In modern manufacturing, efficiency and precision make all the difference. An industrial drill press provides the stability, accuracy, and speed that workshops and factories need to stay competitive. Unlike handheld drills, this machine is built for heavy-duty tasks, consistent performance, and long-term durability.

In this article, we'll explore 6 key reasons why businesses are upgrading to an industrial drill press, along with its main applications across industries.

What Is an Industrial Drill Press?

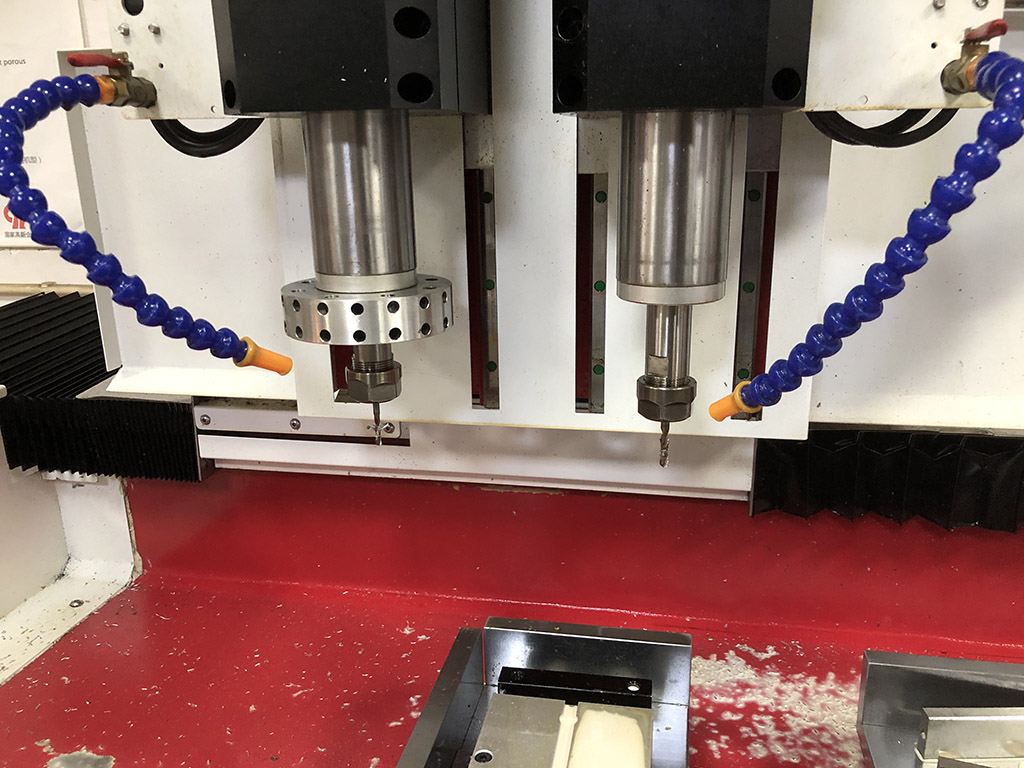

An industrial drill press is a powerful machine tool designed for drilling holes in metal, wood, and other tough materials. Mounted on a rigid base, it ensures accuracy by keeping the drill bit aligned throughout the operation. This makes it far more reliable than manual drilling methods.

6 Key Benefits of Industrial Drill Press

1. Greater Precision

An industrial drill press eliminates wobbling and misalignment, producing cleaner and more accurate holes.

2. Higher Productivity

With adjustable speeds and heavy-duty spindles, it handles multiple materials quickly, reducing cycle times.

3. Versatility Across Materials

From stainless steel to aluminum and hardwood, the machine adapts to a wide range of applications.

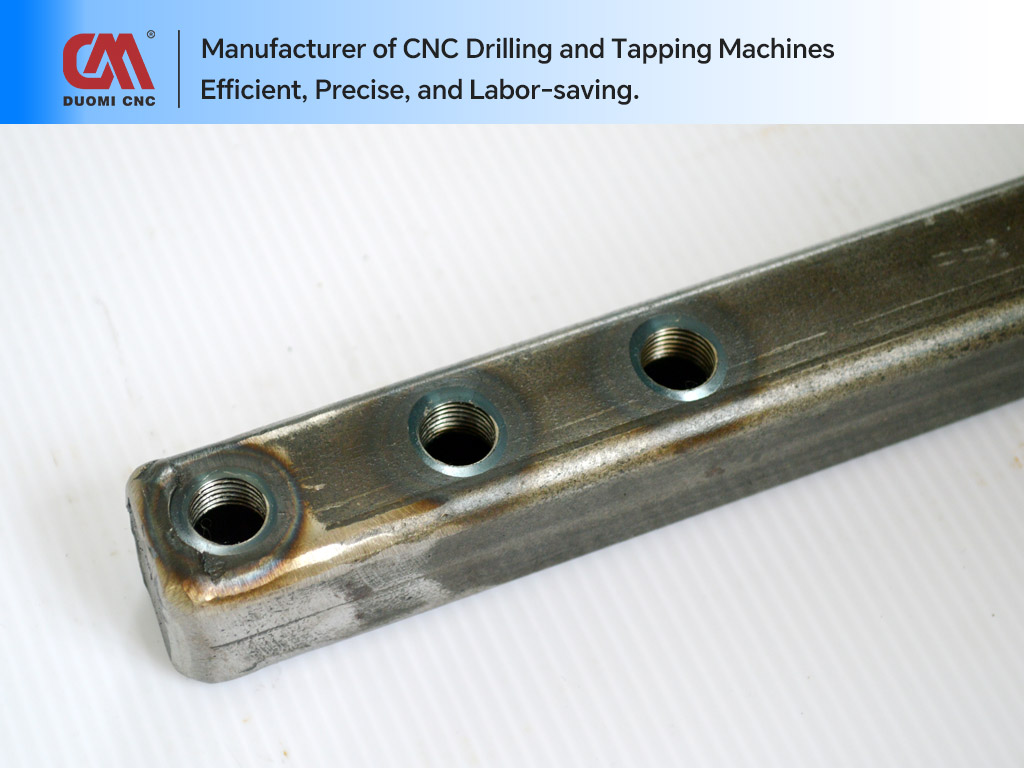

4. Consistency in Large Orders

Unlike manual drilling, an industrial drill press ensures every hole is uniform, which is critical for mass production.

5. Reduced Operator Fatigue

Since the machine provides stability, operators don't need to apply as much effort, lowering physical strain.

6. Longer Tool Life

Controlled speed and stable drilling reduce tool wear, saving costs on frequent bit replacements.

Applications of Industrial Drill Press

Metalworking

Perfect for drilling steel plates, tubes, and profiles with accuracy.

Automotive & Aerospace

Critical for drilling precision holes in components that require strength and consistency.

Construction Industry

An industrial drill press is often used for creating anchor holes, joints, and fastener points in structural materials.

Why Upgrade Now?

Traditional handheld drills can't meet the demands of modern mass production. They are slow, inconsistent, and prone to errors. By switching to an industrial drill press, you gain faster output, better accuracy, and a professional finish that builds customer trust.

Final Thoughts

For businesses serious about productivity and quality, an industrial drill press is not just an option—it's a necessity. With benefits like precision, speed, and durability, it offers the perfect balance between performance and cost savings.

Upgrade your workshop today with an industrial drill press and see the difference in efficiency and product quality.