Unlock Precision and Productivity with the 4-Axis CNC Drilling Machine

In today's competitive manufacturing landscape, precision, speed, and versatility are essential. That's where the 4-Axis CNC Drilling Machine comes in — a powerful solution engineered to meet the complex demands of modern production lines. Whether you're working in metal fabrication, automotive components, furniture hardware, or industrial assembly, the 4-axis CNC drilling system delivers unmatched efficiency and accuracy.

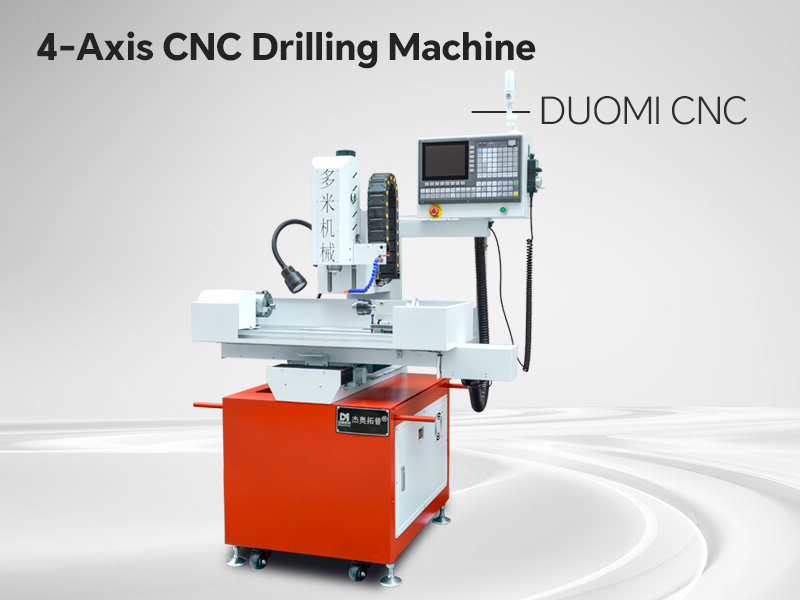

Click on the image for more details

What is a 4-Axis CNC Drilling Machine?

A 4-Axis CNC Drilling Machine is an advanced piece of equipment designed to drill, bore, and machine workpieces on multiple surfaces without the need to reposition the part manually. Unlike traditional 3-axis systems that move in X, Y, and Z directions, the 4-axis machine adds rotational capability around one axis (usually the A-axis), allowing it to access side surfaces of a part or drill at specific angles. This capability drastically reduces setup time, minimizes human error, and increases production throughput.

Why Choose a 4-Axis CNC Drilling Machine?

1. Enhanced Productivity

By enabling simultaneous multi-surface machining, a 4-axis CNC drilling machine reduces the need for repositioning workpieces. This automation translates to faster cycle times and increased daily output.

2. Unmatched Accuracy

Computerized controls and precise servo motors ensure every hole is drilled with exact positioning and depth, critical for industries where tolerances are tight.

3. Multi-Material Compatibility

Whether you're working with steel, aluminum, brass, stainless steel, or even composite materials, the 4-axis CNC drilling machine handles it with consistency and precision.

4. Complex Part Geometry

For manufacturers producing components with angled holes, curved surfaces, or cylindrical features, 4-axis functionality is indispensable. It simplifies the process of working on non-flat parts.

5. Labor Cost Reduction

Automating your drilling processes reduces reliance on skilled manual labor and minimizes the potential for operator fatigue or inconsistency.

Key Applications of 4-Axis CNC Drilling Machines

The versatility of a 4-axis CNC drilling machine makes it ideal for a wide range of industrial applications:

Metal Furniture Frame Fabrication – Drill accurate holes in square or round tubes for connectors, bolts, or welding preparation.

Automotive and EV Components – Ensure high-precision hole alignment on brackets, support frames, and subassemblies.

Fitness Equipment Manufacturing – Create repeatable holes in tubular structures for handlebars, joints, or resistance mechanisms.

Electronics Enclosures – Precision drilling for mounting points or heat dissipation layouts on aluminum housings.

Industrial Machinery Parts – Achieve complex hole patterns and angled drilling on mechanical assemblies.

Continuous high-precision drilling on stainless steel filter tubes with a 4-axis CNC drilling machine.

Features to Look for in a Quality 4-Axis CNC Drilling Machine

If you're considering investing in this powerful tool, make sure your 4-axis CNC drilling machine includes:

Robust Frame Design – A rigid structure for vibration-free drilling

High-Speed Spindle – Capable of both rapid and heavy-duty operations

User-Friendly CNC Controller – Intuitive interface for simplified programming and control

Automatic Tool Changer (ATC) – Optional but valuable for enhancing workflow

Cooling and Chip Removal System – Keeps your workspace clean and extends machine life

Boosting Efficiency in Your Workshop

Integrating a 4-Axis CNC Drilling Machine into your workshop is not just a technical upgrade — it’s a strategic move. You'll be able to:

Shorten delivery times

Increase consistency across large production batches

Handle more complex part designs

Enhance your reputation as a high-precision manufacturer

Optimize for Growth

As global demand increases for customized, lightweight, and precision-engineered products, investing in a 4-axis CNC drilling system positions your business for long-term competitiveness. Whether you're a small-scale workshop or a full-scale production facility, upgrading to a CNC system with four axes allows you to take on more challenging projects with confidence.

Conclusion

The 4-Axis CNC Drilling Machine is more than just a tool — it's a game-changer for any manufacturer seeking precision, speed, and flexibility. From boosting output and improving part quality to reducing manual labor and enabling complex designs, this machine brings transformative benefits to your production line. If you’re looking to enhance your manufacturing capability, now is the time to invest in advanced CNC drilling technology.

Contact us today to learn more about our 4-axis CNC drilling solutions and how they can revolutionize your operations.