Why Choose an Automatic Tapping Machine for Your Workshop

In today's competitive manufacturing environment, precision, efficiency, and cost-effectiveness are key to staying ahead. Whether you're producing automotive components, metal enclosures, or industrial parts, tapping is an essential step in the assembly process. That's where an automatic tapping machine comes in. Designed to automate the thread-cutting process, it delivers consistent, high-speed tapping with minimal labor and maximum accuracy.

This article explores the core advantages, features, and applications of an automatic tapping machine, making a strong case for its integration into your production line.

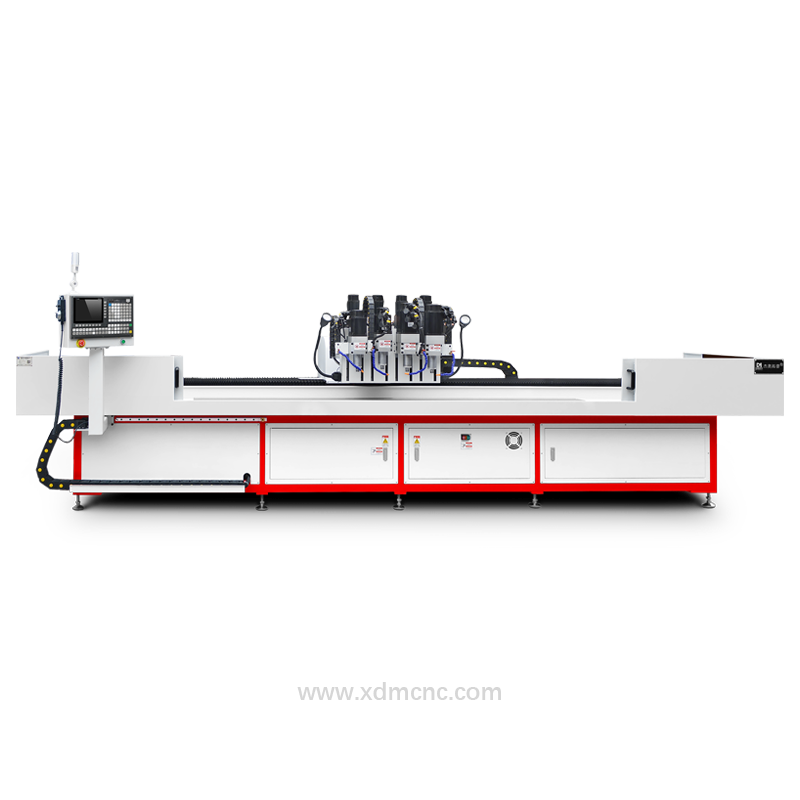

Automatic Tapping Machine

What Is an Automatic Tapping Machine?

An automatic tapping machine is a CNC or servo-controlled device engineered to cut internal threads (tapping) in pre-drilled holes on metal, plastic, or other materials. Unlike manual tapping, which relies on operator skill and time, the automatic system offers precise control, repeatability, and much faster cycle times.

These machines can be standalone units or integrated into CNC machining centers. Equipped with programmable depth control, tapping heads, and quick-change tooling, they are ideal for high-volume and multi-part production.

Key Advantages of Automatic Tapping Machines

1. Consistent Thread Quality

Manual tapping can lead to misalignment, broken taps, or inconsistent thread depth. An automatic tapping machine ensures each thread is cut with the same torque, depth, and speed — improving part quality and reducing rework.

This consistency is especially important in industries like aerospace, automotive, and electronics where tolerance is critical.

2. Increased Productivity

One of the main reasons manufacturers invest in automatic tapping machines is to increase throughput. These machines can tap hundreds of holes per hour with minimal operator intervention.

With cycle times as short as 2–3 seconds per hole, businesses experience a significant boost in output.

3. Reduced Labor Costs

Manual tapping is labor-intensive and prone to fatigue-related errors. Automatic tapping systems can be operated by a single technician and often require minimal supervision.

Over time, this translates into lower staffing requirements and reduced operational costs.

4. Compatible with Various Materials

An automatic tapping machine can handle a wide range of materials including:

Mild steel

Aluminum

Stainless steel

Brass

Plastics

This flexibility allows manufacturers to use a single machine across different product lines and industries.

5. Precision Depth Control

Equipped with servo motors and intelligent controllers, automatic tapping machines can be programmed for precise thread depth and pitch, reducing the risk of over-tapping or thread damage.

Advanced models also feature torque monitoring and automatic tap reversal to prevent tool breakage.

6. Integration with Automation Systems

Today's automatic tapping machines can be seamlessly integrated into robotic production lines or CNC machining centers. Many models come with PLC interfaces, allowing them to work in synchronized cycles with drilling, milling, or assembly stations.

This makes them ideal for Industry 4.0 smart factories focused on full automation.

Common Applications of Automatic Tapping Machines

The versatility of the automatic tapping machine makes it suitable for a wide range of applications:

Automotive parts – engine blocks, gear housings, brake systems

Electrical enclosures – threaded holes for fasteners in control panels

Furniture hardware – brackets and frames with precise screw threads

Metal fabrication – sheet metal components requiring uniform threading

Plumbing and HVAC – connectors, manifolds, and couplings

Anywhere consistent threading is required at scale, these machines provide the speed and accuracy modern production demands.

Choosing the Right Automatic Tapping Machine

When selecting an automatic tapping machine, consider the following:

Hole size and thread pitch

Material type and thickness

Production volume

Available space and integration needs

Tooling compatibility

Some machines offer multi-spindle heads, which can tap multiple holes simultaneously. Others come with automatic tool changers for different thread sizes. Choosing the right model depends on your specific production goals.

DUOMI CNC – Your Reliable Tapping Machine Partner

DUOMI CNC is a leading manufacturer of high-precision drilling and tapping systems. Our automatic tapping machines are engineered for:

Fast and precise tapping across various materials

Long tool life and easy maintenance

Seamless integration with other CNC equipment

Intelligent error detection and torque control

Customizable fixtures for specific parts and layouts

With global support, competitive pricing, and a proven track record, DUOMI CNC helps businesses achieve higher productivity with lower costs.

Request a Quote or Sample Test Today

If your production line depends on fast, accurate, and automated threading, now is the time to invest in an automatic tapping machine. Contact DUOMI CNC for a free consultation, sample processing test, or custom machine recommendation.

✅ Start tapping smarter — automate with DUOMI CNC.