A professional delegation from Turkey recently visited DUOMI CNC, marking another milestone in the company's growing global presence in CNC drilling and tapping technology. The visit provided our Turkish guest with a close look at DUOMI's advanced production workshop, high-precision manufacturing process, and industry-leading thermal friction drilling machines.

Turkish Clients Conduct an In-Depth Inspection of Duomi CNC Drilling and Tapping Equipment

A Warm Welcome and Professional Technical Briefing

The Turkish visitor was welcomed by DUOMI's international sales team and senior engineers, who provided a full introduction to the company's R&D strengths and production capabilities. As Turkey remains one of the fastest-growing markets for metal processing equipment, the client expressed strong interest in DUOMI's CNC drilling machines, especially their application in steel tubes, stainless-steel pipe fittings, automotive components, fitness equipment tubes, and industrial frames.

Our technical director explained the advantages of DUOMI's equipment, including:

High-precision drilling and tapping stability

Long-life spindle structure designed for continuous operation

Industrial-grade servo control for maximum accuracy

Powerful thermal friction drilling technology

Automated multi-axis solutions for large-scale production

Turkish Clients Conduct an In-Depth Visit to DUOMI CNC Drilling & Tapping Equipment

Inside DUOMI CNC's Modern Production Workshop

During the workshop tour, the Turkish client saw how DUOMI machines are built from the ground up. The visit covered several key areas:

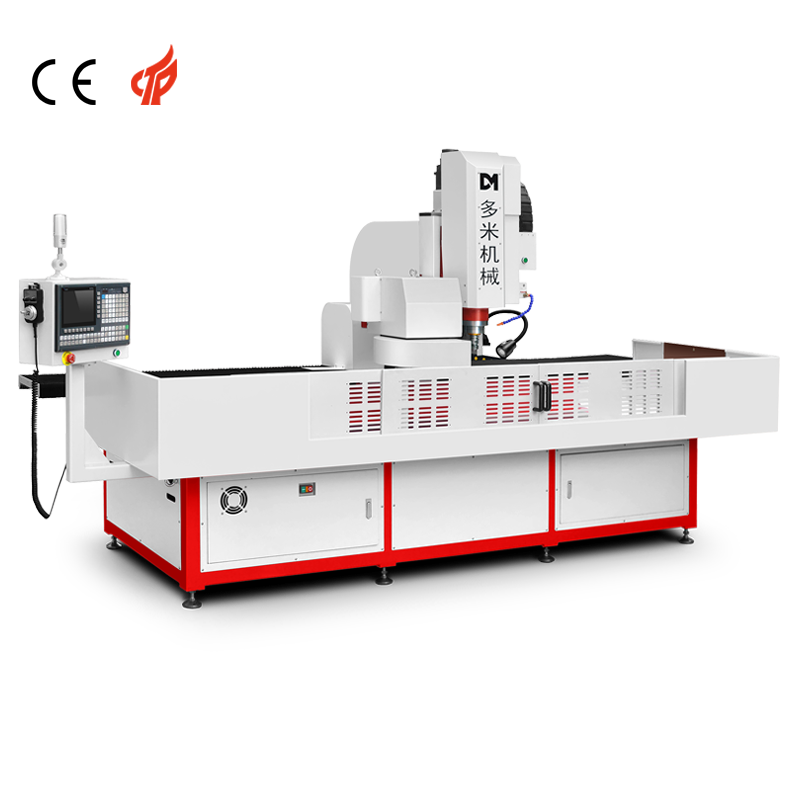

1. CNC Machine Assembly Line

Engineers demonstrated the assembly of multi-axis CNC drilling machines, ensuring each unit meets strict performance standards before shipping.

2. Thermal Friction Drilling Test Area

The client watched on-site demonstrations of thermal friction drilling on stainless steel and carbon steel tubes. They were impressed by the smooth finish, strong thread formation, and the ability to create deep, burr-free holes without welding nuts.

3. Quality Inspection Department

DUOMI's quality-control team showcased precision measuring equipment and explained how every critical component is inspected to guarantee long-term reliability.

Turkish Buyers Inspect DUOMI CNC Drilling–Tapping Machines Up Close

Hands-On Machine Testing and Real Production Scenarios

To help the Turkish client better understand machine performance, DUOMI arranged practical testing sessions with:

CNC drilling and tapping machine for square tubes

Multi-spindle CNC drilling machine

Thermal friction drilling and forming equipment

The visitor tested several drilling parameters, including feed rate, torque, spindle speed, and hole precision. Real-time results proved the machine's stability even under challenging conditions such as thick-wall steel and high-torque tapping.

Strong Interest in Future Cooperation

At the end of the visit, the Turkish client expressed high appreciation for DUOMI CNC's manufacturing capability, saying that the machining quality exceeded their expectations. They were particularly impressed by the clean workshop layout, the standardized workflow, and DUOMI's commitment to continuous technological innovation.

The customer noted that DUOMI CNC's equipment could greatly enhance production efficiency for Turkish manufacturers in sectors such as:

Fire safety equipment

Furniture tubes

Automotive pipes

Fitness equipment

Industrial machinery components

Energy and HVAC systems

Both parties agreed to continue technical discussions and explore the possibility of establishing long-term cooperation for the Turkish market.

Turkish Delegation Deeply Inspects DUOMI's CNC Drilling–Tapping Solutions

DUOMI CNC: Trusted Worldwide for CNC Drilling and Tapping Solutions

As a leading manufacturer specializing in CNC drilling, tapping, and thermal friction drilling machines, DUOMI CNC continues to expand its international footprint. The visit from the Turkish client reflects the increasing recognition of DUOMI's technology across global markets.

With strong R&D strength, high-precision assembly, and customer-oriented service, DUOMI CNC remains committed to helping manufacturers worldwide achieve higher productivity and better-quality machining results.