4-Axis CNC Drilling Machine Rapid-Drilling Aluminum Tubes — Why DUOMI CNC Leads the Industry

In modern metal fabrication, demand for fast, accurate, and stable drilling solutions on aluminum tubes has surged across industries such as fitness equipment, automotive frames, new-energy vehicle components, aerospace tubing, furniture structures, and performance engineering. As production volumes rise and precision requirements tighten, manufacturers are shifting away from manual and semi-automatic processes toward advanced multi-axis drilling equipment. Among all available solutions, the 4-Axis CNC Drilling Machine has emerged as the most efficient and reliable equipment for continuous drilling on round, square, and rectangular aluminum tubes.

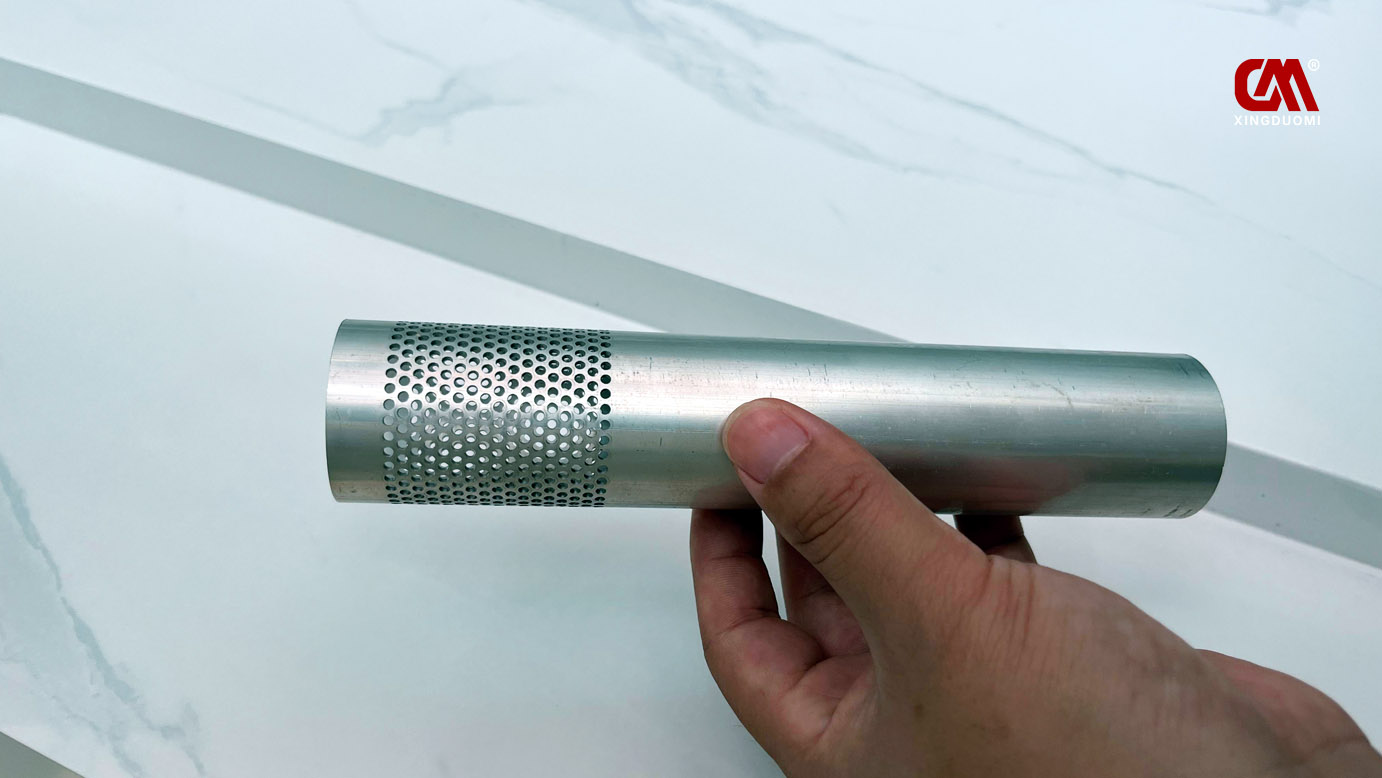

Hole Drilling Performance on Aluminum Round Tubes

DUOMI CNC, a global supplier of intelligent drilling and tapping technology, has become one of the most trusted brands for aluminum tube machining. With years of engineering experience and a deep understanding of CNC automation, DUOMI CNC delivers a specialized 4-Axis CNC Drilling Machine designed to achieve high-speed, high-accuracy drilling on aluminum tubes with unmatched consistency. This article explores why DUOMI CNC's system has become the go-to choice, and how its capabilities set a new benchmark in the field of Aluminum Tubes Drilling Machine technology.

1. Growing Demand for Precision Drilling on Aluminum Tubes

Aluminum tube structures are widely used due to their lightweight, corrosion resistance, good surface finish, and structural integrity. However, drilling on aluminum tubes presents challenges:

Tube walls are thin, requiring precise feed control

Round surfaces require accurate positioning to avoid slip

High-speed drilling generates heat that may affect hole quality

Consistency is difficult to maintain with manual operations

Multi-hole patterns must align perfectly for post-assembly fit

As a result, factories increasingly adopt automated multi-axis equipment—particularly the 4-Axis CNC Drilling Machine—which provides the directional stability and speed needed for high-volume drilling tasks.

The market demand for Aluminum Tubes Drilling Machines continues to expand, and manufacturers are actively seeking solutions that integrate speed, reliability, and cost-effectiveness. DUOMI CNC's 4-axis system directly addresses these industrial needs with its cutting-edge engineering.

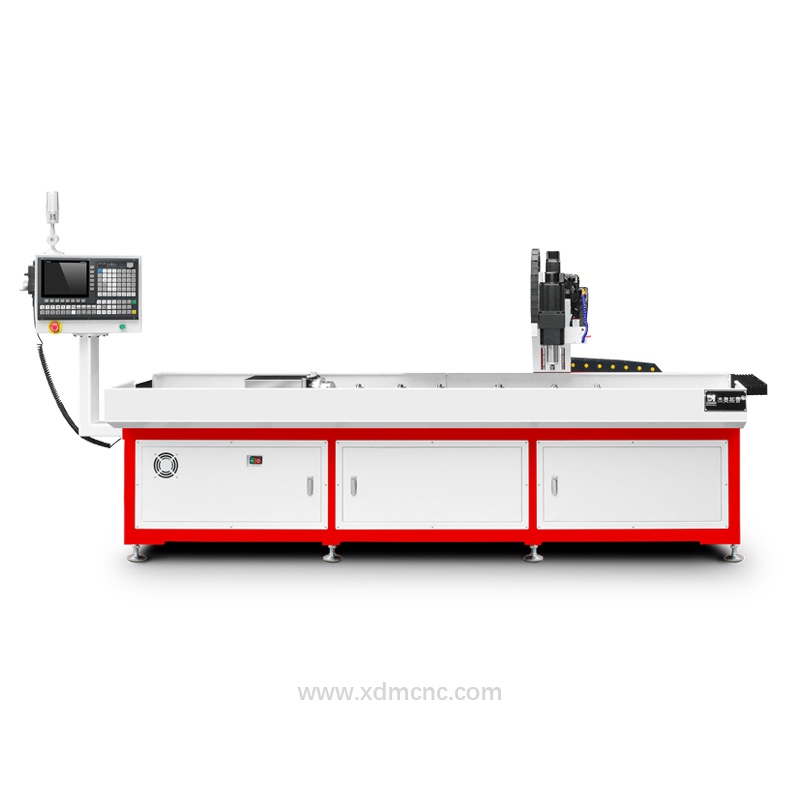

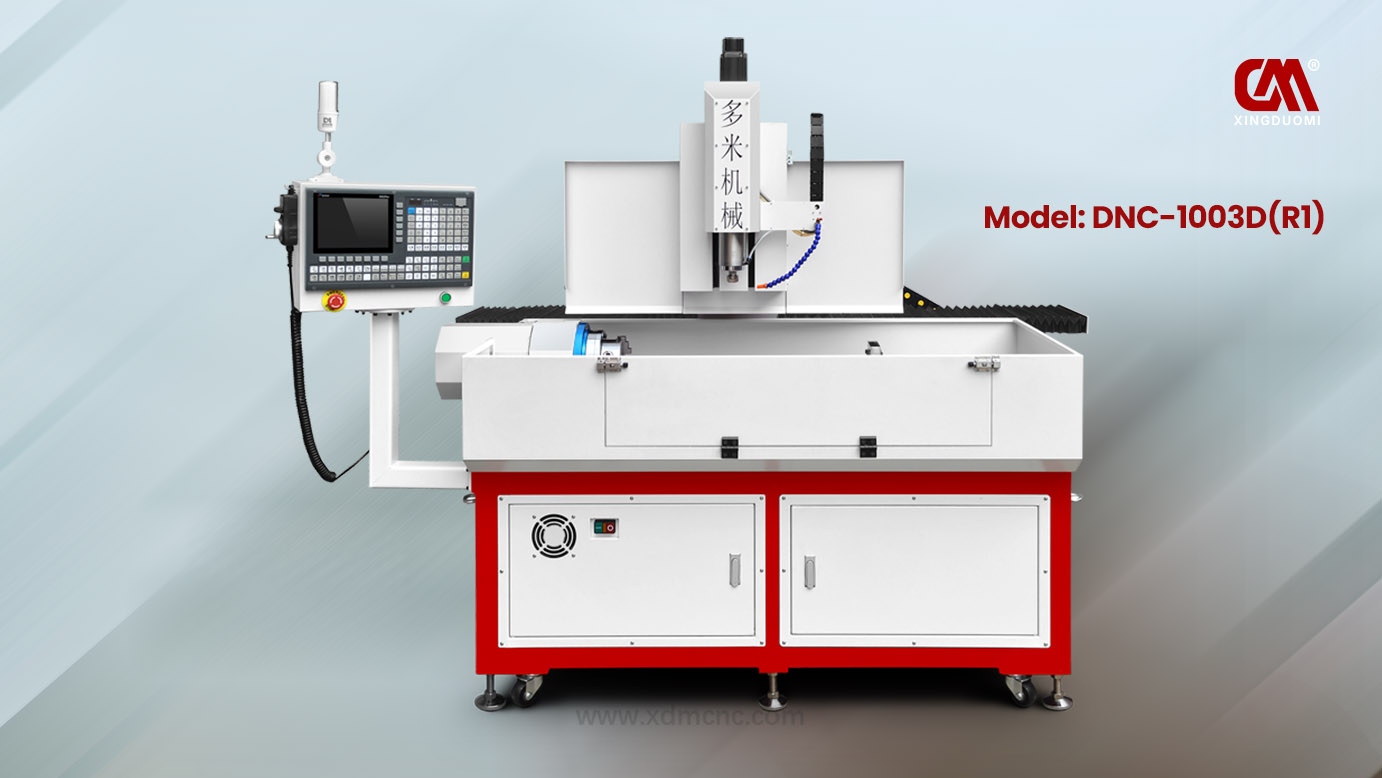

Recommended CNC Drilling Machine for Aluminum Round Tubes

2. What Makes a 4-Axis CNC Drilling Machine Essential for Aluminum Tubes?

A 4-axis CNC machine introduces rotational movement (usually the A-axis) that allows the tube to turn during drilling. This capability unlocks several key advantages:

2.1 True Multi-Side, Multi-Angle Drilling

Traditional 3-axis machines struggle when drilling on round tubes because the tool only approaches from fixed directions. The additional A-axis rotation enables:

Drilling around the circumference of aluminum tubes

Multiple hole patterns on different sides

Perfect hole alignment even with complex geometries

Reduced mechanical setups and faster production cycles

This makes the equipment ideal for mass production of structural aluminum tube components.

2.2 Continuous High-Speed Drilling for Batch Manufacturing

A high-performance Aluminum Tubes Drilling Machine must maintain stable spindle speed and feed control. DUOMI CNC's 4-axis system achieves:

Rapid tool positioning

Optimized cutting speed for aluminum

Clockwise/counterclockwise precise tube rotation

Consistent performance in long production runs

As a result, factories can achieve continuous drilling without the downtime associated with manual adjustment.

2.3 Improved Hole Quality and Precision

Thanks to dynamic coordination among X, Y, Z, and A axes, drilling accuracy is significantly enhanced:

Perfect hole positioning around curved surfaces

Low tolerance deviation

Uniform chip removal

Smooth hole edges suitable for tapping or assembly

For industries where safety and structural stability are crucial, such as automotive, bicycles, e-bike frames, and aerospace tubing, this level of precision is critical.

3. Why DUOMI CNC's 4-Axis CNC Drilling Machine Stands Out

There are many CNC drilling machines on the market, but DUOMI CNC's engineering makes its 4-axis system uniquely powerful for aluminum tube applications.

3.1 Dedicated Design for Aluminum Tube Drilling

DUOMI CNC fine-tuned its system specifically for aluminum materials, optimizing:

Spindle torque

Coolant delivery

Chip evacuation

High-speed spindle programming

Anti-slip tube clamping system

This ensures the machine handles thin-wall, medium-wall, and thick-wall aluminum tubes without deformation or tool wandering.

3.2 High-Rigidity Structure for Zero Vibration

Aluminum is soft but requires stable drilling to avoid bit chatter. DUOMI CNC machines feature:

A reinforced cast-iron base

Segmented heavy-duty linear guides

Servo-driven ball screw transmission

Vibration suppression engineering

Such rigidity ensures hole consistency during high-speed operations.

3.3 Smart Automation for Multi-Hole Tube Production

The DUOMI CNC 4-axis system supports:

Automatic tube loading/unloading (optional)

Customizable hole patterns

Auto compensation for tube diameter tolerances

Real-time position feedback

One-click program switching

This automation significantly reduces labor costs and operator error.

3.4 Superior Clamping for Round Aluminum Tubes

High-speed drilling requires strong but gentle tube clamping. DUOMI CNC uses:

Adjustable pneumatic or hydraulic clamping

Full-circle support fixtures

Anti-scratch rubberized surfaces

This keeps the tube perfectly centered while protecting its exterior finish.

3.5 Advanced CNC Control for Precision Performance

The DUOMI CNC interface enables:

Easy G-code programming

CAD/CAM import capability

Visual hole-position simulation

Digital angle control for A-axis rotation

Operators can set up new hole layouts in minutes—even for extremely complex tube designs.

3.6 A Global Reputation for Reliability

DUOMI CNC machines operate in more than 70 countries, and users praise:

Long machine lifespan

Low maintenance requirements

Reliable technical support

Stable performance even in 24/7 operations

This proven reliability makes it the preferred Aluminum Tubes Drilling Machine in the international market.

4. How DUOMI CNC Ensures Superior Drilling Results on Aluminum Tubes

4.1 Zero Burr and Zero Deformation Engineering

Through optimized toolpath programming and spindle settings, DUOMI CNC ensures:

Minimal edge burrs

No tube deformation

Perfect roundness around the hole

Clean entry and exit surfaces

For industries where surface quality matters—such as furniture, medical devices, and architectural aluminum structures—this is a decisive benefit.

4.2 High-Speed Production Without Overheating

Aluminum overheats easily during drilling, leading to tool wear and poor finish. DUOMI CNC counters this with:

Intelligent coolant flow

High-speed spindle optimized for aluminum alloys

Temperature-based feed-rate compensation

This ensures continuous drilling over long production cycles.

4.3 Perfect Hole Alignment Around the Tube

With 4-axis synchronized movement, DUOMI CNC achieves:

360-degree dynamic drilling

Accurate hole spacing even on curved surfaces

Alignment precision down to fractions of a millimeter

This eliminates assembly issues such as misalignment or structural weakness.

5. Key Applications of DUOMI CNC 4-Axis Aluminum Tube Drilling Machine

5.1 Fitness Equipment Manufacturing

Aluminum and steel tubes used in gym machines require precise hole alignment.

DUOMI CNC ensures:

Perfect symmetry

Multi-side drilling

Rapid production cycles

5.2 Bicycle and E-bike Frame Factories

Frame tubes require dense and accurately placed holes.

The 4-Axis CNC Drilling Machine allows:

High-consistency mass production

Zero misalignment during welding

Smooth drilled surfaces that enhance fatigue strength

5.3 Automotive and EV Structural Tubes

Lightweight aluminum components require perfect drilling precision.

DUOMI CNC supports:

Large-batch continuous drilling

Custom angles for structural joints

Automated hole positioning

5.4 Furniture and Display Rack Manufacturing

Aluminum frame furniture demands:

Smooth, clean holes

Aesthetic surface quality

High-speed drilling for large orders

5.5 Aerospace and Precision Tubing

Aerospace-grade aluminum requires accuracy above all else.

DUOMI CNC ensures:

Tight hole tolerance

Minimal thermal influence

Repeatability across thousands of units

6. The Competitive Advantage of DUOMI CNC Over Traditional Drilling Methods

6.1 One Machine Replaces Multiple Manual Stations

A single DUOMI CNC 4-axis machine replaces:

Manual drilling

Jig-based drilling

Rotary-position drilling

Angle drilling setups

This significantly reduces manpower and boosts productivity.

6.2 Faster Production at Lower Cost

Factories report:

3–6× faster production speed

60% reduction in labor cost

Higher yield rate

Lower consumable waste

6.3 Greater Flexibility

Unlike fixed drilling systems, DUOMI CNC machines adapt quickly to:

New product models

Different tube diameters

Various aluminum grades

Custom hole patterns

This flexibility supports rapid manufacturing response to market changes.

7. Why DUOMI CNC Is the Best Choice for Aluminum Tube Manufacturing

Customers choose DUOMI CNC because:

Its 4-Axis CNC Drilling Machine offers superior performance for aluminum tubes

The machine delivers unmatched speed, accuracy, and stability

The brand supports global customers with training and after-sales service

The equipment is engineered specifically for multi-hole, multi-side tube drilling

It is proven effective in large-scale manufacturing environments

DUOMI CNC is not just a machine provider—it is a long-term production partner offering reliable solutions for continuous drilling challenges in aluminum tube fabrication.

8. Conclusion: The Future of Aluminum Tube Drilling Belongs to 4-Axis CNC Technology

As industries continue to rely on lightweight and high-strength aluminum structures, the need for efficient drilling solutions will expand rapidly. The 4-Axis CNC Drilling Machine represents the most advanced and cost-effective technology for achieving fast, accurate, and stable drilling results on aluminum tubes.

With its optimized design, industrial-grade performance, and strong global reputation, DUOMI CNC delivers the ideal Aluminum Tubes Drilling Machine for manufacturers who demand high productivity and perfect drilling quality.

For factories aiming to improve efficiency, reduce labor cost, and maintain world-class precision, DUOMI CNC stands out as the undisputed best choice.