When you’re running a factory or a busy production line, every second counts. Delays, tool wear, and inconsistent holes can throw off your entire schedule. That’s exactly why so many manufacturers are urgently searching for a Form Drilling Machine that actually delivers precision, speed, and reliability. If you’re here reading this, chances are you’ve been frustrated with traditional drilling setups that waste time and money. Let’s dive into why a Form Drilling Machine from DUOMI CNC is the breakthrough you’ve been waiting for.

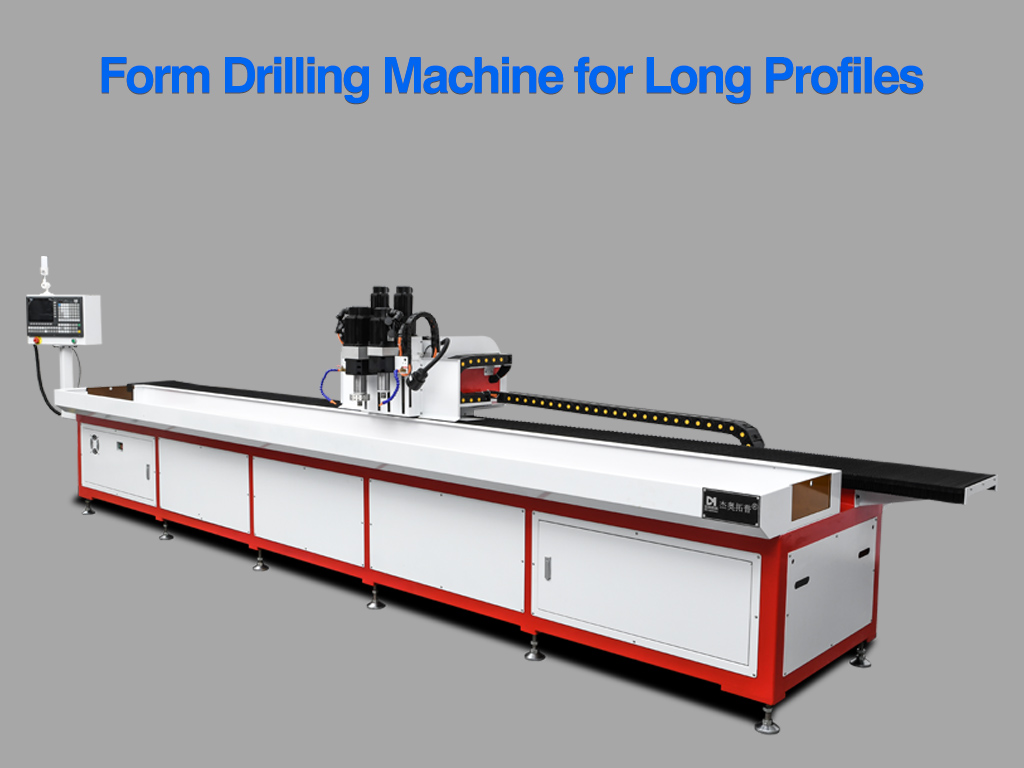

Form Drilling Machine for Long Profiles

Why Traditional Drilling Methods Are Holding You Back

Before we talk about solutions, let’s address the pain points. If you’ve used conventional drilling systems, you know the problems all too well:

Excessive tool wear – Bits dull quickly, meaning higher replacement costs.

Low consistency – Each hole comes out slightly different, impacting precision parts.

Heat issues – Conventional drills can’t handle high-speed friction, leading to deformations.

Slow productivity – When you need thousands of holes, traditional methods simply can’t keep up.

These headaches don’t just cause stress—they directly hit your bottom line. You lose valuable hours, compromise quality, and end up disappointing clients. That’s why so many manufacturers are searching right now for a better solution: the Form Drilling Machine.

What Makes a Form Drilling Machine Different?

A Form Drilling Machine is not just another drill—it’s a completely different technology. Instead of cutting material away, it uses frictional heat to form a bushing out of the existing metal. The result? Stronger joints, clean holes, and reduced waste.

Key benefits include:

Extended tool life – Tools last up to 10x longer compared to conventional drills.

No chips, no mess – You don’t waste material; instead, you reshape it.

Stronger threads – The formed bushing provides more material for tapping threads.

High speed – Perfect for mass production in automotive, aerospace, and industrial fields.

DUOMI CNC’s Form Drilling Machine takes these advantages even further with precision CNC integration, automated controls, and customizable options tailored to your production needs.

Why Customers Are Urgently Choosing Form Drilling Machines

If you’re reading this article, chances are you’re under pressure to solve production issues quickly. You’re not alone. Many of our customers came to us in the same situation—needing a machine that can keep up with tight deadlines and demanding quality standards.

Here’s what one of our automotive industry clients shared:

“We were struggling to produce consistent threaded holes in stainless steel parts. Tool wear was costing us thousands every month. After switching to the DUOMI CNC Form Drilling Machine, our production speed doubled, tool costs dropped dramatically, and the threads we produce now are stronger than ever. It changed the game for us.” – Production Manager, Automotive Supplier in Germany

This isn’t just about upgrading a machine—it’s about upgrading your entire workflow.

Form Drilling Machine Applications Across Industries

The versatility of a Form Drilling Machine makes it a must-have for multiple industries:

Automotive – High-volume threaded holes for frames, exhaust systems, and components.

Aerospace – Stronger connections in lightweight alloys, critical for safety and durability.

Construction Equipment – Durable joints for heavy-duty machinery.

Electronics & Appliances – Small precision holes without material waste.

No matter your field, if you’re dealing with sheet metal, stainless steel, aluminum, or copper alloys, a Form Drilling Machine will outperform your current setup.

Why Choose DUOMI CNC?

There are plenty of machine suppliers out there, but DUOMI CNC stands out for three big reasons:

Customization – We don’t sell “one-size-fits-all.” Each machine can be built to match your exact material, size, and production needs.

Global reach – With shipments from major Chinese ports (Shanghai, Shenzhen, Qingdao, Guangzhou), we can deliver quickly to any customer worldwide—or ship from a port you specify.

Peace of mind – Every machine comes with a fast lead time and a worry-free warranty. You focus on production, we handle the rest.

How to Know If You Need a Form Drilling Machine Right Now

Still wondering if a Form Drilling Machine is the right investment? Ask yourself these questions:

Are you replacing drill bits too often?

Do you have quality issues with inconsistent holes?

Is production speed limiting your business growth?

Are you under pressure from clients to deliver faster?

If you answered “yes” to any of these, the answer is clear: it’s time to invest in a Form Drilling Machine from DUOMI CNC.

Final Thoughts – Don’t Wait to Upgrade

In today’s fast-paced manufacturing world, waiting to modernize your production means falling behind competitors. A Form Drilling Machine isn’t just a purchase—it’s a long-term solution to the biggest pain points of traditional drilling.

When you choose DUOMI CNC, you’re not only getting a machine—you’re getting a partner dedicated to your success. Our clients worldwide in aerospace, automotive, and industrial sectors trust us because we deliver precision, speed, and reliability every time.

So if you’ve been searching desperately for the right solution, your search ends here. The Form Drilling Machine from DUOMI CNC is the tool that will keep your factory competitive, efficient, and profitable.

Ready to take the next step? Contact DUOMI CNC today and let’s customize your Form Drilling Machine to meet your exact production needs.