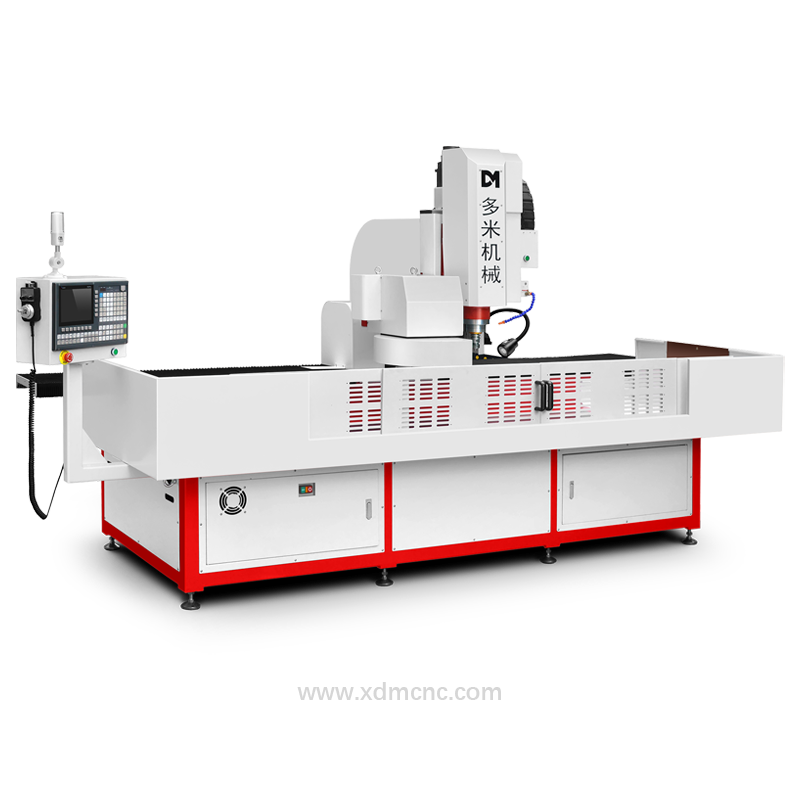

Precision Manufacturing for Diving Oxygen Cylinders: How Thermal Friction Drilling and Tapping Machines Elevate Safety and Reliability

Essential Deep-Diving Scuba Tank Equipment

In the global diving equipment industry, Diving Oxygen Cylinders represent one of the most safety-critical products ever manufactured. From recreational scuba diving to professional deep-sea operations, these cylinders must withstand extremely high internal pressure, corrosion from saltwater, and decades of rough usage. Achieving this reliability depends heavily on the precision of every threaded connection on the cylinder body, particularly the mounting holes used for valves, brackets, gauges, and auxiliary fittings.

Traditional drilling and tapping often struggle with thin-wall metals found in diving cylinders—usually high-strength aluminum alloys or stainless steel. This is where Thermal Friction Drilling and Tapping technology becomes an essential manufacturing upgrade. Compared with conventional machining, friction drilling forms a stronger, longer, and more durable internal thread—without cracking or weakening the material.

Today, manufacturers worldwide are shifting toward specialized equipment such as the Friction Drilling and Tapping Machine and the Thermal Friction Drilling Machine to meet increasingly strict quality standards. These machines deliver precision, repeatability, and structural integrity that traditional methods simply cannot match.

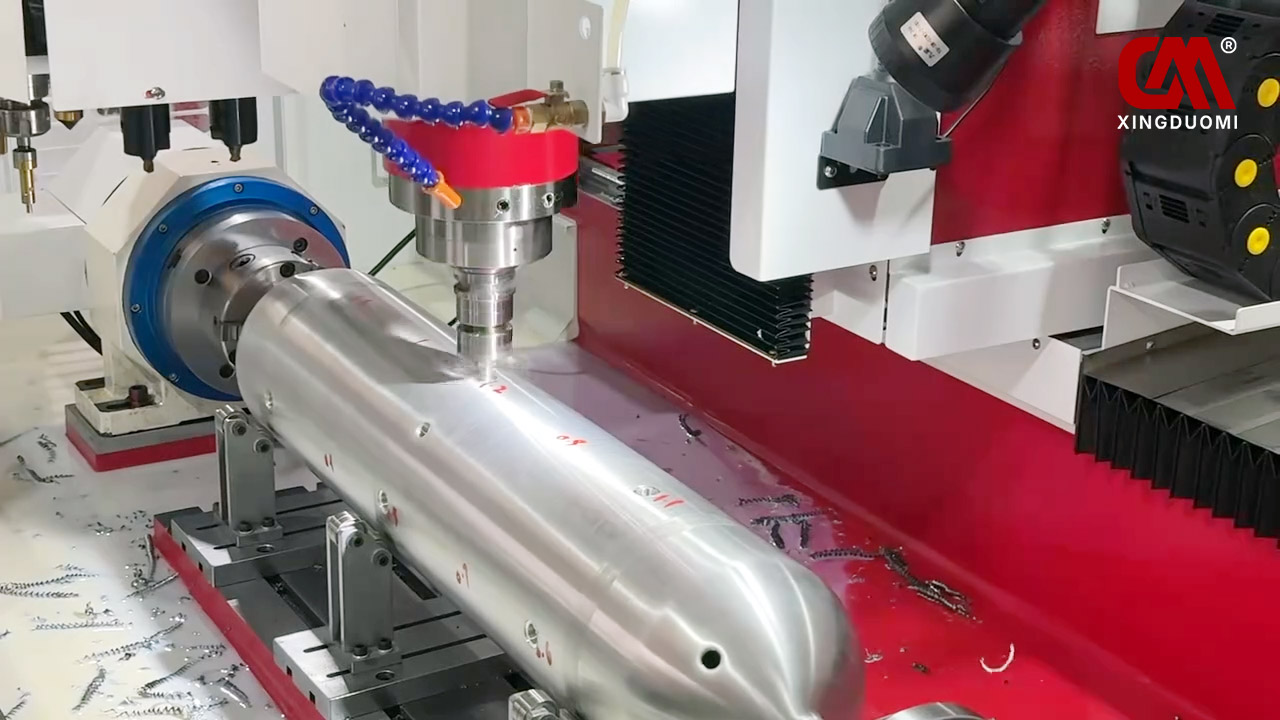

Real shot of hot tapping a scuba cylinder

1. Why Diving Oxygen Cylinders Require Extreme Manufacturing Precision

A Diving Oxygen Cylinder faces unique and unforgiving environments:

High Internal Pressure

Most cylinders operate between 150 to 300 bar (2200–4400 psi). Any threaded connection that fails can cause catastrophic leakage or explosion.

Exposure to Saltwater

Seawater accelerates corrosion, especially around drilled holes and threads.

Thin-Wall High-Strength Materials

Diving cylinders often use:

6061-T6 and 7075 aluminum alloy

Stainless steel 304/316

Chromoly steel

The challenge lies in drilling strong threads into thin walls without weakening the material.

Strict International Standards

Products must comply with:

EN 250

ISO 12245

DOT/TC regulations

Any inconsistency in drilling or tapping may cause immediate rejection in quality control.

Because of these challenges, manufacturers increasingly rely on Thermal Friction Drilling and Tapping to ensure hole integrity, extended thread length, and long-term sealing performance.

2. How Thermal Friction Drilling Works on Diving Oxygen Cylinders

Unlike traditional cutting-based machining, Thermal Friction Drilling uses high rotational speed and pressure to generate localized heat, softening the material and forming a bushing-like extrusion. This process allows even a thin-wall cylinder to obtain a longer and stronger threaded connection.

Key Advantages for Cylinder Manufacturing

(1) Stronger Thread Formation

The process extrudes material instead of removing it, increasing the thread engagement length by up to 300%.

This is vital for components such as:

Valve mounting holes

Gauge interfaces

Pressure regulator attachments

(2) No Burrs, No Cracks

The high-speed thermal process eliminates burr formation and prevents micro-cracks common in hard metals.

(3) No Need for Inserts or Welding

Traditional cylinder fabrication often uses welded nuts or threaded inserts.

Friction drilling eliminates these weak points, reducing manufacturing cost and improving structural reliability.

(4) Perfect for Thin-Wall Tubes

Diving cylinders are typically 3–7 mm thick—ideal for friction drilling's material-forming advantages.

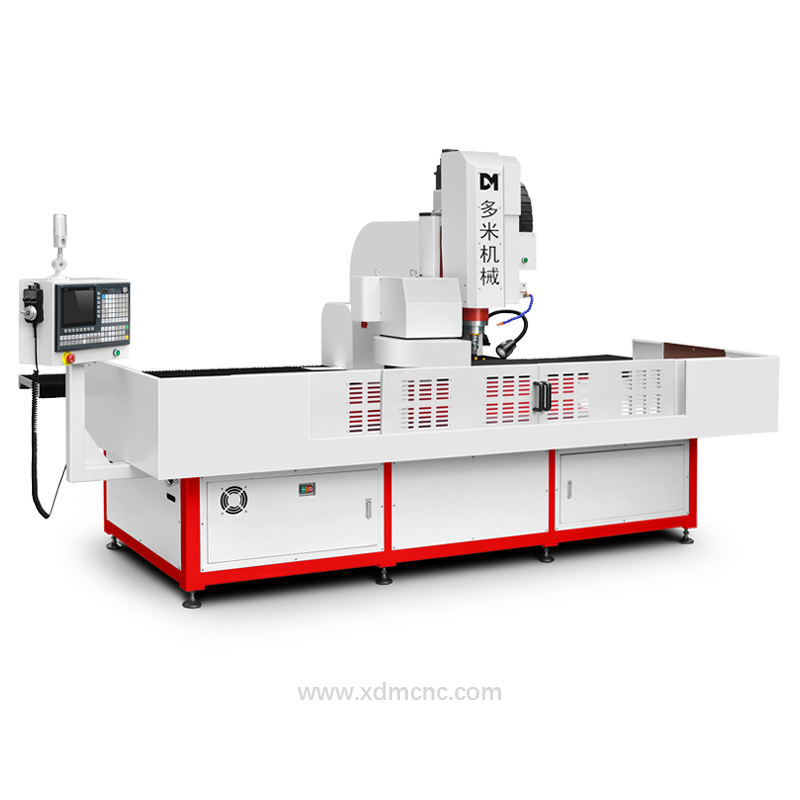

3. Why Choose a Dedicated Friction Drilling and Tapping Machine

While many CNC drilling machines can perform basic drilling, Diving Oxygen Cylinder production requires a specialized machine engineered for:

(1) High-Temperature Stability

Thermal Friction Drilling generates significant localized heat.

A dedicated Thermal Friction Drilling Machine includes:

Heat-resistant spindles

Reinforced bearings

Precision coolant systems

(2) Ultra-High Spindle Speeds

Friction drilling requires 2000–8000 rpm depending on material hardness.

A standard CNC drill may not reach such speeds efficiently.

(3) Integrated Servo Tapping

Once the hole is thermally formed, tapping must follow immediately at controlled torque and pitch accuracy.

(4) Rotary Fixtures for Cylindrical Parts

Diving cylinders require perfect hole alignment along curved surfaces.

A specialized machine includes:

Custom clamps

Rotating positioning fixtures

Multi-axis precise alignment

(5) Repeatability and Quality Traceability

Modern friction drilling systems include CNC programming, production logs, and auto-compensation features—ideal for ISO-certified mass production.

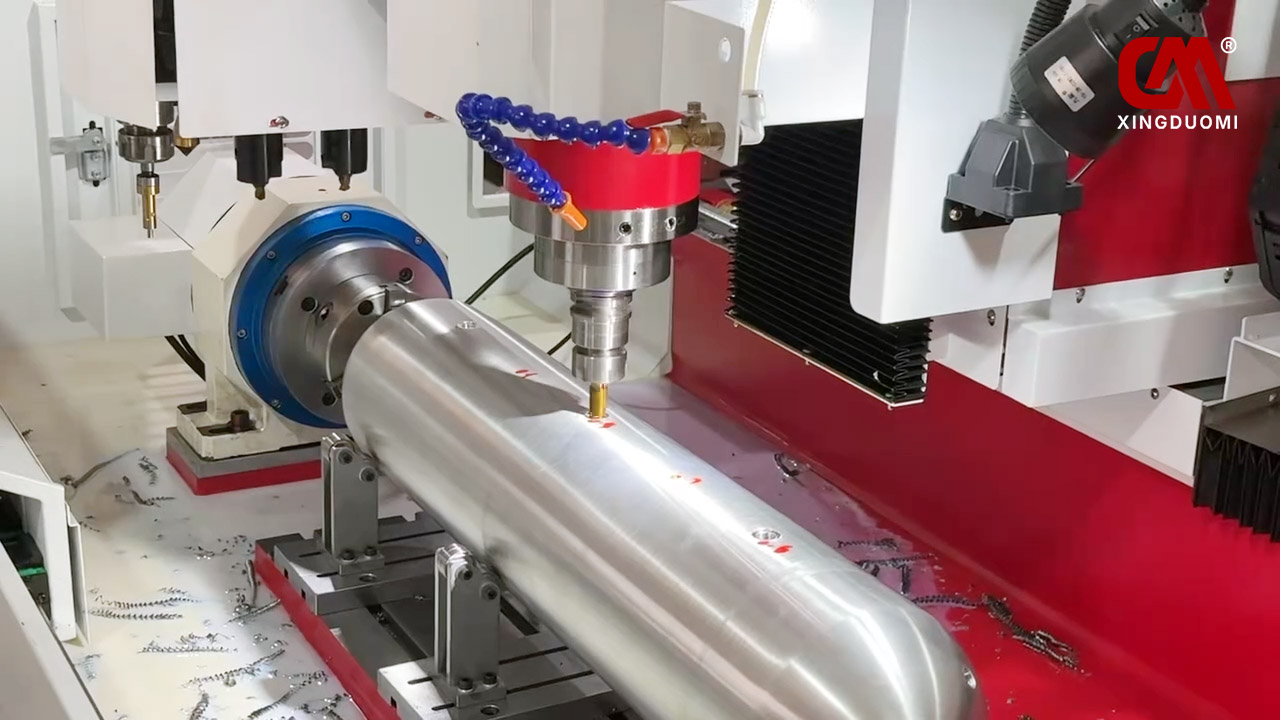

Real-life image of hot-tap drilling on a scuba tank valve

4. Application Scenarios of Thermal Friction Drilling on Diving Oxygen Cylinders

Valve Port Holes

Ensures long-lasting thread engagement for high-pressure air valves.

Transport Handle Mounting

Provides secure, vibration-resistant thread formation.

Gauge & Pressure Sensor Ports

Leak-free threaded connections are vital for divers’ safety.

Bracket & Strap Attachments

Prevents cracking when the cylinder is repeatedly secured by straps.

Auxiliary Accessories

Such as lights, identification tags, or underwater equipment mounts.

Every hole must deliver high precision and high mechanical strength—exactly what friction drilling provides.

5. Production Benefits for Cylinder Manufacturers

Reduced Production Steps

No pre-drilling, no deburring, no welding of nuts.

Lower Scrap Rate

The process minimizes cracking and deformation.

Better Sealing Performance

Stronger threads reduce long-term air leakage risks.

Significant Labor Savings

Fully CNC-controlled operations ensure automation and stable quality.

Higher Safety Compliance

Friction-drilled holes naturally meet or exceed regulatory requirements due to enhanced structural integrity.

6. Why More Manufacturers Prefer Dedicated Thermal Friction Drilling Machines

Modern manufacturers choose specialized equipment because it offers:

Faster cycle times

Consistent quality across thousands of cylinders

Higher precision with no manual errors

Lower long-term maintenance cost

Greater safety assurance for end users

The technology is becoming a new standard within the diving equipment manufacturing industry.

Must-Have Scuba Cylinder Setup for Deep-Sea Diving

Conclusion

As the demand for high-performance Diving Oxygen Cylinders continues to grow, so do the requirements for precision manufacturing. Thermal Friction Drilling and Tapping technology provides unmatched structural strength, consistency, and reliability—making it the preferred solution for producing safe, durable, and compliant cylinders.

Manufacturers using a dedicated Friction Drilling and Tapping Machine or Thermal Friction Drilling Machine gain a significant competitive advantage through improved quality and reduced production costs.

When safety matters most, advanced manufacturing solutions become essential—and friction drilling is proving to be the future of cylinder fabrication.