Introduction: Why Efficiency Equals Profit

In the fast-paced world of modern manufacturing, the equation is simple: higher efficiency leads to higher profits. Yet many factories are still stuck with outdated manual drilling machines that slow down production, create inconsistent results, and rely heavily on skilled labor.

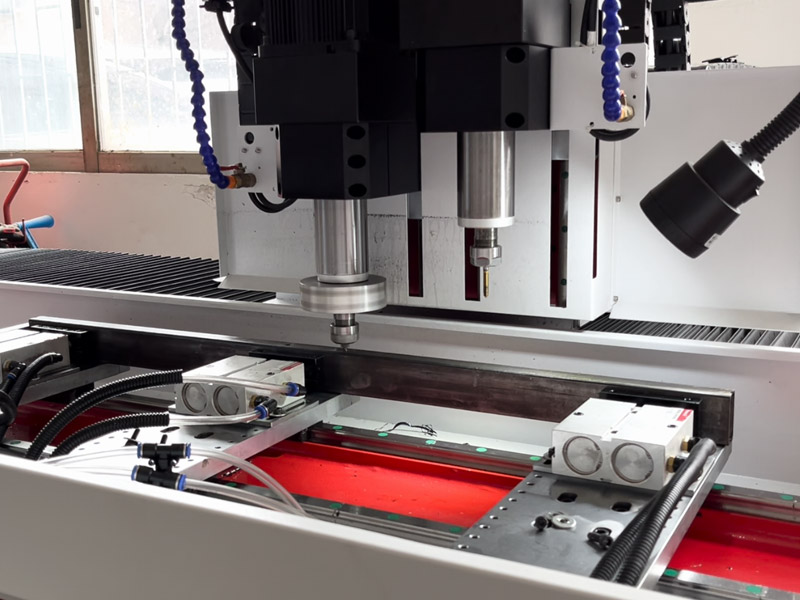

CNC drilling machine for stainless steel

The solution? A CNC drilling machine for metal. This advanced equipment not only improves accuracy but also cuts costs, reduces lead times, and increases overall profitability. Manufacturers across industries—automotive, furniture, aerospace, and fitness equipment—are discovering that upgrading to CNC technology is one of the smartest business decisions they can make.

DUOMI CNC, a trusted global supplier of CNC drilling and tapping machines, is helping companies worldwide maximize output while minimizing expenses. Let's explore how these machines deliver real business value.

The Pain Points of Traditional Metal Drilling

Before diving into solutions, it's important to understand the challenges many manufacturers face:

High labor dependency – Skilled workers are expensive and often hard to find.

Slow production speed – Manual drilling can't keep up with growing demand.

Inconsistent quality – Variations in hole size and depth lead to rejected parts.

Welding dependency – Many factories still rely on nut welding, which increases cost and lowers efficiency.

Low scalability – Traditional methods struggle with high-volume production.

These bottlenecks directly impact profitability. Every hour lost to inefficiency is money left on the table.

CNC Drilling Machine for Metal: A Smarter Business Solution

Switching to a CNC drilling machine for metal eliminates these pain points and creates measurable gains:

Automated accuracy – Every hole is drilled with perfect precision.

Higher throughput – Multi-spindle setups allow simultaneous drilling and tapping.

Labor reduction – One operator can manage multiple machines.

Flexibility – Machines adapt to aluminum, carbon steel, stainless steel, and more.

Lower costs – Less rework, less waste, and fewer welding operations.

In other words, a CNC drilling machine is not just a tool—it's a business strategy.

Why DUOMI CNC? The Brand Advantage

When choosing a CNC drilling machine for metal, brand reputation and technical support are critical. DUOMI CNC stands out for several reasons:

Specialization – Focused expertise in drilling and tapping technology.

Wide product range – From compact small CNC drilling machines to advanced 4-axis multi-station systems.

Durability – Designed for continuous heavy-duty metal processing.

Fast global shipping – Machines can be shipped from Shanghai, Shenzhen, Qingdao, Guangzhou, or any port specified by the customer.

Worry-free warranty – Reliable after-sales service ensures long-term performance.

With DUOMI CNC, you don't just buy a machine—you gain a partner committed to your business success.

Business Benefits of CNC Drilling Machines

1. Reduce Labor Costs

One DUOMI CNC machine can replace multiple manual operators. Instead of paying for skilled drilling labor, you can reallocate workers to other areas of production.

2. Increase Production Speed

CNC drilling machines complete jobs in a fraction of the time. Multi-spindle systems cut cycle times by 40–60%, which means faster order fulfillment and more revenue.

3. Improve Product Quality

Consistent accuracy means fewer defective parts. Reduced scrap and rework lead to higher customer satisfaction and repeat business.

4. Flexibility Across Industries

Whether drilling tiny holes in aluminum housings or structural holes in stainless steel frames, DUOMI CNC machines adapt quickly without costly retooling.

5. Enhance Profit Margins

By reducing expenses and increasing throughput, CNC drilling machines significantly improve profit margins.

Comparison: DUOMI CNC vs. Competitors

Many CNC machines look similar, but performance and support make the difference. Here's how DUOMI CNC leads the way:

Faster delivery – Global shipments from multiple Chinese ports.

Better ROI – Payback periods as short as 3–5 months.

Proven track record – Widely used in automotive, furniture, and fitness industries.

Comprehensive support – Technical training, installation guidance, and warranty services.

When measured against competitors, DUOMI CNC consistently offers superior value.

Industry Use Cases

Automotive Parts

Factories producing aluminum pulleys, brackets, and structural components achieve tighter tolerances and faster production with DUOMI CNC machines.

Furniture Manufacturing

CNC drilling eliminates nut welding in square steel and aluminum tubes, saving both time and cost.

Fitness Equipment

Strong, precision-drilled holes in thick steel tubes improve product durability and assembly efficiency.

Aerospace

High-strength alloys require extreme accuracy. DUOMI CNC delivers consistent results in demanding environments.

Customer Success Stories

Automotive Supplier in Asia – Reduced labor costs by 30% after switching to DUOMI CNC's 4-axis drilling machines.

Furniture Factory in Europe – Increased production output by 45% while eliminating welding processes.

Fitness Equipment Manufacturer in North America – Achieved a 25% faster delivery cycle with DUOMI CNC multi-spindle solutions.

Each success story highlights the direct link between CNC drilling technology and higher profitability.

ROI: Turning Efficiency into Revenue

Let's break down the financial impact of a CNC drilling machine for metal:

Labor savings – One machine replaces up to three operators.

Reduced rework – Defect rates drop by 80–90%.

Higher output – Faster production increases capacity.

Energy efficiency – Optimized drilling consumes less power.

For most companies, the payback period for a DUOMI CNC machine is under one year—after that, it's pure profit.

Market Trend: The Future of CNC Drilling

The demand for CNC drilling machines is expected to grow steadily as industries embrace automation. Manufacturers that adopt CNC early will enjoy a competitive edge in terms of both cost efficiency and production capacity.

DUOMI CNC is at the forefront of this trend, constantly innovating to provide smarter, faster, and more reliable drilling solutions for global customers.

Conclusion: Profits Start with DUOMI CNC

In today's manufacturing world, standing still means falling behind. Investing in a CNC drilling machine for metal is not just about upgrading equipment—it's about securing your company's future profitability.

With precision engineering, robust design, fast delivery from ports like Shanghai, Shenzhen, Qingdao, and Guangzhou, and reliable after-sales support, DUOMI CNC provides more than machines. It provides solutions that drive real business growth.

Don't wait for inefficiencies to drain your profits. Choose DUOMI CNC drilling machines for metal today and start turning efficiency into long-term success.