In today’s fast-paced manufacturing industry, efficiency and precision are paramount. One of the most demanding applications is drilling small, accurate holes in rubber sheets, a task that requires both High-Speed CNC Drilling technology and specialized equipment like a Rubber Sheets Drilling Machine. DUOMI CNC offers state-of-the-art solutions to meet these challenges, combining speed, precision, and reliability for industrial applications worldwide.

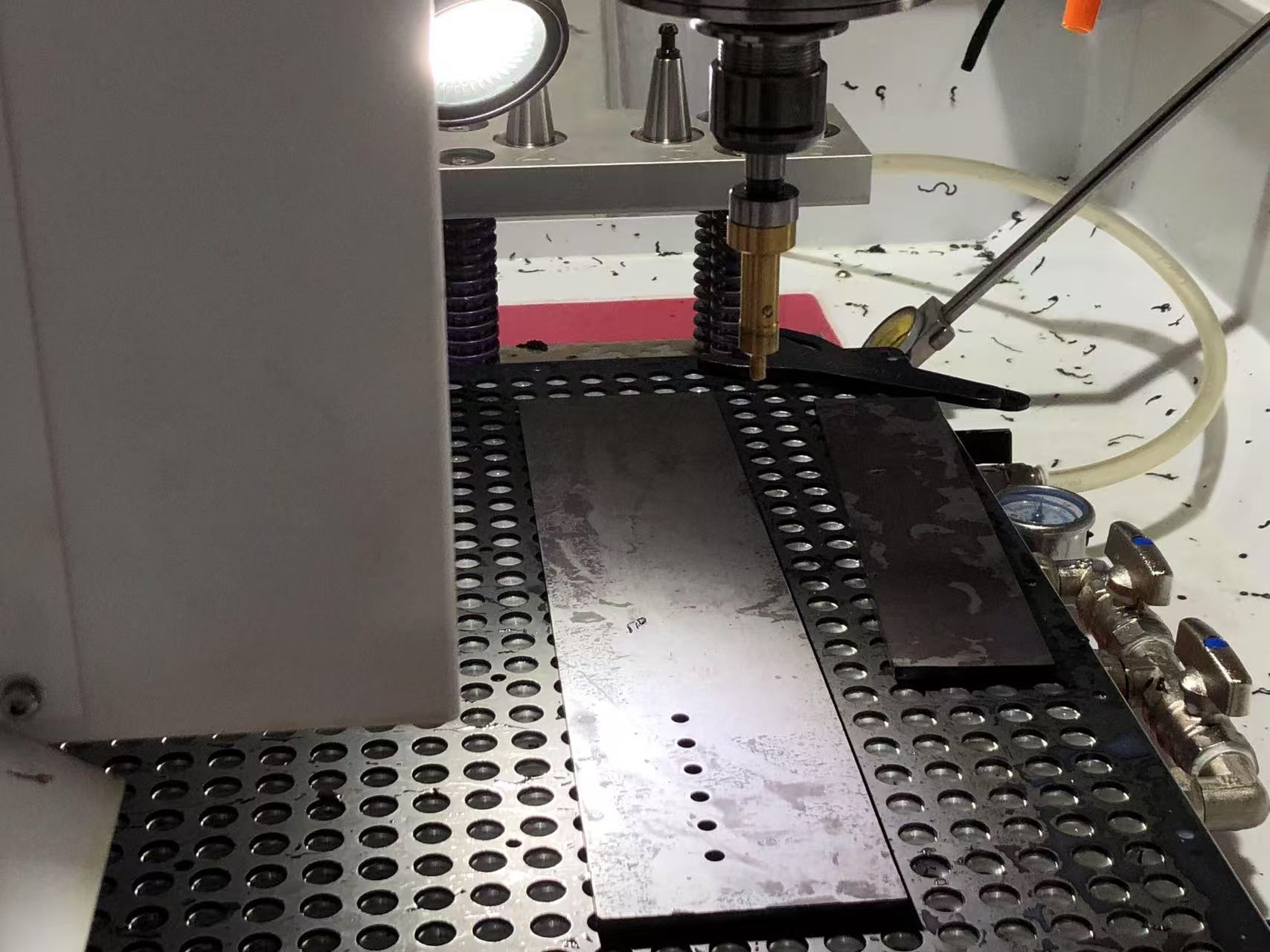

Rubber Sheets CNC Drilling Machine

1. The Challenges of Drilling Rubber Sheets

Drilling rubber sheets might seem simple, but in reality, it presents unique challenges:

Elasticity of Rubber: Rubber is highly flexible, making it prone to tearing or deformation during conventional drilling.

Hole Size Accuracy: Small holes, such as 3mm in diameter, demand extreme precision to ensure functional integrity.

Production Speed: In industrial settings, efficiency is crucial; manual drilling or traditional machines cannot maintain the required throughput.

Clean Cuts: Rubber tends to leave burrs and uneven edges if drilled improperly, affecting both product quality and downstream assembly.

These challenges highlight the need for advanced CNC technology. A Rubber Sheets Drilling Machine equipped with High-Speed CNC Drilling capabilities can deliver precise, clean holes efficiently, minimizing material waste and labor costs.

2. Advantages of High-Speed CNC Drilling for Rubber Sheets

2.1 Precision and Accuracy

With High-Speed CNC Drilling, each 3mm hole can be drilled to exact specifications with minimal deviation. DUOMI CNC machines achieve precision levels up to 0.01mm, ensuring that every hole aligns perfectly with design requirements. This is especially critical in industries like automotive, electronics, and industrial gaskets where even minor deviations can lead to failures.

2.2 Enhanced Production Speed

A Rubber Sheets Drilling Machine with high-speed capabilities drastically reduces processing time. Traditional manual or semi-automatic methods may take minutes per hole, but a DUOMI CNC solution can drill hundreds of holes per hour without sacrificing quality. This boost in efficiency allows manufacturers to meet tight deadlines and scale production effortlessly.

2.3 Minimal Material Deformation

High-speed CNC drilling reduces heat generation and friction during the drilling process. This is particularly important for rubber sheets, as excessive heat or pressure can distort the material. By maintaining consistent speed and feed rates, DUOMI CNC machines produce clean, round holes with minimal burrs, preserving the integrity of the sheet.

2.4 Automation and Ease of Operation

Modern Rubber Sheets Drilling Machines feature intuitive control systems, allowing operators to program drilling patterns without extensive training. Even complex layouts with multiple 3mm holes can be executed automatically, reducing human error and labor requirements.

3. Key Applications of Rubber Sheets Drilling Machines

Industries that benefit from High-Speed CNC Drilling on rubber sheets include:

Automotive: Gaskets, seals, and vibration-dampening components often require precise small holes.

Electronics: Rubber insulators and protective layers need exact perforations for mounting or heat dissipation.

Industrial Manufacturing: Conveyor belts, cushioning pads, and rubber grommets require uniform holes for assembly and performance.

Medical Devices: Rubber components used in medical equipment must maintain both precision and cleanliness.

By implementing a Rubber Sheets Drilling Machine, manufacturers can ensure consistent quality, high throughput, and minimal waste, meeting strict industry standards.

4. Features of DUOMI CNC Rubber Sheets Drilling Machines

4.1 Customizable Drilling Patterns

DUOMI CNC machines allow full customization of drilling layouts. Operators can program exact spacing, depth, and number of holes, enabling flexible production for various rubber sheet sizes and applications.

4.2 Multi-Spindle Configuration

Many DUOMI CNC models feature multi-spindle setups, allowing simultaneous drilling of multiple holes. This significantly increases productivity and is ideal for high-volume production environments.

4.3 High-Speed Motors and Tooling

Equipped with advanced high-speed spindles, these machines can drill 3mm holes rapidly without compromising accuracy. High-quality tooling minimizes wear and ensures long-term reliability.

4.4 User-Friendly Interface

DUOMI CNC’s software is designed for ease of use. Operators can quickly load designs, adjust drilling parameters, and monitor production in real time. This reduces the learning curve and maximizes operational efficiency.

5. Benefits of Using DUOMI CNC for Rubber Sheet Drilling

Consistent Quality: Every hole drilled meets strict tolerance requirements.

Reduced Production Costs: Less material waste and reduced labor costs through automation.

Scalability: Easily adjust production volume without sacrificing quality.

Versatility: Suitable for various rubber types and thicknesses, accommodating diverse industrial applications.

Global Support: DUOMI CNC provides worldwide technical support and after-sales service, ensuring smooth operation for international clients.

6. Why High-Speed CNC Drilling is Essential for Rubber Components

The modern manufacturing environment demands speed, precision, and reliability. High-Speed CNC Drilling combined with specialized Rubber Sheets Drilling Machines addresses all these requirements:

Efficiency: Faster drilling reduces bottlenecks in production lines.

Precision: Small 3mm holes are drilled with uniform accuracy.

Reliability: Automation reduces human error and ensures consistent output.

Material Protection: Maintains the integrity of rubber sheets, preventing tearing or deformation.

By integrating DUOMI CNC machines into production, manufacturers can optimize both quality and throughput, gaining a competitive advantage.

7. Conclusion

Drilling small holes in rubber sheets is no longer a challenge with DUOMI high-speed CNC drilling machines. Designed for precision, speed, and reliability, these machines offer a perfect solution for industries that require high-quality 3mm holes with minimal material deformation. Whether in automotive, electronics, or industrial manufacturing, a Rubber Sheets Drilling Machine from DUOMI CNC ensures consistent performance, reduced production time, and improved product quality.

For manufacturers seeking to upgrade their drilling capabilities, investing in a DUOMI CNC solution means enhanced productivity, superior accuracy, and reliable performance for every rubber sheet application.