CNC drilling machines are revolutionizing modern manufacturing, offering unmatched precision, consistency, and efficiency. From small custom shops to large-scale industrial production lines, these machines have become essential for companies that require fast, accurate, and cost-effective hole processing.

But who truly benefits from investing in a CNC drilling machine? The answer spans across multiple industries. Let’s dive into the key sectors and client profiles that can maximize returns from advanced CNC drilling solutions.

1. Metal Tube and Sheet Fabricators

If your business works with metal square tubes, round pipes, angle iron, or flat sheets, a CNC drilling machine is a must-have. Manual drilling is slow, labor-intensive, and prone to human error, while CNC systems can process hundreds of holes with perfect repeatability. Whether you're drilling mild steel, stainless steel, aluminum, or brass, the machine can handle complex drilling layouts effortlessly.

DUOMI CNC machines, for example, offer square tube drilling capabilities with automatic positioning, saving time and reducing material waste. These solutions are especially beneficial for industries where drilling patterns need to be replicated at high speed with minimal deviation.

2. Furniture, Display Rack, and Storage System Manufacturers

Furniture made with metal frames—such as office desks, chairs, shelving, and modern retail displays—requires reliable joint structures. Traditional methods like welding or riveting can be time-consuming and leave messy finishes.

With thermal friction drilling and tapping, CNC drilling machines eliminate the need for additional components like nuts or inserts. You get strong, threadable holes directly on metal tubes, streamlining production and enhancing product aesthetics. DUOMI CNC’s integrated drilling and tapping systems are widely used in the furniture and storage rack industries for this very reason.

3. Fitness Equipment Manufacturers

Companies that produce gym equipment—such as power racks, pull-up bars, crossfit rigs, and rehabilitation machines—use thick-walled steel tubes and require high structural strength. Here, automated CNC drilling machines offer a critical advantage by producing precise holes in strong materials, even at angles or varying depths.

Additionally, high-speed CNC tapping functions eliminate secondary processing, allowing components to be assembled immediately after machining. DUOMI CNC systems offer dual-station, multi-axis platforms that significantly boost output for fitness equipment manufacturers.

4. Automotive and Electric Vehicle Parts Suppliers

From brackets and battery racks to suspension components and engine mounts, the automotive and EV industries rely on high-volume, high-accuracy drilling. These applications often require deep-hole drilling and fine-diameter holes with strict tolerances.

CNC drilling machines support this with programmable drilling patterns, automatic depth control, and minimal burr formation. Whether you're a Tier 1 supplier or a niche parts maker, integrating CNC drilling into your line can improve consistency and support mass production needs.

5. Aerospace, Defense, and Medical Components Manufacturing

Precision is paramount in aerospace and medical manufacturing. Drilling errors as small as 0.05mm can lead to product rejection. CNC micro-drilling machines, like DUOMI’s high-speed 60,000 RPM models, are capable of producing holes as small as 0.03mm with exacting accuracy.

Medical braces, implants, sensor housings, and aerospace brackets can be processed reliably using these industrial CNC drilling machines. Automated tool changers, real-time monitoring, and quality traceability features are crucial in meeting the strict compliance standards of these sectors.

6. General Engineering and Contract Job Shops

For engineering firms handling varied customer projects, CNC drilling systems provide the flexibility to adapt to multiple materials, hole sizes, and layouts. From prototypes to short-run batches, these machines support a wide range of applications with fast setup times and minimal manual intervention.

Even small and medium enterprises (SMEs) can benefit by offering CNC precision drilling as a value-added service, increasing their competitiveness in the global manufacturing landscape.

7. Educational and Technical Training Institutes

With the rapid automation of the manufacturing industry, many vocational schools and technical training centers are integrating CNC drilling machines into their curricula. Students learn the fundamentals of G-code programming, CAD/CAM integration, and hands-on machine operation—preparing them for real-world factory automation.

DUOMI CNC provides affordable, training-friendly models with user-friendly interfaces, making them ideal for educational environments.

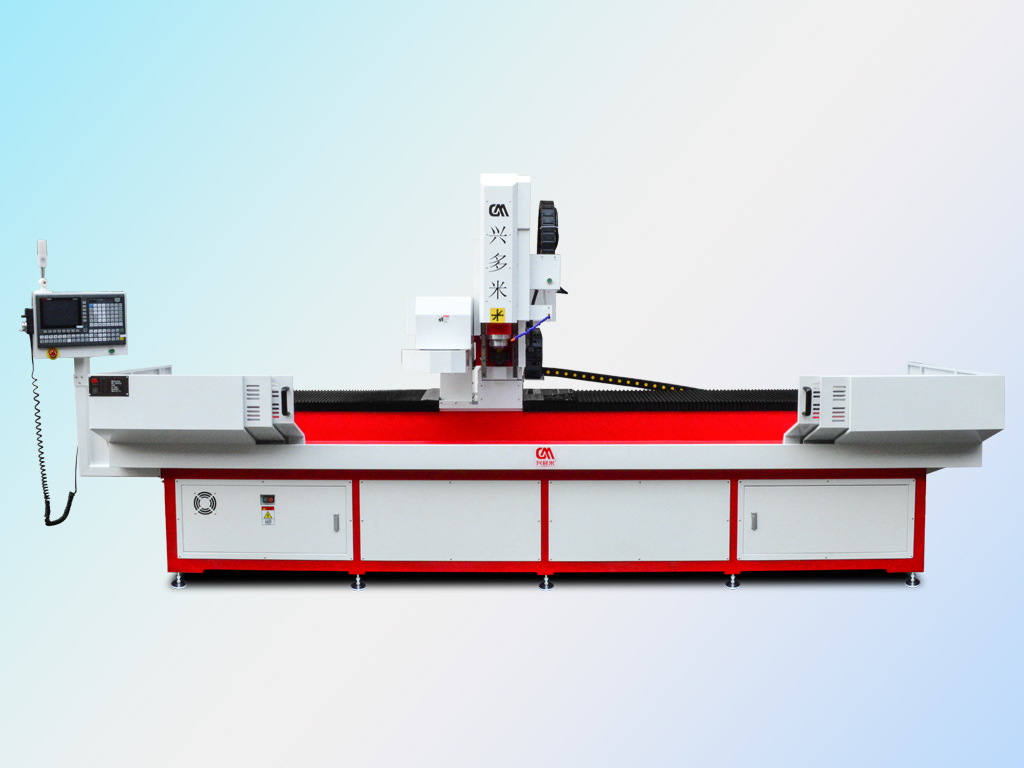

Why Choose DUOMI CNC?

DUOMI CNC is a trusted manufacturer of professional-grade CNC drilling and tapping machines with clients worldwide. Our solutions are tailored for high-performance applications and cover a wide range of use cases, including:

Square and round tube drilling

Thermal friction drilling & tapping

Deep-hole precision micro-drilling

Multi-spindle synchronous operation

Automated loading/unloading options

Integration with industrial robots

We serve global customers in furniture, fitness, automotive, aerospace, and medical industries—delivering machines that drive efficiency, accuracy, and long-term cost savings.

Final Thoughts

If you're still relying on manual drilling or outdated equipment, it may be time to upgrade to an automated CNC drilling system. Not only does it improve your production speed and accuracy, but it also prepares your factory for the future of smart manufacturing.

Whether you're a startup exploring small-scale automation or a multinational looking to boost productivity, DUOMI CNC can provide the right solution for your business.

Contact us today to learn more or request a free sample drilling test!