Introduction: The Role of CNC in Metalworking

Metalworking has always been at the core of modern industry, powering everything from automobiles and airplanes to household appliances and fitness equipment. However, as customer demand grows for tighter tolerances, faster production, and better finish quality, traditional drilling methods are no longer sufficient.

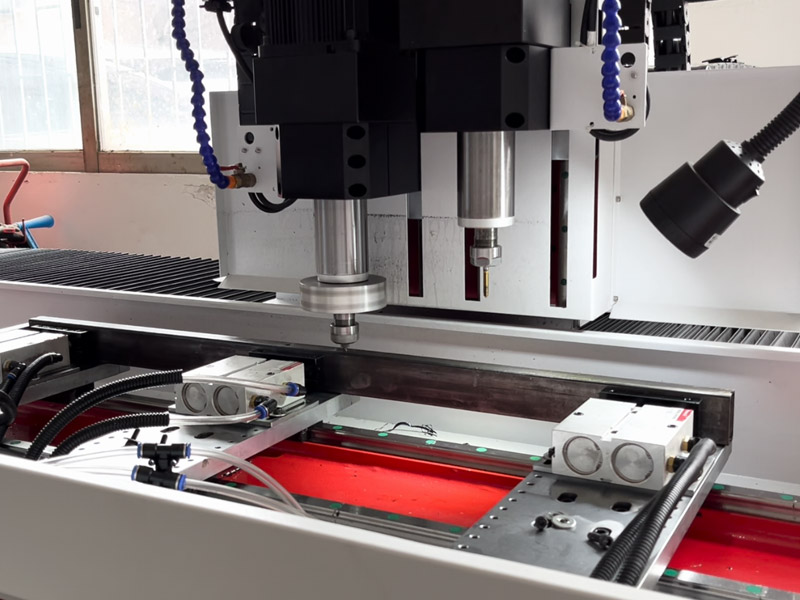

CNC Drilling Machine for Square tubes

This is where the CNC drilling machine for metal takes center stage. Unlike conventional equipment, CNC machines bring automation, precision, and scalability to the process. They are reshaping how manufacturers approach metal drilling, tapping, and forming.

Among the companies leading this revolution is DUOMI CNC, a specialist in drilling and tapping solutions with a proven track record of helping factories boost efficiency and profitability.

CNC Drilling vs. Manual Drilling – Why It Matters

To understand the value of CNC, let's compare it with traditional drilling methods:

Accuracy – Manual drilling often results in inconsistencies, while CNC drilling ensures micrometer-level precision.

Speed – Traditional drills handle one hole at a time, whereas CNC machines can drill multiple holes simultaneously with multi-spindle setups.

Operator Skill – Manual methods require highly trained workers. CNC systems minimize human error by following programmed instructions.

Flexibility – CNC machines adapt to different metals and hole types, while traditional tools often require lengthy retooling.

Scalability – Mass production is nearly impossible with manual drilling, but CNC machines thrive in high-volume manufacturing.

In short, a CNC drilling machine for metal is not just an upgrade—it's a complete transformation of how factories handle drilling.

Key Features of CNC Drilling Machine for Metal

1. Precision Drilling

Every hole is produced exactly as programmed, whether you need 0.25 mm micro-holes in stainless steel or larger structural holes in aluminum.

2. Multi-Spindle Technology

DUOMI CNC offers multi-spindle configurations that drill multiple holes at once, drastically cutting down cycle times.

3. High-Speed Capability

Modern CNC drilling machines run at high RPMs, ensuring clean finishes on tough materials like carbon steel and tungsten carbide.

4. Automated Tool Changing

DUOMI CNC machines can automatically switch between drill bits and taps, making them highly versatile for complex parts.

5. User-Friendly CNC Controls

Touchscreen interfaces and intuitive software make programming and adjustments fast and simple, even for less-experienced operators.

6. Durability for Metalworking

Built with heavy-duty frames and industrial-grade components, DUOMI CNC drilling machines handle continuous operation with minimal downtime.

Why DUOMI CNC Stands Out in the Industry

While there are many CNC brands, DUOMI CNC focuses on delivering specialized drilling and tapping solutions for metal industries.

Dedicated expertise – Years of experience producing CNC machines specifically for drilling and tapping.

Tailored models – Options for small shops needing compact machines, as well as large-scale multi-axis setups for industrial production.

Export-ready logistics – Fast delivery from Shanghai, Shenzhen, Qingdao, and Guangzhou, plus the ability to ship from any customer-specified port.

Reliable after-sales support – Worry-free warranty and technical assistance.

With DUOMI CNC, customers don't just buy a machine—they gain a long-term manufacturing partner.

Technical Breakdown: Performance You Can Trust

Hole Diameter Range: From ultra-small 0.25 mm holes to large openings for structural metal components.

Tolerance Levels: ±0.01 mm accuracy ensures consistent results.

Material Compatibility: Aluminum alloys, stainless steel, carbon steel, copper, and more.

Spindle Speed: High RPM options for different metals and applications.

Production Speed: Multi-spindle machines can boost throughput by 40–60% compared to single-spindle systems.

This level of precision and speed is what makes the CNC drilling machine for metal indispensable in modern production.

Industry Applications of CNC Drilling Machines

Automotive

From timing pulleys to engine brackets, CNC drilling ensures that automotive components meet strict safety and durability standards.

Aerospace

High-strength alloys like titanium and stainless steel require exact tolerances. CNC drilling guarantees reliability in mission-critical parts.

Electronics

Aluminum housings and stainless steel casings for electronics rely on micro-holes drilled with consistency and care.

Fitness Equipment

Gym equipment manufacturers benefit from strong, weld-free joints on steel tubes, made possible by CNC drilling and tapping.

Furniture Industry

Aluminum and steel frames need clean holes for assembly. CNC machines make production faster and more cost-efficient.

Case Studies: DUOMI CNC in Action

Furniture Tube Manufacturer – A client replaced nut welding with DUOMI CNC's thermal drilling machine, cutting production time by 30% and costs by 20%.

Automotive Supplier – By adopting a DUOMI CNC 4-axis drilling system, the factory achieved ±0.01 mm hole tolerance for aluminum pulleys.

Fitness Equipment Producer – With multi-spindle machines, a gym equipment company increased output by 45% without adding labor.

These real-world applications prove that DUOMI CNC machines deliver measurable results.

Maintenance and Durability

A CNC drilling machine for metal is a long-term investment. DUOMI CNC ensures:

Robust construction for 24/7 industrial use.

Low maintenance needs, with easy-access components.

Extended tool life, thanks to optimized spindle speed and coolant systems.

With proper care, DUOMI CNC machines can run for years with minimal downtime, maximizing ROI.

Cost-Efficiency: Why CNC Saves Money

Investing in CNC equipment may seem costly upfront, but the long-term benefits are undeniable:

Labor savings – One machine can replace multiple manual workers.

Reduced rework – Precise drilling eliminates scrap and defective parts.

Shorter lead times – Faster production means more satisfied customers.

Energy efficiency – Optimized drilling reduces energy consumption.

In fact, many DUOMI CNC customers report a payback period of just 6 to 12 months.

The Future of CNC Drilling in Metal Fabrication

Looking ahead, CNC drilling machines will continue to play a central role in Industry 4.0 manufacturing. With integration into smart factories, real-time data monitoring, and AI-driven automation, the potential is enormous.

DUOMI CNC is already preparing for this future by developing machines that integrate seamlessly into advanced production lines.

Conclusion: High-Precision Solutions with DUOMI CNC

The demand for speed, accuracy, and efficiency in metalworking will only continue to grow. Traditional drilling methods simply cannot keep up. A CNC drilling machine for metal is the modern solution that enables manufacturers to stay competitive.

DUOMI CNC delivers exactly what industries need—high-precision, reliable, and cost-efficient machines that transform the way metals are drilled and tapped. With fast global shipping from ports like Shanghai, Shenzhen, Qingdao, and Guangzhou, plus worry-free after-sales support, DUOMI CNC is the partner you can trust.

Upgrade your factory today with DUOMI CNC and discover the power of precision drilling.