Pipe Drilling Machine – Precision for Every Tube

When it comes to processing round, square, or rectangular pipes, precision and speed are critical. A pipe drilling machine offers a professional solution for creating clean, accurate, and repeatable holes on metal tubes used in structural frameworks, furniture, fitness equipment, and industrial systems.

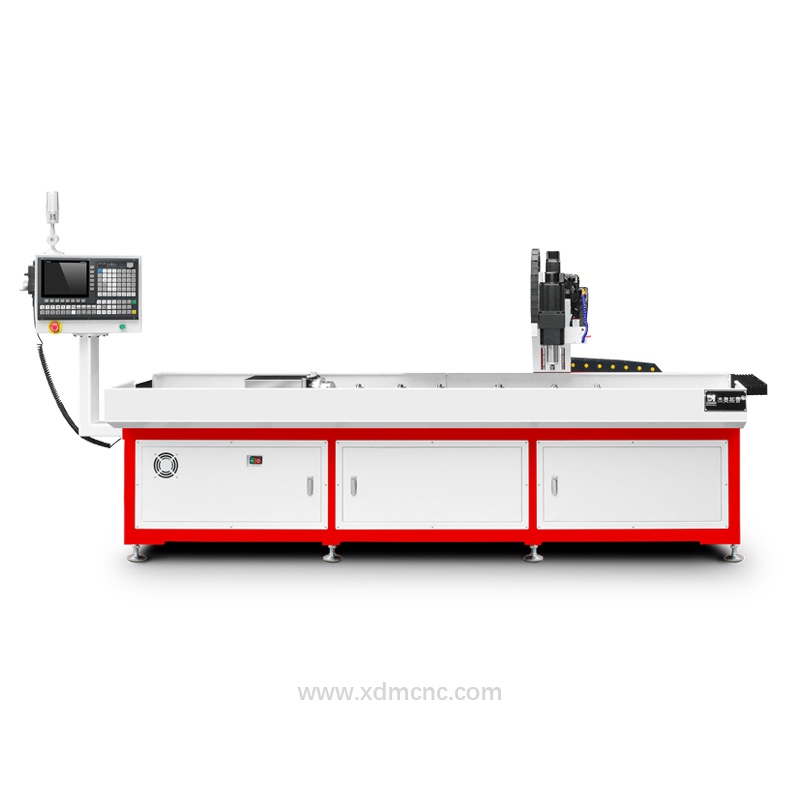

High-Speed Pipe Drilling Machine

DUOMI CNC is a leading manufacturer of advanced CNC pipe drilling machines, designed to automate and optimize the hole-drilling process on metal pipes of all shapes and sizes. Our machines ensure accurate positioning, fast cycle times, and outstanding hole quality, making them ideal for high-volume production and custom fabrication.

What Is a Pipe Drilling Machine?

A pipe drilling machine is a specialized CNC or semi-automatic system designed to drill holes on the surfaces of metal pipes. Unlike standard drilling machines, it is equipped with pipe-holding fixtures, rotary axis systems, and software that can compensate for pipe curvature and wall thickness.

Whether you're working with:

Round pipes

Square tubes

Rectangular hollow sections (RHS)

DUOMI CNC's machines can handle it all—offering high-precision drilling for diameters ranging from 0.5mm to 20mm.

Benefits of Using DUOMI CNC Pipe Drilling Machine

Upgrading to a DUOMI pipe drilling machine can dramatically improve your production quality and efficiency. Here's how:

1. Accurate Hole Positioning

With ±0.01mm repeatability, our machines ensure holes are drilled exactly where you want them—critical for load-bearing or assembly-fit applications.

2. Fast Cycle Time

Thanks to servo motors and intelligent feed control, DUOMI CNC pipe drilling machines reduce processing time by up to 40% compared to manual setups.

3. Multi-Face Drilling

Drill on multiple sides of square or rectangular tubes in one pass with rotating or multi-spindle head configurations.

4. Compatibility with Various Pipe Materials

Whether you're drilling mild steel, stainless steel, aluminum, brass, or galvanized pipes, our machines are built for performance and durability.

5. Reduced Labor and Rework

One operator can oversee multiple machines simultaneously, reducing your labor costs while increasing accuracy and consistency.

Applications of Pipe Drilling Machines Across Industries

A pipe drilling machine is essential in a wide range of industries where tube-based frameworks or components are manufactured:

Furniture Industry: Chairs, tables, and bedframes made from square or round tubes

Fitness Equipment: Gym racks, weight machines, and exercise benches

Construction: Steel scaffolding, pipe structures, and handrails

Automotive: Exhaust pipe components and protective frames

Greenhouses & Display Racks: Tubular frames requiring quick assembly

With a DUOMI CNC machine, each application benefits from faster production, cleaner holes, and perfect alignment.

Real-World Case Study

A DUOMI CNC customer in Southeast Asia, manufacturing stainless steel gym equipment, replaced manual drilling with our CNC pipe drilling machine. In just three months, the results included:

50% increase in production output

75% reduction in rework and misalignment issues

Faster delivery time and higher customer satisfaction

DUOMI CNC Pipe Drilling Machine Specifications

Feature Specification

Pipe Type Support: Round, Square, Rectangular Tubes

Max Drilling Diameter: 0.1mm – 20mm

Pipe Length Capacity: Up to 6 meters (customizable)

Axis Configuration: 3-axis / 4-axis / Rotary axis

Positioning Accuracy: ±0.01mm

Control System: DUOMI's independently developed system

Material Compatibility: Steel, Aluminum, Brass, Stainless

Automation Integration: Available (robotic arm, conveyors)

Why Choose DUOMI CNC for Your Pipe Drilling Needs?

At DUOMI CNC, we‘re not just selling machines—we provide smart manufacturing solutions. Here's why clients in over 40 countries choose DUOMI:

Over 15 years of CNC manufacturing expertise

OEM & ODM services tailored to your production needs

Global technical support and fast parts supply

Custom fixture design for different pipe shapes and hole patterns

Excellent price-performance ratio with strong ROI

Every DUOMI CNC pipe drilling machine is tested under real production conditions before shipping, ensuring you receive reliable equipment ready for action.

Easy Integration with Your Existing Workflow

Our pipe drilling machines are compatible with existing welding, tapping, and cutting stations. You can:

Add automatic feeding for long pipes

Connect to tapping or chamfering modules

Integrate barcode scanners and product traceability systems

Whether you run a high-volume factory or a flexible job shop, DUOMI machines adapt to your pace and complexity.

Contact DUOMI CNC for a Free Quote or Live Demo

Ready to upgrade your production line with a fast, accurate, and reliable pipe drilling machine? DUOMI CNC offers:

Free material testing

Custom solution design

Machine demos via video or onsite (depending on region)

Fast delivery and responsive after-sales support

Contact us today to find the perfect pipe drilling machine solution for your industry and start saving time, money, and labor—while improving quality and consistency.