When you're running a business that depends on accuracy, speed, and reliability, nothing matters more than choosing the right high precision drilling machine. Whether you're working with metal tubes, aluminum profiles, or stainless steel components, even the smallest error in drilling can ruin an entire batch of products. That's exactly why manufacturers across industries are switching to advanced solutions from DUOMI CNC—a brand trusted worldwide for cutting-edge CNC drilling technology.

In this article, we'll dive into why investing in a high precision drilling machine is not just smart, but necessary for modern production. We'll highlight common pain points of traditional drilling methods, explore the long-tail benefits of precision CNC systems, and show you why DUOMI CNC is a partner that delivers global solutions with unmatched speed and reliability.

Why a High Precision Drilling Machine is a Game-Changer

Accuracy is not just a buzzword—it's the backbone of your production line. Traditional drilling equipment often comes with several pain points:

Inconsistent hole sizes that compromise product quality.

Tool wear and frequent downtime, driving up maintenance costs.

Slow cycle times that can't keep up with growing demand.

Operator fatigue and human error, especially in mass production.

When you scale these issues across thousands of parts, the hidden costs stack up quickly. That's why businesses in industries like furniture manufacturing, automotive parts, aerospace components, and fitness equipment are now searching for high precision drilling machines designed for modern demands.

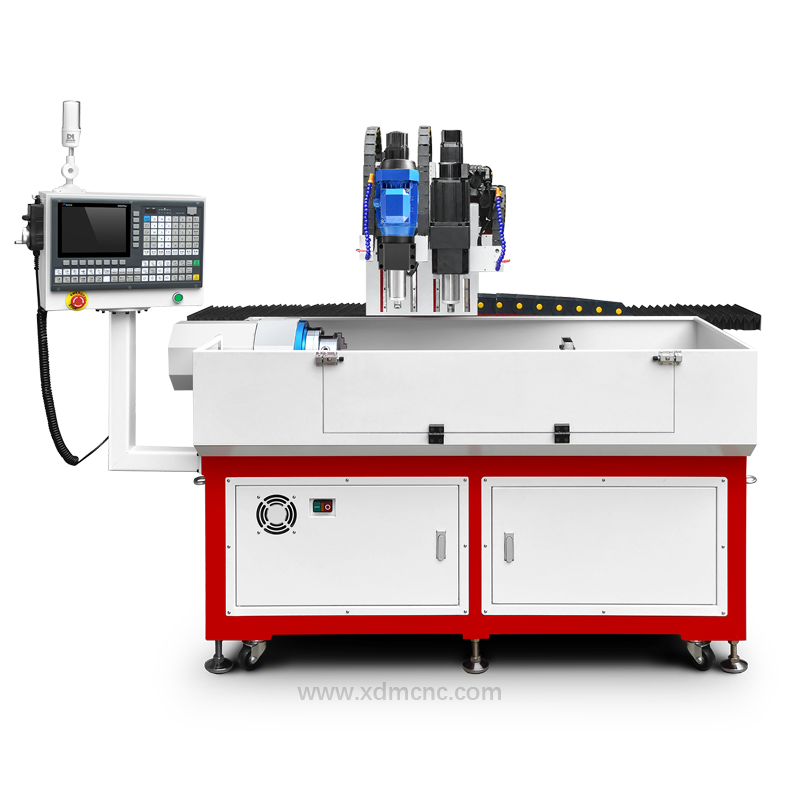

The DUOMI CNC Advantage in High Precision Drilling

Choosing DUOMI CNC means choosing a partner that understands production realities. Our high precision drilling machines combine:

Advanced CNC technology for flawless accuracy within microns.

Multi-axis control that allows complex drilling, tapping, and milling in one setup.

Durable spindles and tooling systems that extend machine life and cut downtime.

User-friendly operation panels that reduce training time and human error.

These features translate into one key benefit for you: higher productivity with fewer headaches.

Applications of High Precision Drilling Machines

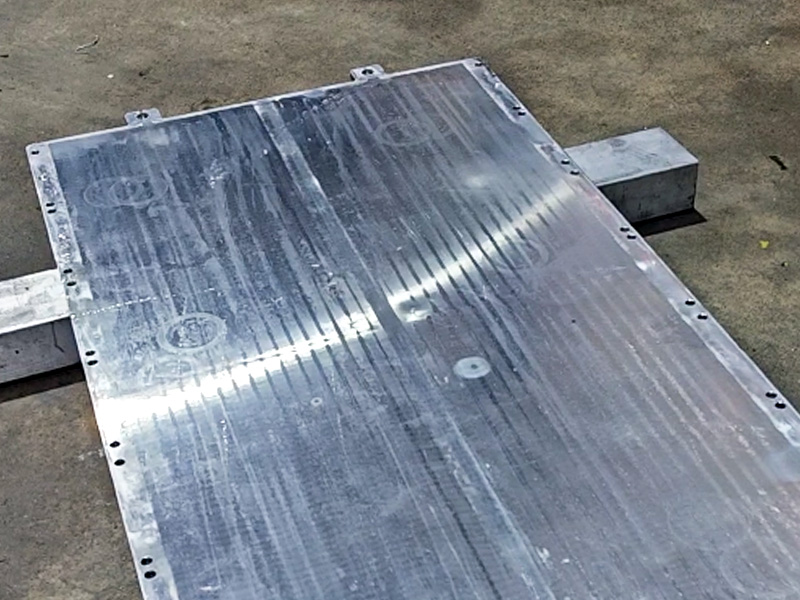

A high precision drilling machine isn't limited to one sector—it's a versatile workhorse. Some common applications include:

Square tube and round pipe drilling for furniture frames and display racks.

Thermal friction drilling and tapping in stainless steel and aluminum tubes.

Micro-hole drilling for medical devices and electronics.

Heavy-duty drilling and tapping in automotive and aerospace parts.

No matter your industry, the DUOMI CNC solution ensures your production line gets the consistency and repeatability you need to compete globally.

Long-Tail Benefits of Investing in Precision

When searching for solutions, many companies use terms like “CNC precision drilling machine for stainless steel” or “high accuracy drilling machine for aluminum profiles.” These long-tail keywords reflect real-world needs: reliability, adaptability, and cost-efficiency.

By investing in DUOMI CNC's high precision drilling machine, you're securing:

Lower reject rates, which directly boost profits.

Faster turnaround, enabling you to meet urgent client demands.

Energy-efficient designs, cutting down on production costs.

Global shipping and after-sales support, making ownership stress-free.

Hassle-Free Shipping From Major Chinese Ports

We understand that delivery time is crucial for your production schedule. DUOMI CNC provides fast and flexible shipping from multiple major ports in China, including:

Shanghai

Shenzhen

Qingdao

Guangzhou

And if you prefer another port, we can ship according to your designated port of choice. Our streamlined logistics process ensures your high precision drilling machine arrives quickly, minimizing downtime and getting your line moving as fast as possible.

Warranty and After-Sales Peace of Mind

Buying industrial equipment is a big investment, and we know you want long-term assurance. That's why DUOMI CNC provides:

Worry-free warranty policies covering key machine components.

Fast-response technical support for troubleshooting.

Readily available spare parts to minimize downtime.

With us, you don't just buy a machine—you get a reliable partner committed to your success.

Why Customers Trust DUOMI CNC

Global clients who have switched to DUOMI CNC often highlight:

Consistent drilling precision across thousands of parts.

Reduced manpower costs thanks to automation.

Scalability, allowing small workshops and large factories alike to expand production.

Proven durability, ensuring machines run smoothly for years with minimal maintenance.

This trust didn't come overnight—it comes from years of dedication to building world-class high precision drilling machines.

Final Thoughts: Your Next Step Toward Precision

If you've been struggling with the limitations of traditional drilling setups—slow speeds, inconsistent quality, and constant maintenance headaches—it's time to make a change. A high precision drilling machine from DUOMI CNC offers the perfect balance of technology, performance, and reliability.

With flexible shipping from ports like Shanghai, Shenzhen, Qingdao, and Guangzhou, fast delivery times, and a worry-free warranty, there's no reason to wait.

Take the first step today. Contact DUOMI CNC to explore how our high precision drilling solutions can unlock higher productivity and profits for your business.