Industrial Metal Drill Press: 7 Reasons to Choose DUOMI CNC

If you've ever struggled with drilling metal using outdated machines, you know the frustration—slower speeds, poor hole accuracy, tool wear, and wasted labor hours. An industrial metal drill press isn't just a tool; it's the backbone of your production line. The right one can make or break your efficiency.

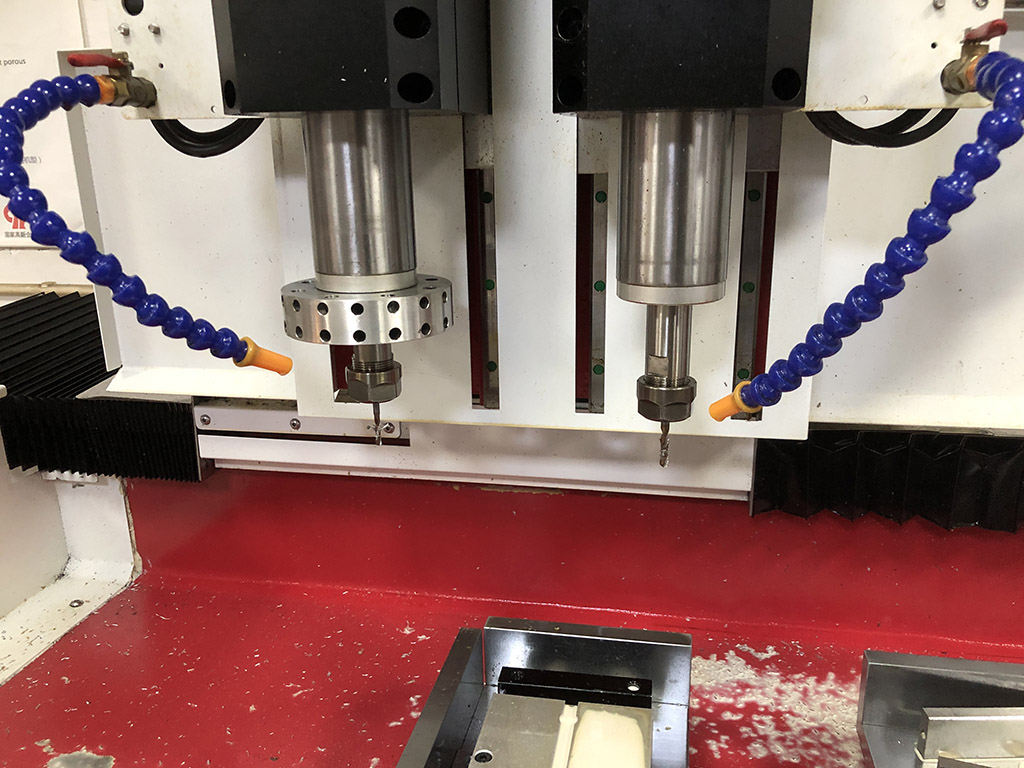

Industrial Metal Drill Press

At DUOMI CNC, we've seen manufacturers stuck with old drill presses that cause downtime and low precision. That's why we build advanced CNC drilling machines that solve these pain points head-on.

The Pain Points of Traditional Metal Drilling

Before diving into the benefits, let's talk about the problems many shops face:

Low precision – Manual drill presses often wobble and produce uneven holes.

Slow output – Traditional presses can't handle large-scale production efficiently.

High tool wear – Without CNC control, bits burn out faster, driving up costs.

Limited material compatibility – Old machines struggle with stainless steel, aluminum, and alloys.

Operator fatigue – Repetitive manual work slows productivity and increases errors.

If any of these sound familiar, it's time to rethink your setup.

Why DUOMI CNC's Industrial Metal Drill Press Is Different

Precision That Saves You Money

DUOMI CNC machines are built with advanced control systems that drill straight, accurate holes every time. No more rework or wasted raw material.

Built for Heavy-Duty Metals

Whether you're drilling stainless steel pipes, aluminum profiles, or alloy plates, our industrial metal drill press handles it with ease. That's why industries like furniture, automotive, and fitness equipment rely on us.

Faster Production Cycles

Speed matters in today's market. Our CNC drill presses reduce cycle times dramatically, letting you take on more orders without expanding your labor force.

Long Tool Life

Thanks to optimized spindle speeds and torque control, your drill bits last longer—saving you on consumable costs.

Key Features of DUOMI CNC Drill Presses

Multi-spindle options for higher output

CNC automation for minimal manual intervention

Compatibility with steel, aluminum, copper, and alloys

Energy-efficient operation to reduce overhead costs

Robust design for continuous 24/7 production

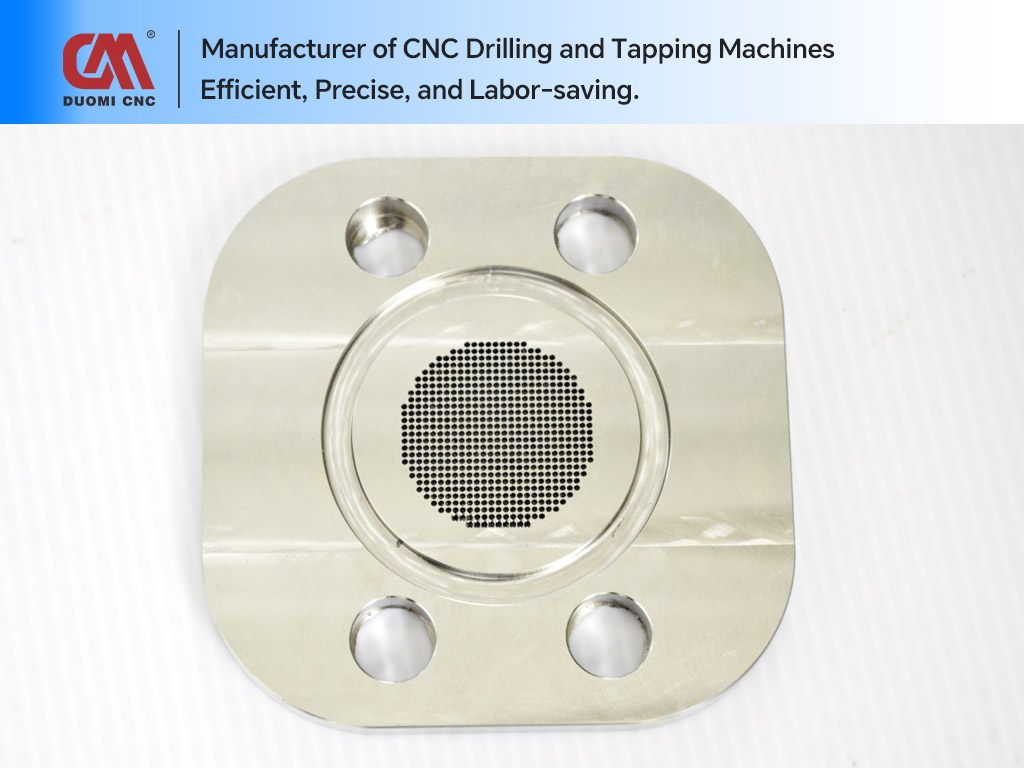

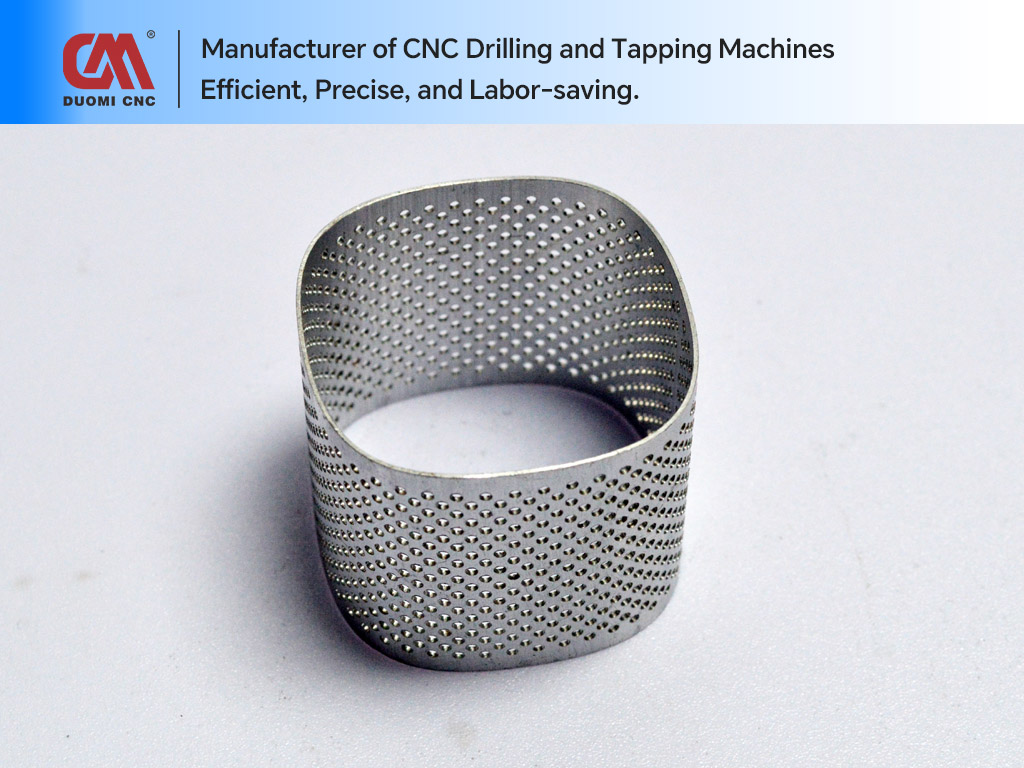

CNC Drilling and Tapping of Aluminum Filter Screens

Industrial Metal Drill Press Applications

In the Furniture Industry

Square tubes and metal frames need accurate holes for assembly. Our machines make the process seamless.

In Automotive Parts

From engine brackets to structural components, precision drilling ensures durability and safety.

In Fitness Equipment

Think about gym machines—each bolt hole matters. Our presses make drilling fast and reliable.

CNC Drilling of Aluminum Parts

Shipping and Support That Work for You

We know speed and reliability matter, especially in global trade. That's why we offer:

Shipping from major Chinese ports – Shanghai, Shenzhen, Qingdao, and Guangzhou.

Custom port options – We can deliver from any customer-specified port for convenience.

Fast delivery times – Short lead cycles so your production isn't delayed.

Worry-free warranty – Every machine comes with a hassle-free warranty and lifetime support.

When you choose DUOMI CNC, you're not just buying a machine—you're investing in peace of mind.

Why Manufacturers Worldwide Trust DUOMI CNC

Over 15 years of CNC drilling expertise

Machines installed in more than 30 countries

Tailored solutions for different industries

Factory-direct pricing that maximizes ROI

Ready to Upgrade?

If your current industrial metal drill press is holding back production, it's time for a change. DUOMI CNC offers you the tools, support, and efficiency you need to grow your business.

Don't let outdated machines slow you down. Get in touch today and discover why global manufacturers trust DUOMI CNC for precision drilling.

Discover High-Performance Industrial Metal Drill Press from DUOMI CNC. Precision, durability, and efficiency for metalworking industries. Boost productivity with advanced CNC drilling technology.