Small CNC Drilling Machine for Precision Metal Components: Redefining Accuracy and Efficiency

Introduction: The Demand for Precision in Modern Metalworking

In today's fast-paced manufacturing world, precision and efficiency are no longer optional—they are essential. Industries such as electronics, medical devices, and precision engineering rely on extremely accurate holes and threads in metal components to ensure reliable performance. However, achieving this level of precision has long been a challenge with traditional manual drilling setups.

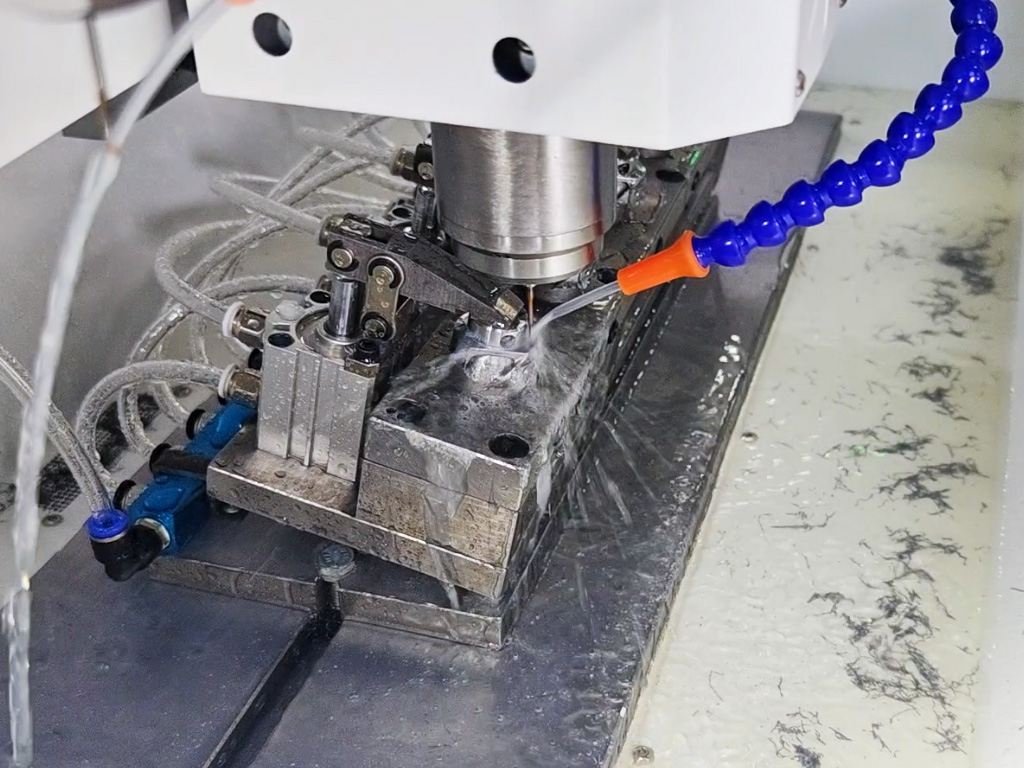

Small CNC Drilling Machine for Precision Metal Components

This is where the small CNC drilling machine steps in as a game-changer. Compact yet powerful, this advanced equipment is designed to handle intricate drilling operations on small and medium-sized metal components with unmatched accuracy. At DUOMI CNC, we've engineered our small CNC drilling machines to deliver industrial-grade results within a smaller footprint, making them the perfect solution for high-value, precision-focused manufacturing.

What Makes a Small CNC Drilling Machine Different

Unlike conventional drill presses, a small CNC drilling machine offers computer-controlled motion along multiple axes, allowing precise hole placement with micron-level accuracy.

Compact Size, Industrial Strength

Despite its smaller dimensions, DUOMI CNC's machines integrate rigid cast-iron frames and servo-driven spindles to minimize vibration and ensure stable, consistent drilling. This combination of strength and precision enables continuous operation even in demanding production lines.

Intelligent Control and Automation

Equipped with a user-friendly CNC interface, operators can program complex hole patterns directly into the system. Automated feed rate control, real-time spindle feedback, and repeat positioning accuracy eliminate human error and reduce production waste.

Versatility Across Materials

From aluminum and stainless steel to brass and copper alloys, DUOMI CNC's small drilling machines adapt easily through variable speed control and tool change options, allowing seamless transitions between materials without compromising quality.

Solving Traditional Drilling Pain Points

Manual or semi-automatic drilling setups often struggle with problems like:

Inconsistent hole alignment

Tool breakage due to uneven feed pressure

Time-consuming setup for multi-hole patterns

Human fatigue leading to lower accuracy

The small CNC drilling machine eliminates these issues by automating positioning, feed rate, and drilling depth. This ensures each hole—whether it's 0.2 mm or 10 mm in diameter—is produced with perfect consistency.

For example, in the production of electronic connector housings, hundreds of micro-holes must be drilled precisely to maintain electrical isolation. Manual methods are nearly impossible at such tolerances, but DUOMI CNC machines handle it effortlessly through programmable coordinates and stable spindle speeds.

Applications in Precision Metal Components

Electronics and Communication Equipment

In electronic parts like heat sinks, connectors, and circuit housings, a small CNC drilling machine provides superior surface finish and tight tolerance control. Its ability to repeat high-precision operations ensures that even miniature holes align perfectly for component assembly.

Medical and Dental Instruments

The medical device industry demands extreme accuracy and burr-free drilling for stainless steel and titanium parts. DUOMI CNC machines maintain high rotational precision and temperature stability, ensuring clean holes ideal for implants, surgical instruments, and diagnostic devices.

Precision Engineering Components

Small shafts, brackets, and mechanical connectors all require accurate drilling for fit and assembly. The DUOMI CNC small drilling machine's automatic positioning and repeatable accuracy greatly improve throughput and reduce rework rates.

Key Features of DUOMI CNC Small Drilling Machines

Servo Motor and Ball Screw Drive – Ensures smooth linear movement and micron-level precision.

Automatic Lubrication and Cooling System – Reduces tool wear and prevents thermal expansion during high-speed drilling.

Multi-Spindle Compatibility – Optional configuration allows drilling multiple holes simultaneously for higher efficiency.

Intelligent Feed Rate Control (F Function) – Adjusts drilling speed in real time based on material resistance to maintain perfect hole quality.

Compact Footprint with Industrial Capacity – Designed for workshops with limited space but high performance needs.

Productivity Meets Cost Efficiency

A major advantage of DUOMI CNC's small CNC drilling machine is its impressive return on investment (ROI). Many of our clients in the precision parts industry have reported:

30–50% faster cycle times compared to manual drilling

60% reduction in scrap rate due to consistent hole accuracy

Lower labor costs through automation and unattended operation

Extended tool life with optimized cooling and spindle control

When scaled across large production runs, these savings translate into substantial profitability while maintaining superior quality standards.

Industry Case Study — From Manual to CNC Precision

A DUOMI CNC customer from Singapore, specializing in small aluminum and brass components for sensors, faced increasing rework due to inconsistent hole depth and burrs.

After switching to a DUOMI small CNC drilling machine, the company achieved:

A 45% reduction in production time per batch

Zero misalignment in hole patterns across 10,000 parts

Smoother internal surfaces and higher assembly precision

Their experience reflects a global trend—manufacturers transitioning from manual drilling to automated CNC solutions to maintain competitiveness.

Sustainability and Energy Efficiency

DUOMI CNC integrates energy-efficient servo systems and optimized toolpaths to minimize power consumption. Additionally, precise drilling reduces waste materials and rework, aligning with modern sustainability goals in manufacturing.

This focus on eco-efficient machining not only saves cost but also supports green production initiatives adopted by global supply chains.

Why Choose DUOMI CNC

Reliable Quality: Every machine undergoes strict precision inspection and endurance testing.

Global Support: Technical training, online assistance, and spare part availability ensure continuous operation.

Custom Solutions: Machines can be tailored for specific materials, part dimensions, and production goals.

Worry-Free Warranty: DUOMI CNC stands behind each product with full-service warranty and maintenance support.

The Future of Precision Metal Machining

As global manufacturing moves toward smaller, smarter, and more automated solutions, the small CNC drilling machine will play a critical role in bridging productivity with precision.

DUOMI CNC continues to innovate in this field—developing advanced drilling technologies that combine intelligent automation, digital control, and compact design to meet tomorrow's manufacturing challenges.

Conclusion: Redefining Precision, Efficiency, and Value

If your business depends on high-accuracy drilling for small metal components, it's time to upgrade to a DUOMI CNC small drilling machine.

From stainless steel housings to aluminum connectors, every hole counts—and with DUOMI CNC, every hole is perfect.

Experience the next generation of precision metalworking.

DUOMI CNC — Small Machine, Big Performance.