CNC Thermal Drilling and Tapping Machine DHM-2560N24

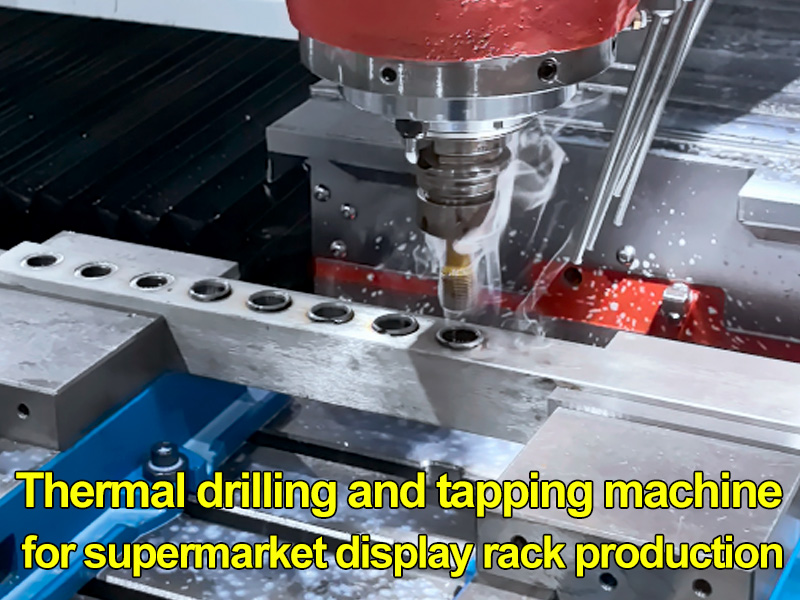

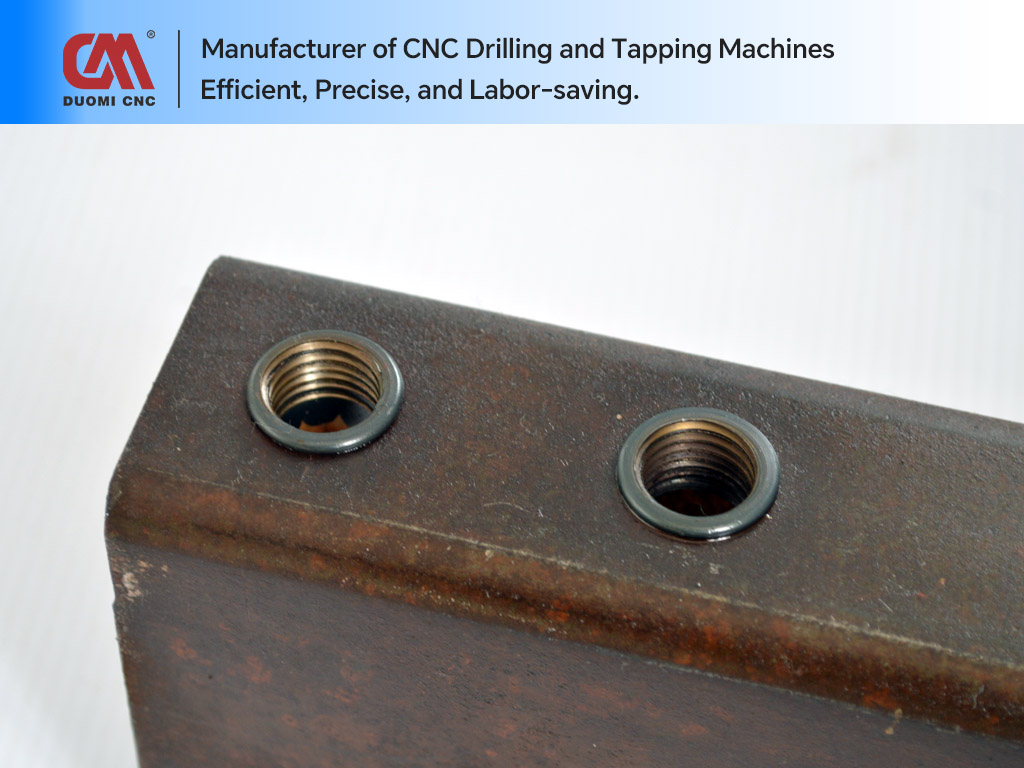

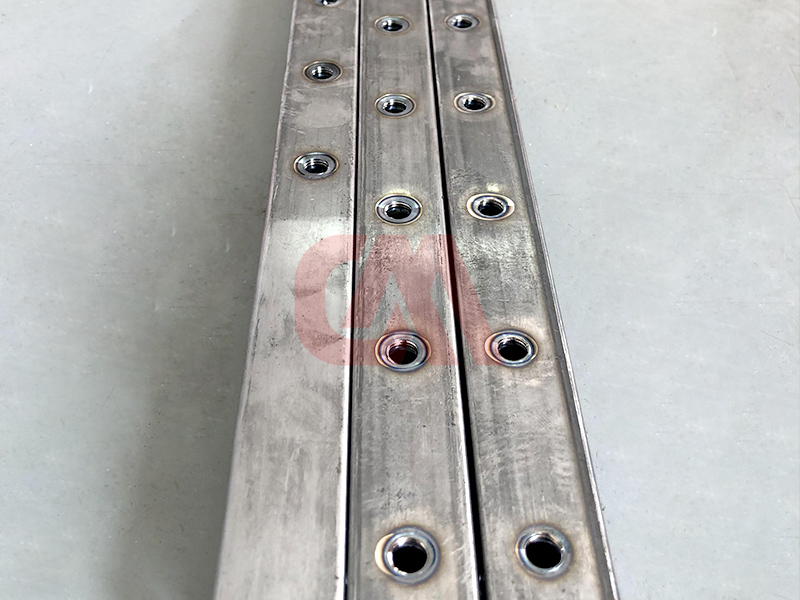

1. The DHM-2560N24 is a multifunctional machining center that integrates automatic thermal friction drilling, tapping, chamfering, and milling.

2. The overall structure of the machine is based on a one-piece cast-iron base for high rigidity and stability.

3. It adopts a mature and reliable CNC machining center control system, supporting multiple programming modes such as CAD drawing import with automatic program generation and teaching programming.

4. Equipped with a Taiwan-imported BT40 servo mechanical spindle, it is suitable for thermal friction drilling, tapping, chamfering, and milling of steel, iron, stainless steel, and other metal materials.

5. The machine comes with a 24-tool disc-type magazine that follows the spindle, using servo direct-drive tool change for fast and efficient tool switching.

6. The entire machine adopts absolute-value servo motor drive control, ensuring excellent positioning accuracy, high stability, and fast response speed.

7. X, Y, and Z axes are equipped with limit protection functions to prevent operator errors from damaging the machine.

8. Each axis is equipped with an automatic lubrication system with adjustable timing and dosage, ensuring consistent lubrication at critical points, eliminating the need for manual oiling and reducing maintenance requirements.

9. The whole machine undergoes precision compensation using a U.S.-imported API laser interferometer, resulting in higher machining accuracy, precise tool positioning, and reduced tool wear.

Request A Quote

Request A Quote