Take Precision Manufacturing to the Next Level with a 5-Axis CNC Drilling Machine

In today's era of advanced manufacturing, businesses are under constant pressure to deliver higher precision, faster turnaround, and greater design complexity. Whether you're producing aerospace components, medical devices, or precision tooling, the 5-Axis CNC Drilling Machine stands out as the ultimate solution for high-performance drilling and machining.

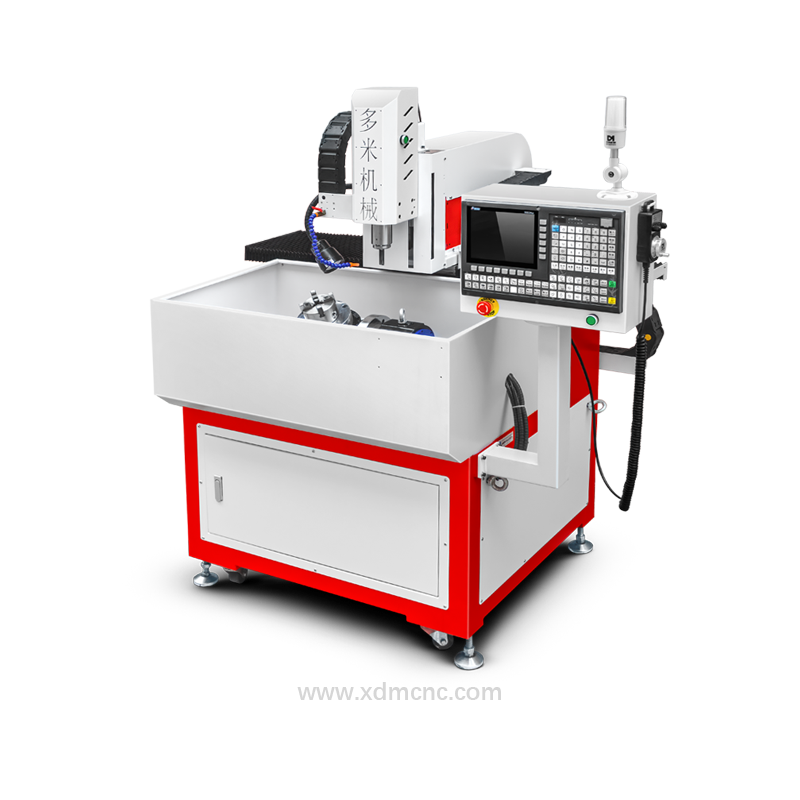

Click on the image for more details

What is a 5-Axis CNC Drilling Machine?

A 5-Axis CNC Drilling Machine is a high-precision, computer-controlled machine that operates along five different axes simultaneously — X, Y, Z (linear movement), and two rotational axes (usually A and B or A and C). This advanced capability enables complex machining tasks such as angled drilling, undercutting, and multi-surface drilling in a single setup.

Unlike traditional 3-axis or 4-axis machines, the 5-axis system eliminates the need for repositioning the workpiece, drastically improving accuracy and productivity while reducing setup time and human error.

Why Choose a 5-Axis CNC Drilling Machine?

1. Unparalleled Precision and Flexibility

With five axes working together, the machine can approach the part from virtually any angle, allowing for intricate hole placement on complex geometries, including spherical, cylindrical, and compound-curved surfaces.

2. Reduced Setup Time

The ability to machine multiple faces in one go eliminates the need for multiple fixtures or repositioning, which saves significant setup time and minimizes tolerance errors.

3. Superior Surface Finish

Because the tool maintains a more consistent angle to the workpiece, the resulting surface finish is smoother and more consistent — ideal for high-end components.

4. Complex Geometry Handling

Whether you're working with turbine blades, mold cavities, orthopedic implants, or multi-angle connectors, a 5-axis CNC drilling machine can handle intricate part designs that are impossible with traditional methods.

The impeller of petroleum equipment components is machined using a 5-axis CNC drilling and tapping process.

5. Increased Tool Life

Thanks to optimal cutting angles and tool positioning, tool wear is minimized — lowering operational costs and increasing tool longevity.

Industrial Applications of 5-Axis CNC Drilling Machines

The capabilities of a 5-axis CNC drilling machine make it an essential tool across a wide range of high-tech industries:

Aerospace Manufacturing – Drill and machine complex, lightweight aluminum or titanium structures with tight tolerances.

Automotive Engineering – Create multi-angle holes in engine blocks, transmission cases, or suspension parts with ease.

Medical Equipment Production – Precision drill orthopedic implants, surgical tools, or bone plates with micrometer accuracy.

Energy and Power Sector – Machine drilling patterns in turbine components, heat exchangers, and pressure vessels.

Die and Mold Industry – Produce complex cooling channels and core details with accurate angled drilling paths.

Key Features of a High-Quality 5-Axis CNC Drilling Machine

When selecting a 5-Axis CNC Drilling Machine, look for features that enhance performance and ease of use:

High-Speed Spindles – For efficient material removal across metals, composites, and plastics.

Advanced CNC Control System – Intuitive interface for real-time adjustments and complex tool path programming.

Robust Machine Bed – Ensures vibration-free operation and long-term structural accuracy.

Automatic Tool Changer (ATC) – Seamless multi-tool operations for uninterrupted workflow.

Cooling & Chip Management System – Essential for maintaining machining precision and system health.

Why "5-Axis CNC Drilling Machine" Matters

Boost Your Production with Next-Gen Drilling Technology

Investing in a 5-axis CNC drilling machine means:

Higher output per shift

Better component quality

Faster turnaround for complex orders

Increased customer satisfaction

Reduced waste and rework

As industries shift toward high-mix, low-volume production with more intricate part requirements, the 5-axis CNC drilling machine is not just a tool — it's a competitive edge.

Conclusion: Embrace the Future of Drilling with 5-Axis CNC

The 5-Axis CNC Drilling Machine is revolutionizing modern manufacturing. Whether you're looking to expand your machining capabilities, improve quality control, or accelerate production speed, this machine delivers unmatched performance. It's the perfect investment for forward-thinking manufacturers aiming to lead in precision and innovation.

Ready to upgrade? Contact us today to learn more about how our 5-axis CNC drilling solutions can transform your operations.