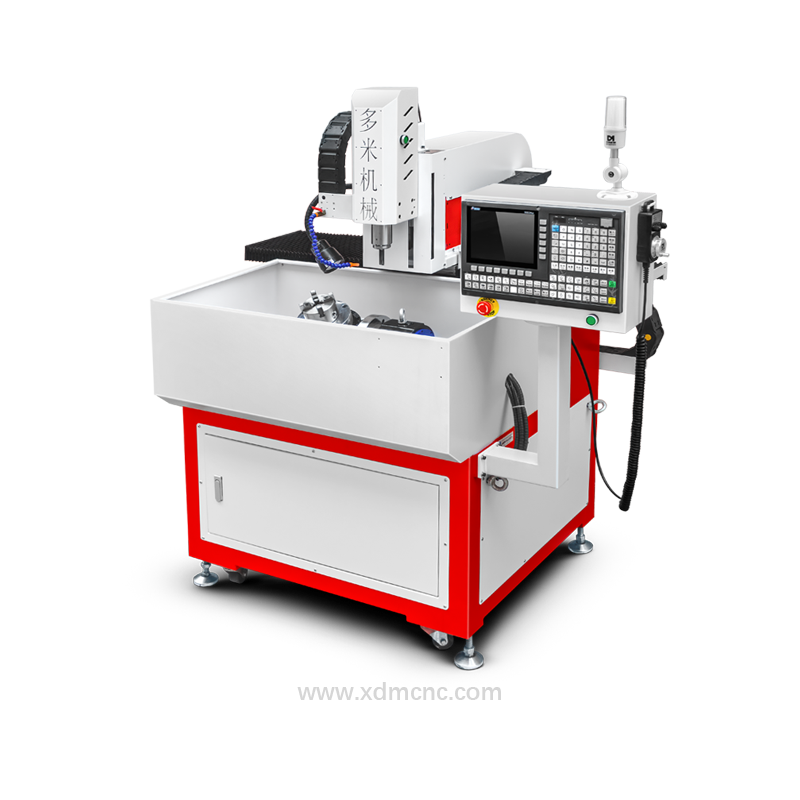

Why Choose DUOMI CNC Angle Drilling Machines?

DUOMI CNC is a trusted global brand known for advanced drilling and tapping equipment. Our CNC angle drilling machines offer:

3 or 4-axis control for flexible and complex hole patterns

Servo-driven feeding system for smooth, fast material handling

Multi-spindle heads for simultaneous drilling on both flanges

User-friendly touchscreens and intelligent programming

Strong after-sales support and remote troubleshooting

With DUOMI CNC, you're not just buying a machine — you're investing in long-term productivity and precision.

Customer Testimonials and Success Stories

A transmission tower manufacturer in India reported a 30% increase in output after adopting DUOMI's CNC angle drilling solution. Similarly, a structural steel fabricator in Southeast Asia reduced their production time by 40% and completely eliminated alignment errors.

These results prove that a CNC angle drilling machine is not just a tool — it's a competitive advantage.

Ready to Upgrade Your Fabrication Line?

If you're looking to improve accuracy, boost efficiency, and reduce labor dependency, investing in a CNC angle drilling machine is the smart choice. DUOMI CNC offers tailored solutions based on your project size, drilling volume, and automation goals.