Metal Drilling Machine – Power Meets Precision

In modern manufacturing, precision drilling is a cornerstone of high-quality metal fabrication. Whether you're producing automotive parts, structural components, or industrial equipment, a metal drilling machine is essential for accurate, clean, and efficient hole making.

At DUOMI CNC, we specialize in advanced metal drilling machines designed for high-speed operations, excellent surface finish, and exceptional durability. With performance improvements of up to 45% compared to conventional machines, our equipment is built to boost productivity while maintaining strict tolerances.

What Is a Metal Drilling Machine?

A metal drilling machine is an industrial-grade device used to create holes in various metal materials such as steel, aluminum, copper, brass, or titanium. These machines use a rotating drill bit to cut through the metal with accuracy and speed, making them critical in industries like:

Automotive manufacturing

Aerospace

Construction and infrastructure

Furniture and fitness equipment

Electronics and electrical enclosures

Depending on the complexity and volume of your tasks, metal drilling machines come in different types—manual, semi-automatic, and CNC-controlled systems.

Benefits of Using a CNC Metal Drilling Machine

Investing in a high-performance metal drilling machine offers several key advantages for manufacturers seeking quality and efficiency.

1. High Accuracy and Repeatability

Our CNC metal drilling machines achieve positioning accuracy of ±0.005mm, ensuring consistent drilling even on thin or irregular surfaces.

2. Greater Productivity

With rapid tool changes, multi-spindle support, and automatic feeding, DUOMI CNC machines can reduce your cycle times by 30–50%, depending on the material and hole diameter.

3. Flexibility for Multiple Materials

Whether drilling into stainless steel, cast iron, or lightweight aluminum alloys, our metal drilling machines automatically adjust parameters to prevent tool wear and overheating.

4. Reduced Human Error

CNC automation reduces dependency on manual labor, eliminating common mistakes and rework. Operators only need minimal training to run complex programs.

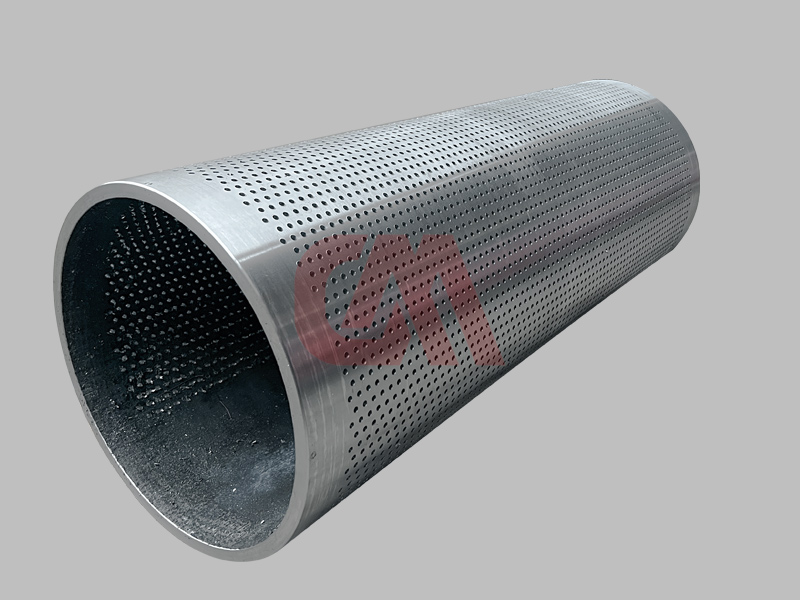

CNC drilling machine for metal drill

Applications of Metal Drilling Machines Across Industries

A powerful metal drilling machine is not limited to just heavy industry. It finds applications in various precision sectors including:

Automotive Parts Production: Axle brackets, suspension arms, and transmission housings

Fitness Equipment Fabrication: Round and square tubing for weight benches and racks

Aerospace Engineering: Titanium parts requiring micro-hole drilling

Electrical Panels: Clean and burr-free holes for cable glands and terminals

Metal Furniture & Displays: Drilling in thin wall tubes or sheet metals

The versatility of DUOMI's machines makes them ideal for both high-volume production lines and job shops with custom orders.

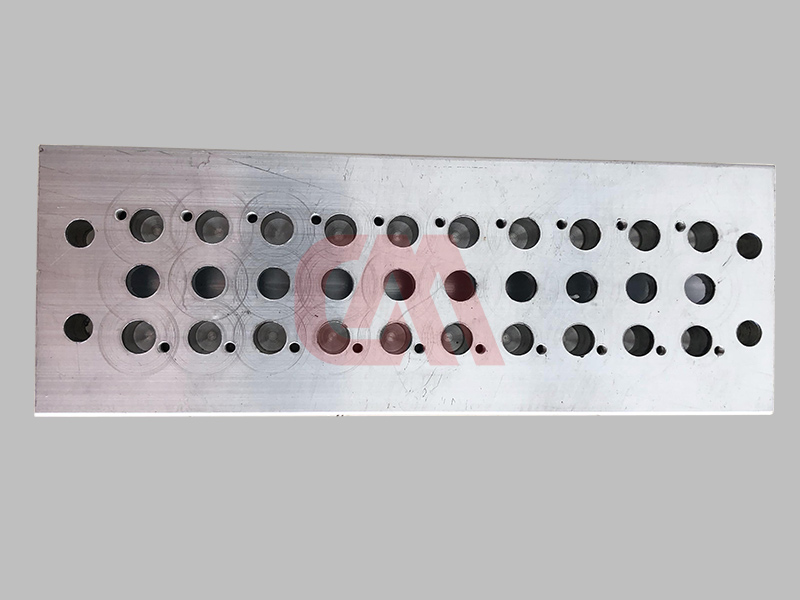

CNC drilling machine for Stainless Steel Plate

Material Compatibility

Our metal drilling machines can handle:

Carbon steel

Stainless steel

Aluminum and its alloys

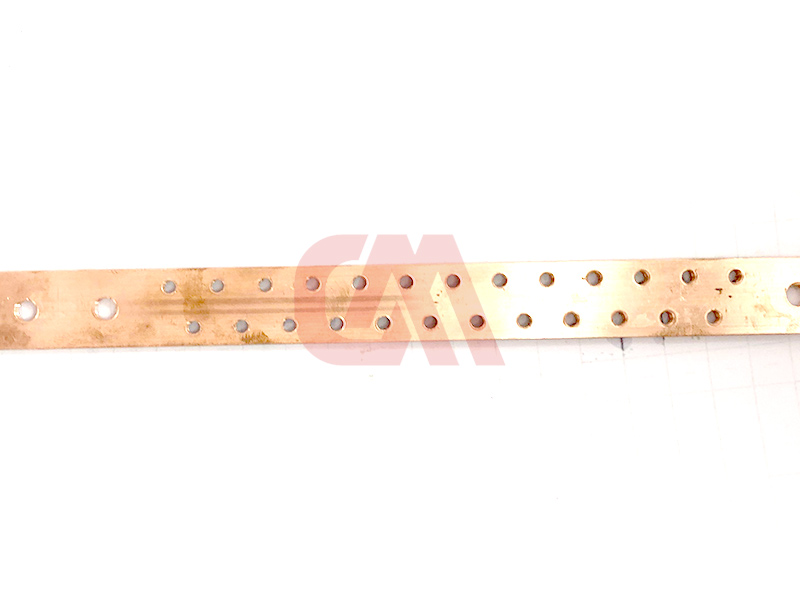

Brass and copper

Galvanized metals

Titanium and Inconel (specialized tooling available)

Key Features of DUOMI Metal Drilling Machine

DUOMI CNC's metal drilling machine lineup includes compact bench-top models to large-format gantry systems. Common features include:

Servo-driven X/Y/Z Axis for accurate movement

Multi-Spindle Options for simultaneous drilling

Digital Control System (SIEMENS/FANUC) with touchscreen interface

Automatic Cooling & Chip Removal to extend tool life

Optional Tapping, Countersinking, and Reaming Modules

We also offer custom configurations based on your part drawings or processing needs.

CNC Drilling and Tapping for Copper Sheet Metal

Real-World Case Study

A client in the automotive aftermarket industry recently switched to DUOMI's high-speed metal drilling machine to process 3mm-thick carbon steel brackets. Results included:

40% reduction in machining time

20% increase in overall output

60% lower defect rate from improved hole accuracy

This translated into significant cost savings and faster turnaround times for their customers.

Choose the Right Metal Drilling Machine for Your Workshop

Before choosing a metal drilling machine, consider the following:

Hole Size Range: What diameters and depths do you need?

Material Type: Harder metals may require specific tooling or coolant systems

Production Volume: High-run environments need automation to reduce downtime

Available Space: Choose between compact machines or full gantry solutions

DUOMI CNC's engineers will help you identify the right machine model based on your technical requirements and budget.

Why DUOMI CNC?

As a trusted name in metalworking machinery, DUOMI CNC offers:

Over 15 years of experience in industrial CNC drilling

Machines sold in 30+ countries worldwide

Full support for installation, training, and after-sales service

OEM customization based on part drawings and production needs

CNC Flange Drilling Machine for Drilling Small Holes in Stainless Steel Flanges

Request a Quote or Live Demo of Our Metal Drilling Machine

Ready to upgrade your production line with a high-efficiency metal drilling machine? DUOMI CNC provides:

Free part testing on your materials

Video demonstrations of machine operation

Quick delivery and technical support in your region

Contact us today to receive a detailed quote and get started on automating your drilling process with unmatched accuracy and speed.