When deadlines are tight and your shop floor is buzzing, the last thing you want is a slow, outdated process that wastes time and money. Traditional setups for drilling and tapping often force manufacturers to rely on multiple machines, extra labor, and endless setups. The result? Low efficiency, high costs, and inconsistent quality.

CNC Drill Press Tapping Machine

That's why more businesses worldwide are upgrading to a drill press tapping machine from DUOMI CNC. If you're tired of old equipment slowing you down, it's time to see how this modern solution can change your production game.

The Pain Points of Traditional Drilling and Tapping

Let's be real—every shop has experienced the headaches that come with using separate drilling and tapping machines.

Multiple Setups – Moving parts between machines means wasted minutes on every component.

Inconsistent Quality – Human error causes off-center holes and threads that don't align.

High abor Dependency – Operators spend more time adjusting than producing.

Slow Production – Traditional methods can't keep pace with high-volume orders.

Maintenance Headaches – Outdated equipment breaks down more often, costing you money.

If any of these sound familiar, you're not alone. The good news? A drill press tapping machine eliminates these problems.

What Is a Drill Press Tapping Machine?

A drill press tapping machine combines drilling and tapping into one precise, efficient process. Instead of moving workpieces between stations, you can drill the hole and tap the thread in one smooth cycle.

Precision Every Time

With CNC controls, every hole and thread is cut to exact specifications—no guesswork, no wasted parts.

Faster Production Cycles

Dual-function efficiency cuts cycle times in half and keeps orders moving out the door.

Flexible Applications

From steel and aluminum to stainless and titanium, these machines handle a wide variety of materials.

Rugged Construction

DUOMI CNC builds each drill press tapping machine with heavy-duty frames and precision spindles designed for high-volume workloads.

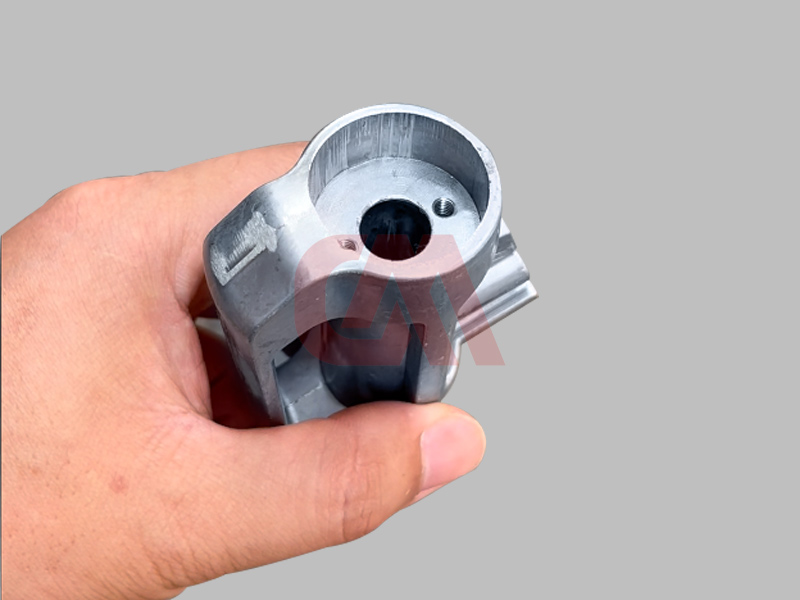

CNC drill and tap machine for Aluminum Housings of Automotive Parts

Real-World Applications of Drill Press Tapping Machines

Shops around the globe are already putting these machines to work in industries like:

Automotive – High-speed drilling and tapping in die-cast aluminum components

Furniture – Precision hole and thread machining on aluminum profiles

Aerospace – Complex drilling and tapping in titanium and specialty alloys

Fitness Equipment – Multi-hole drilling on steel tubing with accurate tapping

Electronics – Dense micro-hole drilling and threading in aluminum sheet metal

Wherever precise drilling and tapping are needed, DUOMI CNC's solution is the smarter choice.

Why Choose DUOMI CNC Drill Press Tapping Machine?

Plenty of suppliers sell machines, but only DUOMI CNC delivers the complete package.

Global Shipping Options

We ship quickly from China's major ports: Shanghai, Shenzhen, Qingdao, and Guangzhou. Need another port? No problem—delivery can be arranged based on your specific request.

Fast Delivery

We know production can't wait. That's why DUOMI CNC prioritizes short lead times to keep your operations running smoothly.

Worry-Free Warranty

Every drill press tapping machine comes with a comprehensive warranty and lifetime technical support. You'll never be left stranded.

Trusted Worldwide

Our machines are already in operation in workshops across the globe, trusted for their speed, durability, and precision.

CNC Drilling and Tapping for Die-Cast Aluminum

The Benefits You'll See Immediately

Upgrading to a drill press tapping machine delivers measurable improvements:

Up to 50% faster production cycles compared to traditional setups

30% lower labor costs with reduced manual adjustments

Fewer rejected parts thanks to CNC-driven precision

Longer machine life with DUOMI CNC's rugged engineering

Faster ROI – many customers recover their investment within months

Stand in Your Shoes – What Matters Most

Think about what you deal with daily:

Delayed shipments because of bottlenecks

Workers tied up on repetitive tasks instead of adding value

Rising labor costs with shrinking margins

The stress of knowing your equipment may not keep up with demand

A DUOMI CNC drill press tapping machine solves these problems head-on. It gives you confidence in your workflow, peace of mind in your quality, and the competitive edge your customers demand.

Why Now Is the Right Time

Markets are moving faster than ever. Customers expect quick turnaround, flawless quality, and competitive pricing. If your equipment can't keep up, you're already falling behind.

A drill press tapping machine from DUOMI CNC isn't just an upgrade—it's your pathway to staying relevant, profitable, and future-proof.

Final Thoughts

The days of struggling with old, inefficient setups are over. The drill press tapping machine from DUOMI CNC is a complete solution that doubles your productivity, slashes costs, and guarantees precision.

With global shipping from Shanghai, Shenzhen, Qingdao, Guangzhou, or any port you request, plus fast delivery and a worry-free warranty, DUOMI CNC makes upgrading easy.

If you're serious about improving your production line, it's time to invest in a machine that works as hard as you do.

DUOMI CNC – Precision You Can Trust, Productivity You Can Count On.